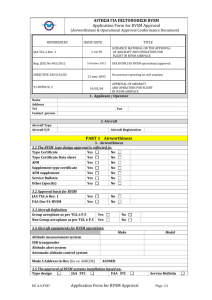

550 RVSM Maintenance.. - flyinginvestments.com

advertisement

LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 1 – MAINTENANCE PROGRAM This manual will be used by LC Joint Adventures LLC to ensure that aircraft approved for Reduced Vertical Separation Minimums (RVSM) will be maintained in accordance with Appendix G of 14 CFR Part 91, within current FAA regulations and to specifications required for RVSM operations. LC Joint Adventures LLC conducts operations with Cessna Citation Bravo(s), Serial Number 550-920, and Serial Number 550-0817, and Citation II Serial Number 5500333 in accordance with 14 CFR Part 91. LC Joint Adventures LLC maintains its aircraft in accordance with 14 CFR Part 43 and 91.409(f)(3). Accordingly, LC Joint Adventures LLC's current inspection program is sufficient to maintain the aircraft systems and equipment in accordance with RVSM requirements. These requirements are tracked by a computerized maintenance-tracking program (CESCOM). Responsibility for compliance with this FAA approved RVSM Maintenance Program and the requirements of the manufacturer's inspection program, lies with LC Joint Adventures LLC through the RVSM Responsible Person. Additionally, LC Joint Adventures LLC's RVSM Responsible Person is responsible for distribution, control and revision of this manual. In the event the RVSM Responsible Person is unable to personally ensure that the compliance with the requirements of this RVSM maintenance program is being accomplished, a qualified aircrew member and/or aircraft mechanic employed by LC Joint Adventures LLC may act as a delegate if specifically designated by the RVSM Responsible Person. Approval of this manual is indicated on approval page of the Table of Contents including the, inspector's signature, office name, number, and location listed. At such time a revision to this program is required the RVSM Responsible Person will submit the revision(s) to the Little Rock FSDO (please reference LC Joint Adventures LLC's OPSPEC/LOA) for review and approval. Upon approval, the RVSM Responsible Person will ensure that each authorized holder of this manual receives and inserts the revision. A copy of this manual is required to be carried aboard each aircraft and available to the flight crew along with the Letter of Authorization when RVSM operations are in effect. Information related to LC Joint Adventures LLC maintenance and inspection procedures for RVSM specific equipment and systems are also contained in this chapter. LC Joint Adventures LLC will use appropriately approved maintenance facilities for its Citation fleet to ensure continued compliance with RVSM requirements on an as needed basis. Revision 2 2-1 23 December 2015 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 2 – MAINTENANCE REQUIREMENTS This RVSM inspection program identifies all aircraft equipment required for RVSM, together with scheduled maintenance requirements for that equipment. For the Citation Bravo, the aircraft manufacturer identifies this equipment and lists it in the Airplane Flight Manual Supplement 55BFM-S25 page S25-5. The Cessna Citation Bravo Maintenance Manual (55BMM; REV. 23; 1 August 2013 or later Revision) outlines the maintenance requirements for RVSM equipment. Only the current revision will be used to accomplish maintenance. For the Citation II (550-0333), two Shadin ADC-6000 Air Data Computers have been installed in accordance with STC ST02115CH. The Instructions for Continued Airworthiness (ICA) are contained in Shadin Document DN2807A-017, a copy of which is appended at the end of this manual. Shadin Flight Manual Supplement Document Number DN2807A-006, Revision B has been inserted into the Aircraft Flight Manual. Only the current revision of these documents will be used to accomplish maintenance. Other maintenance items such as Service Bulletins, Service Letters, and AD's will be tracked using a computerized maintenance-tracking program (CESCOM). To retain approval for RVSM in the Citation II s/n 550-0333 it is necessary to accomplish inspections and maintenance procedures contained in the Shadin ICA, which refer to the Cessna Citation II maintenance manual ATA 34-11 and require recurrent test and inspections every 24 months in compliance with CFR Part 91.411. To retain approval of RVSM in the Citation Bravo aircraft it is necessary to accomplish the following inspections. A special inspection requirement occurs if the airplane is damaged and repaired, painted or polished/buffed in the static port area. The static ports must be inspected to ensure they are within the tolerances (Refer to Task 34-14-00-710). 