Fracture

advertisement

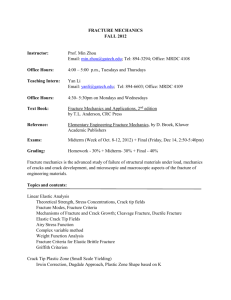

Seminar on Mokashi Imrankhan Sherkhan Guided by: M S Bobji Importance of Fracture Mechanics in Tribology Wear Erosion Surface Formation Fracture Mechanics approach Energy Based : Energy release rate(G) and J integral Stress Based : Stress intensity factor (K) Displacement Based : Crack tip opening displacement (CTOD) Modes of Crack Propagation Energy Approach Potential Energy Repulsion Distance Bond Energy Attraction Equilibrium Distance xo Tension Applied Force Bond Energy l k Compression + + xo Cohesive Force Distance Griffith’s Energy balance approach •First documented paper on fracture (1920) Considered as father of Fracture Mechanics Energy Approach Cont… Surface energy Es = 2(2a B ᵞ) ᵞ -Surface energy per unit area B-Thickness of plate Energy Approach Cont.. Total PE of Body with crack U = UE – Uwork + US Strain Energy System always try to minimize its PE Thick plate is more resistant to fracture or thin? J Integral J Integral over a closed loop = 0 Path independent Displacement Approach Displacement Approach From Hooke’s law, displacement field can be obtained as u 2(1 ) r 1 KI cos sin 2 E 2 2 2 2 v 2(1 ) r 1 KI sin cos2 E 2 2 2 2 where u, v = displacements in x, y directions (3 4) for plane stress problems 3 for plane strain problems 1 Stress Approach Stress Intensity Factor K a for K a for can be obtained from : infinite plate other geometry 1. handbook solution 2. approximate method 3. numerical method Stress near crack tip 3 cos [1 sin sin ] 2 2 2 2r x K y K xy K 3 cos [1 sin sin ] 2 2 2 2r 3 sin cos cos 2 2 2 2r ij a f ij ( ) 2r Plastic zone size Plastic Zone Shapes y plane strain x plane stress Mixed Loading KI K Ic n1 K II K IIc n2 K III K IIIc n3 1 where KIc, KIIc, KIIIc, ni (i = 1, 2, 3) – parameters that characterize material near the concentrator, determined experimentally KI K Ic ni K II = 1 K IIc ni ni K II K IIc ni K III = 1 K IIIc Cont… KI K Ic ni K II K IIc ni K III K IIIc ni 1 (1) Diagrams of the deformed body limiting-equilibrium state the conditions of mixed (I+II), (I+III) fracture mechanisms Curve 1 – according to formula (1) when KIII = 0 and ni = 4, curve 2 according formula (1) when KIII = 0 and ni = 2 Curves 1 and 2 are plotted according to formula (1) when ni = 4 and ni =2 correspondingly FATIGUE FRACTURE Every Coin has two sides… Useful Fracture Metal cutting Rock cutting in Mining “Biting” of candies Unwanted Fracture Fracture of Liberty ships in World war II Fracture of wheels, axles and rails Fracture Avoidance with Proper Use of Material Pyramid of Egypt • • Schematic Roman Bridge Design The primary construction material prior to 19th were timber, brick and mortar Arch shape producing compressive stress stone have high compressive strength Fracture Avoidance with Proper Use of Material (cont’) • Roof spans and windows were arched to maintain compressive loading REFERENCES A book on “Fracture Mechanics” by Prashant Kumar “Introduction to Fracture Mechanics” book by C. H. Wang Finite Element Analysis Stress analysis near crack Quarter point element J- integral