Lect3n

advertisement

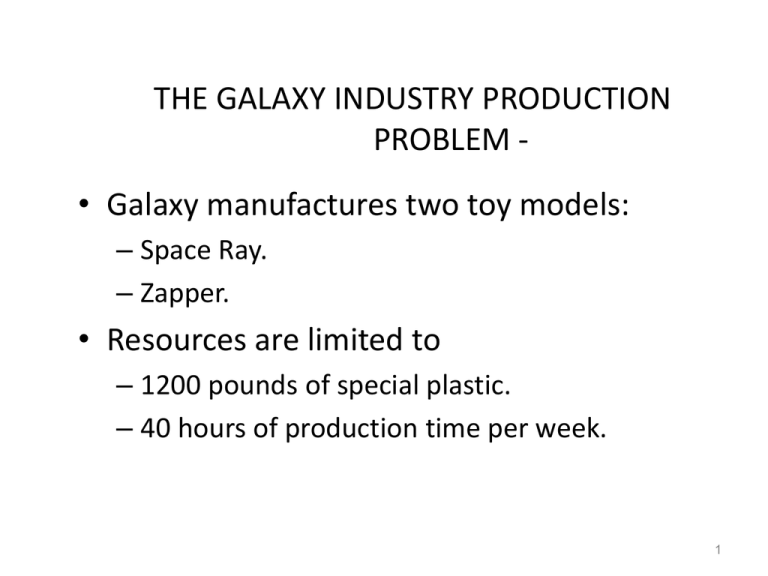

THE GALAXY INDUSTRY PRODUCTION PROBLEM • Galaxy manufactures two toy models: – Space Ray. – Zapper. • Resources are limited to – 1200 pounds of special plastic. – 40 hours of production time per week. 1 • Marketing requirement – Total production cannot exceed 800 dozens. – Number of dozens of Space Rays cannot exceed number of dozens of Zappers by more than 450. • Technological input – Space Rays requires 2 pounds of plastic and 3 minutes of labor per dozen. – Zappers requires 1 pound of plastic and 4 minutes of labor per dozen. 2 • Current production plan calls for: – Producing as much as possible of the more profitable product, Space Ray ($8 profit per dozen). – Use resources left over to produce Zappers ($5 profit per dozen). • The current production plan consists of: Space Rays = 550 dozens Zapper = 100 dozens Profit = 4900 dollars per week 3 Management is seeking a production schedule that will increase the company’s profit. 4 SOLUTION • Decisions variables: – X1 = Production level of Space Rays (in dozens per week). – X2 = Production level of Zappers (in dozens per week). • Objective Function: – Weekly profit, to be maximized 5 The Linear Programming Model Max 8X1 + 5X2 (Weekly profit) subject to 2X1 + 1X2 < = 1200 (Plastic) 3X1 + 4X2 < = 2400 (Production Time) X1 + X2 < = 800 (Total production) X1 - X2 < = 450 (Mix) Xj> = 0, j = 1,2 (Nonnegativity) 6 X2 1200 The plastic constraint: 2X1+X2<=1200 The Plastic constraint Total production constraint: X1+X2<=800 Infeasible 600 Production Time 3X1+4X2<=2400 Production mix constraint: X1-X2<=450 Feasible 600 800 Interior points. Boundary points. • There are three types of feasible Extreme points. points X1 7 We now demonstrate the search for an optimal solu Start at some arbitrary profit, say profit = $2,000... 1200 X2 Then increase the profit, if possible... ...and continue until it becomes infeasible Profit =$5040 4, Profit = $ 3, 000 2, 800 600 X1 400 600 800 8 1200 X2 Let’s take a closer look at the optimal point Infeasible 800 600 Feasible Feasible region region X1 400 600 800 9 Summary of the optimal solution Space Rays = 480 dozens Zappers = 240 dozens Profit = $5040 – This solution utilizes all the plastic and all the production hours. – Total production is only 720 (not 800). – Space Rays production exceeds Zapper by only 240 dozens (not 450). 10 Chapter 3: Linear Programming Sensitivity Analysis Sensitivity Analysis What if there is uncertainly about one or more values in the LP model? 1. Raw material changes, 2. Product demand changes, 3. Stock price Sensitivity analysis allows a manager to ask certain hypothetical questions about the problem, such as: How much more profit could be earned if 10 more hours of labour were available? Which of the coefficient in model is more critical? Sensitivity Analysis Sensitivity analysis allows us to determine how “sensitive” the optimal solution is to changes in data values. Is the optimal solution sensitive to changes in input parameters? This includes analyzing changes in: 1. An Objective Function Coefficient (OFC) 2. A Right Hand Side (RHS) value of a constraint Limit of Range of optimality • Max Ax + BY • Keeping x, Y same how the object function behaves if A, B are changed. • The optimal solution will remain unchanged as long as An objective function coefficient lies within