1. A functional check of the Air Data Systems as per the manufacturer's maintenance manual section 34-14-00 Inspection / Check (Task 34-14-00-710) as part of the scheduled Phase 20 Inspection performed every 24 months. 2. A Pitot and Static Systems Functional Check is included in the Air Data System functional check (Task 34-14-00-710). 3. A static port height check as per the manufacturer's maintenance manual section 34-11-12 Inspection/Check (Task 34-11-12-220) as per of the scheduled Phase 20 Inspection performed every 24 months. 4. A functional check of the aircraft's auto flight control system is not required by the manufacturer's maintenance manual. Revision 2 2-2 23 December 2015 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 5. A functional check of the altitude alerting system is included in the Air Data System functional check (Task 34-14-00-710). 6. A calibration check of the transponder system as per the manufacturer's maintenance manual section 34-54-00 Inspection / Check (Task 34-54-00-730). This is part of the scheduled Phase 21 Inspection performed every 24 months. 3 - MAINTENANCE PROCEDURES: INSTRUCTIONS FOR CONTINUED AIRWORTHINESS (ICA) To ensure the continued airworthiness and height keeping ability of RVSM approved aircraft the RVSM Responsible Person is responsible for ensuring the following practices are accomplished: Avionics components of identical part number may be interchanged freely during the service lifetime of this airframe (subject to the requirements of this RVSM Maintenance Program, the current version of the Citation Parts Manual, or the applicable Instructions for Continued Airworthiness). If alternate equipment part numbers are to be installed, the units must be analyzed on a system level to determine if the new components are acceptable for RVSM. NOTE: The TC holder will make this determination. Cessna Citation Checklist calls out for the pilot to inspect the Pitot/Static areas during the Preflight Inspection. It is imperative that prior to all flights in RVSM airspace, the pilot visually inspects the RVSM Critical Region for obvious damage or deformation to the skin surface. Airframe, static systems and RVSM critical equipment should be maintained in accordance with the airframe manufacturer's inspection standards and procedures, and instructions for continued airworthiness as applicable (including but not limited to the current revision of Cessna Citation Maintenance Manual). Any modification, repair, or design change, which in any way alters the initial RVSM approval, will require a design review by Cessna and FAA engineering. Any maintenance practices which may affect the continuing RVSM approval integrity, e.g., the alignment of pitot/static probes, dents, or deformation around static plates, should be referred to the approving authority or persons delegated by the authority. Only the current revision of technical publications will be used to accomplish maintenance. Currency of Cessna’s technical publications may be verified at cessnasupport.com 4 - REMOVAL / RETURN TO RVSM SERVICE PROCEDURES When RVSM-critical equipment malfunctions are identified, the flight crew shall reference the Aircraft Flight Manual and the MEL for allowable flight operations. Refer to the RVSM Aircraft Flight Manual and Appendix A of this RVSM Maintenance Program for a listing of RVSM-critical equipment. At such time an RVSM related malfunction occurs the aircraft will become non-compliant regarding RVSM operations and the following procedures will be adhered to: Revision Original 2-3 12 September 2014 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 The RVSM Responsible Person or designee and Maintenance personnel will advise the flight crew that all flight plans in RVSM applicable airspace will make reference to RVSM non-compliance (Per FAA InFO 12001 (DATE: 1/18/12) Non-RVSM aircraft must not file a flight plan with an RVSM equipment/capability qualifier (i.e. W for ICAO flight plan)) and indicate that until corrective action is accomplished, the aircraft is not to be operated in RVSM airspace. Flights