Washing

advertisement

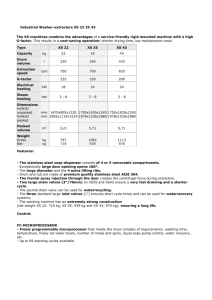

27˝ Front Loader (Columbus Combo) 16/June/2003 Washing Machine Division 1 2 Variety Capacity of Condensing Combo 24˝(600mm) Width ?(developing) 27˝(686mm) Washing Capacity 5kg 6.5kg 7kg 8kg 10kg Drying Capacity 2.5kg 3kg 3.5kg 4kg 5kg Direct Drive system Brushless Motor system Quiet washing Foam Removal system(Suds-free) Water Circulation system Optimum Senseclean™ washing (Fuzzy Logic Control system) Biggest Wash&Dry Capacity Powerful RollerJets(w/ Washing-Ball) Condensing Drying system 3 1. Design Look & Spec. Design Look Spec. Category Model Name Color Water Heater Wash/Rinse Temperature Cycles Delay Wash Max. Spin speed RollerJets Water Circulation Cabinet Top Door Trim Window Cover Combo WM-3632HW White YES 6 options 9 19 hours 1200 RPM YES YES Porcelain Silver YES WM : Front loading Washer 36 : 1200 rpm, Combo 32 : Columbus Ⅱ(Wave Panel) H : Heater Columbus Ⅱ W : White 4 1. Product Differentiation Dry Capacity Dry(ℓb)[kg] Tub Material Dry Heater(W) Columbus Combo WD-3243RHD Equator Quietline 11[5] 6[3.0] 6[3.0] 5[2.5] Plastic Stainless Stainless Stainless 1200 1200 650+650 1300 90 74 70 75 60 52 49 54 15 28.5 21 28 Performance *Dry Performance(%) **Energy Use(%) Water(ℓ) *test condition : dry time-90min., dehydration-57%, load –8 lbs. **efficiency : moisture / energy(kwh) 2. Direct Drive system LG recently adopt new advanced technology so called “Direct drive” system to its new washer and wash & dry combo unit . Without belt and belt pulley, motor itself is connected to the drum tub. It results a great improvement in reducing noise and improving energy efficiency. 5 6 2. Brushless Motor system Not like conventional washer that using brush DC motor, LG washer use Brushless DC motor in it so that the durability, quietness and efficiency is greatly improved. Conventional Motor (Universal motor) Rotor (Magnetized by current) (with brush) LG’s New Motor (Direct Drive) (brushless) Rotating Shaft Stator (Magnetized by current) Coil Stator (Magnetized by current) Coil Rotor (permanentmagnet) Brush Brush delivers electric signals to rotate the coiled rotor. ● Brush makes frictional sound. ● Coiled rotor needs electricity. ● Brush abrades and needs replacement. Rotor is a permanent magnet. Multi-coiled stator is big and powerful enough to replace the pulley. ★ Powerful & Reliable control ★ Minimum vibration & noise ★ Optimum energy consumption 7 2. Quiet Washing Low noises by removing brush and belt, Low vibration by more stable balancing system Unique no brush and no belt Direct Drive Front Loader Conventional Lowest Noise & Vibration Level Washing : 53dB , Spinning : 67 dB Direct Drive (*Sound Power Pressure) • Low and • No Friction Noise • Stable Balancing System Low Noises Quiet and durable motor by removing Brush that makes unpleasant noises 75 18% Low Vibration More stable Balancing system by moving Motor to the center of system Conventional system Columbus DD system 2. Optimum Senseclean™ washing To get the best washing performance, optimal time is determined by the water temperature, the selected washing temperature, and the size of the load. 8 9 2. Control Process : Mechanical vs. Fuzzy Logic Mechanically controlled washers rpm Not enough High Spin Time max Not reached Max Spin rpm. Too much Vibration Spin at 70dB (normally) 100 Low Spin Performance Fixed Spin Time Gap of actual Performance of Spin LG Fuzzy Logic control rpm High Spin max Load detection Balance Check Balancing Balance Check Balancing Spin at 60dB 100 Feed-Back System Automatic control of the Spin Time 8/28 10 2. Auto-Balancing Feed Back System Sensor detects and makes clothes balanced so as to achieve lower noise level. High Spin rpm Load detection Unbalance detection Balancing Feed-Back System Small load rpm Large load ref Time 11 2. Unbalance Sensing theory * During spin cycle, if total amount of rpm changing (speed changing) is over the allowed level which is set in the Micom, the washing machine starts an untangling cycle. ( i.e, if the Micom decides that the load is out of balanced, the washing machine starts the untangling course.) * If the total amount of rpm changing ( Δspeed changing) is still incorrect after the untangling course has been carried out the required times, it displays the “ UE” error message. 