its range of optimality There are no changes in any other input parameters • If the OFC changes beyond that range a new corner point becomes optimal. • Generally, the limits of a range of optimality are found by changing the slope of the objective function line within the limits of the slopes of the binding constraint lines. • Binding constraint • Are the constraints that restrict the feasible region Graphical Sensitivity Analysis We can use the graph of an LP to see what happens when: 1. An OFC changes, or 2. A RHS changes Recall the Flair Furniture problem Sensitivity to Coefficients x1 + x2 < 8 Max 5x1 + 7x2 Example 1: Max 5x1 + 7x2 s.t. x1 6 2x1 + 3x2 < 19 x1 + x 2 < 8 x1 > 0 and x2 > 0 x1 < 6 Optimal solution: x1 = 5, x2 = 3 2x1 + 3x2 < 19 Feasible region Sensitivity to Coefficients Range of optimality for c1 Compute the range of optimality for c1 in Example 1. The slope of an objective function line, Max c1x1 + c2x2, is -c1/c2. The slope of the binding third constraint, x1 + x2 = 8, is 1. The slope of the binding second constraint, 2x1 + 3x2 = 19, is -2/3. Find the range of values for c1 (with c2 staying 7) such that the objective-function line slope lies between that of the two binding constraints: Example 1: -1 < -c1/7 < -2/3 Max 5x1 + 7x2 Multiplying by -1, 1 > c1/7 > 2/3 s.t. x1 < 6 Multiplying by 7, 7 > c1 > 14/3 2x1 + 3x2 < 19 x 1 + x2 < 8 x1 > 0 and x2 > 0 Sensitivity to Coefficients Range of optimality for c2 Likewise, compute the range of optimality for c2 in Example 1. The slope of the binding third constraint is -1. The slope of the binding second constraint is -2/3. Find the range of values for c2 (with c1 staying 5) such that the objective-function line slope lies between that of the two binding constraints: Example 1: -1 < -5/c2 < -2/3 Example 1: Max 5x1 + 7x2 Max 5x + 7x Multiplying by -1, 1 > 5/c2 > 2/3 s.t. x < 6 s.t. x1 < 6 Inverting, 1 < c2/5 < 3/2 2x + 3x < 19 2x1 + 3x 2 < 19 xx1 ++ xx2<< 8 8 , xx1 >> 00 and and xx2> >0 0 Multiplying by 5 5 < c2 < 15/2 1 2 1 1 1 2 1 2 2 Sensitivity to Coefficients Graphical solution of Example 1 1200 Cutting & Dyeing 0,1062 FinishingLine Max 7S + 9D 7/10S+1D<=630 (Cutting & dyeing) 1/2S+5/6D <=600 Sewing 1S+2/3D<=708 Finishing 1/10S+1/4D<=135 Inspection & Packaging 1000 800 0, 630 600 400 200 708,0 0 0 200 400 600 800 900,0 1000 Optimal solution: S=540,D=252 1. objective function 2. Cutting Line 3.Finishing Line This point will be an optimal solution as long as: slope of line A <=slope of the objective function <= slope of line A i.e. the slope of the objective function should be in between these two lines • • • • • • • • • • • • • 7/10S+D=630 (C&D) D=-7/10S+630 S+2/3D=708 (Finishing) D=-3/2S+1062 -3/2<=slope of objective function <=-7/10 -3/2<=-Cs/Cd<=-7/10 if we put profit contribution of delux bag same i.e 9 -3/2<=-Cs/9<=-7/10 Cs>=3*9/2 Cs>=27/2 Cs>=13.5 Cs>=63/10 Cs>=6.3 • 6.3 <=Cs<=13.5 (limits for Cs with same optimal solution) • Similarly the keeping profit contribution of S bag constant. Cs=10 • 6.67<=Cd<=14.29 (range of optimality) • If both the Cs, Cd are changed simultaneously (i.e S bags to 13, D bags to 8) • Calculate the slope again: • -cs/cd =-13/8=-1.625 • -3/2<=-Cs/Cs<=-7/10 • now -Cs/Cd=-1.625 which is less than -3/2 which is not acceptable according to above equation hence this means if we change the both cofficient than 540 and 252 would not be the optimal