in RVSM airspace with a non-compliant aircraft are contingent upon prior ATC approval. An entry will be made in the appropriate flight/maintenance record to indicate the aircraft is not compliant with RVSM requirement until such time the discrepancy(s) are corrected. A placard shall be placed on the aircraft instrument panel indicating the aircraft is not RVSM compliant. The wording on the placard will conform with the MEL. (example “ALTITUDE ALERTER INOP. FLIGHT INTO RVSM AIRSPACE NOT AUTHORIZED”). For the aircraft to become RVSM compliant, corrective action must be carried out to identify the failure and/or malfunction of the affected component and must be confirmed and repaired by maintenance action. Upon completion of corrective maintenance and testing, the RVSM Responsible Person or his designee will ensure that the installed placard indicating that the aircraft is not RVSM compliant is removed and an entry made in the aircraft maintenance record, which will return the aircraft to RVSM authorized status in accordance with FAR part 43.9. The maintenance entry will include a statement that the aircraft is “RVSM Compliant.” Should the aircraft be positively identified as exhibiting height-keeping performance errors, the above five (5) bullets must be used to determine the corrective action. Prior to release for operation in RVSM airspace, a height monitoring flight to verify the airplane meets required height-keeping performance will be accomplished. 5 - MAINTENANCE TRAINING LC Joint Adventures LLC does not provide in-house training for maintenance personnel. Specific to RVSM, the Cessna Citation Authorized Service Center personnel have received initial training regarding RVSM requirements. Cessna Citation Authorized Service Centers ensure that recurrent RVSM maintenance training is completed. It is the responsibility of the RVSM Responsible Person or designee for LC Joint Adventures LLC to inquire with the management of the FAA Part 145 maintenance facility to ensure that all personnel performing maintenance on the RVSM systems are properly trained, qualified, and knowledgeable to perform maintenance on RVSM systems. The RVSM Responsible Person or designee will review records of all RVSM related maintenance performed to ensure compliance with the requirements of this program and to ensure continued height-keeping ability of covered aircraft. The RVSM Responsible Person will ensure that the information and certification of the RVSM Compliance Form found in Appendix B of this manual is complete. Any discovered discrepancies shall be resolved prior to using the maintenance facility. Revision Original 2-4 12 September 2014 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 6 – RVSM COMPLIANT TEST EQUIPMENT LC Joint Adventures LLC does not presently own or control test equipment specific to the maintenance or calibration of RVSM equipment. As such, this company will use only Cessna Citation Authorized Service Centers, or other approving agency authorized facilities, operating as certified repair stations under FAR Part 145 who, by virtue of their approval from the aircraft manufacturer or the approving aviation agency, are qualified and responsible for the utilization, calibration, and operation of approved test equipment. LC Joint Adventures LLC will utilize these facilities on an "as needed basis" for maintenance and/or calibrations of RVSM equipment. The RVSM Responsible Person or designee is responsible for ensuring that the following requirements are met, by communicating these requirements to the approving agency authorized facility: 1. Calibration of RVSM test equipment does not exceed 12 calendar months. 2. Traceability of calibrated test equipment to standards of the NIST. 3. Appropriate list of repair station personnel trained in the use of specialized RVSM test equipment is maintained and provided upon request. 4. Adherence to acceptable shop and line maintenance practices. 5. Specific test equipment, as identified in Cessna Citation Bravo Maintenance Manual (55BMM; REV. 23; 1 August 2013 or later Revision), or equivalent acceptable to the FAA is utilized during RVSM maintenance/inspection procedures. The RVSM Responsible Person will ensure that the information and certification of the RVSM Compliance Form found in Appendix B of this manual is complete. The form will be maintained in this RVSM Manual. NOTE: BUILT-IN TEST EQUIPMENT (BITE) TESTING IS NOT AN ACCEPTABLE BASIS FOR USE IN CALIBRATIONS UNLESS IT IS SHOWN TO BE ACCEPTABLE BY THE COMPONENT MANUFACTURER WITH APPROVAL FROM THE PERTINENT AUTHORITIES. 7 - RVSM PARTS AND COMPONENTS CONTROL The RVSM Responsible Person or designee will ensure that all persons responsible for obtaining or replacement of RVSM system components are knowledgeable of the aircraft’s RVSM status and requirements of this Program. Parts and components required for RVSM operations will be procured from the manufacturer of that equipment or from an authorized vendor. The following procedures shall be utilized: 1. The RVSM Responsible Person or designee and Maintenance personnel will ensure that all RVSM related parts and components to be used on the aircraft are the part numbers that are described in this RVSM Maintenance Program and the Citation Bravo Parts Manual, Publication No. 55BPC. 2. The RVSM Responsible Person will ensure that non-RVSM eligible parts are not installed. 3. Maintenance Transaction Records (MTR) will be used to track RVSM related components and maintenance. After the successful installation and testing of any RVSM related component, the RVSM Responsible Person or designee will review the associated MTR and 8130-3 forms to ensure the validity of the installation. Revision Original 2-5 12 September 2014 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 8 - RVSM HEIGHT MONITORING 1. LC Joint Adventures is required to conduct initial height monitoring within six months of the date of issue of the LOA for each aircraft, and must conduct monitoring every two years or within intervals of 1,000 flight hours per aircraft, whichever period is longer by overflight of a Height Monitoring Unit (HMU) or Aircraft Geometric Height Monitoring Elements (AGHME). 2. LC Joint Adventures will document compliance with height monitoring requirements via the aircraft computerized maintenance tracking program. Revision 1 2-6 11 May 2015 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 Appendix A RVSM Critical Equipment for Citation 550-0920 and 550-0817 Qty Manufacturer Model 2 2 Honeywell Honeywell AZ-850 IC-600 2 Honeywell KT-70 Qty 2 1 1 2 Type of Equipment Air Data Computer Altitude Alerter / Auto Pilot (Integrated into IAC) Transponder RVSM Critical Equipment for Citation II 550-0333 Manufacturer Model Type of Equipment ADC-6000 Shadin Air Data Computer SPZ-500 Sperry Auto Pilot Sperry VN-212 Altitude Alerter Honeywell MST-67A Transponder Part Number 7014700-920 7017000-80128 / 7017000-81128 066-01141-1101 Part Number 962860-00-01 4008519-941 4020571-904 066-01143-2101 TCAS for Citation Bravo Qty Manufacturer 1 Honeywell Qty Manufacturer 1 Revision 2 Bendix/King Model Type of Equipment TCAS II (Change 7) TPU-66A TCAS for Citation II Model Type of Equipment TPU-67A TCAS II (Change 7) 2A-7 Part Number 071-01568-0901 Part Number 066-01196-0205 23 December 2015 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 RVSM Critical Areas for Citation 550 Qty Type Description The RVSM critical areas are forward of, and less than, 10 degrees above the highest static port and 20 degrees below the lowest static port, or in less than 12 inches (304.8 mm) of a static port as projected on the airplane. (Refer to 55BMM (Citation Bravo Maintenance Manual) Section 34-10-00 - Figure 1) 2 Static Port Areas Revision Original 2A-8 12 September 2014 LC Joint Adventures, LLC 4500 S. School Ave. Suite M Fayetteville, AR 72701 479-841-4262 Appendix B Name of Facility: Address: City, State, Zip: Country (if non-US): Phone #: Fax #: Years in Business: YES Is this facility a FAA Certified Repair Station? If YES, please give the CRS#: NO Please list any other regulatory agencies from which this facility is authorized (EASA, CAA, DOT, etc.) and the appropriate authorization numbers. Personnel at this facility responsible for RVSM Name Title Phone Number RVSM Certification Status: Are the RVSM personnel trained, qualified, and knowledgeable? Yes or No Is the RVSM test equipment currently calibrated? Yes or No Is the RVSM Test equipment appropriate? Yes or No Does the test equipment conform to NIST standards? Yes or No I certify that the above Statements are true (Responsible person at this facility signs): Name: _ Signature: _ Date:______________________________ Revision Original 2B-9 12 September 2014