solution. • Multiple changes – The range of optimality is valid only when a single objective function coefficients changes. – When more than one variable changes we turn to the 100% rule 100% RuLE For each increase (decrease) in an objective function coefficient, calculate (and express as a percentage) the ratio of the change in the coefficient to the maximum possible increase (decrease) as determined by the limits of the range of optimality. Sum all these percent changes. If the total is less than 100 percent, the optimal solution will not change. If this total is greater than or equal to 100%, the optimal solution may change. Example • 6.3 <=Cs<=13.5 (limits for Cs with same optimal solution • Suppose: • S is changed from 10$ to 11.50$; • Range of optimality from the sensitivity analysis : • allowable upper limit for S= 13.49; • Value of S =$10 • Allowable increase in S= 13.49-10 =3.49 • the increase in percentage is 1.5*100/3.49=42.86% of allowable increase Example • • • • • • • 6.67<=Cd<=14.29 (range of optimality) For D allowable lower limit is 6.66 allowable Value of D=9 allowable Decrease =9-6.66=2.33 D is reduced from $9 to $8.25 for the present case D is reduced from $9 to $8.25 for present case =0.75/2.33*100= 32.14 of allowable decrease. • sum of allowable increase and decrease is 42.86% + 32.14% <100% hence optimal solution is still valid S=540 and D-252. Effect of change of the right hand side of the constraint. • Any change in a right hand side of a binding constraint will change the optimal solution. • Any change in a right-hand side of a nonbinding constraint that is less than its slack or surplus, will cause no change in the optimal solution. Keeping all other factors the same, how much would the optimal value of the objective function (for example, the profit) change if the right-hand side of a constraint changed by one unit? Effect of change of the righ hand side of the constraint. • suppose if additional 10 hrs is added to cutting and dyeing constraint • 7/10S+1d<=640 ??? • Feasible region extended, find extreme point using intersection of two lines • S=527.5 ,D=270.75 Max 10S+9D • Profit= 7711.75 which is 7711.75-7668.00 =43.75 • Increase in profit/hr = Dual Price • It is the improvement in the optimal solution per unit increase in the RHS of constraint • If dual price is negative this means value of objective function will not improved rather it would get worse ,if value at rhs of the constrain is increased by 1 unit . for minimization problem it means cost will increase by 10. Reduced Cost is: • The minimum amount by which the OFC of a variable should change to cause that variable to become non-zero. • The amount by which the objective function value would change if the variable were forced to change from 0 to 1. Sensitivity Analysis for a Minimization Problem Burn-Off makes a “miracle” diet drink Decision: How much of each of 4 ingredients to use? Objective: Minimize cost of ingredients Data Units of Chemical per Ounce of Ingredient Ingredient X A 3 B 4 C 8 D 10 > 280 units Y 5 3 6 6 > 200 units Z 10 25 20 40 < 1050 units Chemical $ per ounce of ingredient $0.40 $0.20 $0.60 $0.30 Requirement Min 0.40A + 0.20B + 0.60C + 0.30D ($ of cost) Subject to the constraints A+B+C+D > 36 (min daily ounces) 3A + 4B + 8C + 10D > 280 (chem x min) 5A + 3B + 6C + 6D > 200 (chem y min) 10A + 25B + 20C + 40D < 1050 (chem z max) A, B, C, > 0