3.Period getting the eccentricity Data rpm 100 rpm 4.Spinning start Sensing period 50 rpm 2.Untangling O.K 5sec. 10sec. 1.Rinsing finish /Spinning start 5sec. 5sec. 12sec. 2. Suds-Free System Improve “wash/rinse” and “spin” performance by detecting and removing excessive suds in the drum 12 13 2. Suds sensing function During Washing cycle Suds sensing during washing cycle is done by water level change regardless of motor operation. • If frequency is lower than 23.3KHz, the machine decides it as a suds problems. • In Perm press, Delicates, Wool/Silk, or Hand wash cycle, it does not work. Sensing and removing Suds during Washing cycle Washing Process Lower than 23.3KHz Draining for 1minute Breaking for 2minute Fill in water for 1minute Finish 3times Total Required time : about 12minutes 14 2. Suds sensing function During Spinning cycle • The micom recognizes it as suds problem when: 1) the spinning speed does not reach 270rpm in 10 sec. 2) the water pressure is lower than 24.0kHz during intermittent spin. 3) the water pressure is lower than 24.4kHz during high speed spin. • When suds is detected, spinning is stopped and the Suds remove program is started. And then the Water supplying and draining are proceeded until suds is not detected. Sensing and removing Suds during Spin cycle Spinning Process Suds sensed Drain for 2 minute Fill in water for 1 minute Breaking for 2minute Finish 3times 15 2. High Cleaning Performance RollerJets • The washing balls increase cleaning power by shooting out water this decreases laundry rubbing together and thus reduces damage to your laundry. Heavy Lifter ▶ Powerfully lift a bulky laundry Circulation System • It is Circulation Shower System that sprays water from the top down decreasing water, detergent and energy consumption while at the same time increasing washing power. Shower Connector Hole ▶ Shower Fn. (At peak point) Ball ▶Bearing Fn. (Decrease rubbing) Inside of the drum 16 2. Condensing Dry system A condensing dryer takes the moist air released from your laundry and mixes it with cool air. This process returns the moisture to water, which is pumped away to a drain line. The some of steam is away througth the dispense and vent. Largest washer with dryer Performance 10kg washer with dryer is first in the world. •Use less condensing water than any other washer with dryer. 1 •High dry performance 3 •High energy efficiency 2 4 1:dry duct 2:tub 3:fan 4:condensing duct •2-step safety equipment 17 3. Water Circulation Drain Pump Circulation Pump Shower Connector ●Feature 1) Spray detergent solution and water onto the load Inside of the drum over and over. 2) Clothes are soaked more quickly and thoroughly during ●Working Description 1) During Wash cycle: wash cycle. 3) The detergent suds can be 0~3 min - Pump On removed more easily by the 3~10 min - 20 sec On water shower during 10 sec Off 2) During Rinse cycle: always On 3) Start operation after water is supplied rinse cycle. 4) Uses both water and detergent more efficiently. 5) Is used to wash inside of the door window. 18 3. Door Lock Switch ●Feature Unlock ②Lock 1) Normally be unlocked, so that the washer can be opened by hand even if the washer has no power supply. 2) Instantaneous locking/ unlocking. ①Lock 3) Enable to open from inside for safety. ●Working Description 1) Stop →Operation: 1 pulse applied to Lock 2) Operation →Stop: 2 pulses applied to Unlock * Power failure during operation: lock for 5 min ●The door cannot be unlocked if: 1) The drum is moving. 2) The water temperature exceed 45 degrees C. 3) The water level exceed a certain point. 19 3. Ball Sensor DIODE(emitting light) ●Feature BALL 1) Detects unbalanced load. light 2) Prevents a striking/walking. 3) Drum stops if excessive CASE tub hits the ball sensor. HOLE Ball Sensor vibration occurred and then TR(Sensing light) ●Working Description 1) Senses within 60~300 rpm during spin. 2) If the tub hits the ball sensor then drum stops rotating and rebalance the load. 3) Sensor detects out-of-balance and makes loads balanced to achieve lower noise and vibration. 20 4. Control Panel 1 DOOR LOCKED lamp 2 3 STATUS INDICATOR EST. TIME REMAINING 4 POWER button 6 5 OPTION buttons WASH/RINSE temp. SPIN SPEED SOIL LEVEL button 7 8 DRY CHILD button LOCK 9 CUSTOM PROGRAM button SELECTOR knob 10 CYCLE START/PAUSE button 21 5. Test Operation ① Preparation for washing •Connect the power plug to the outlet. •Connect the inlet hose. ② Press the POWER button •In case of NORMAL program. ⑧ Power off and open the door ③ Press the START/PAUSE button ④ Check the water supply ⑤ Check automatic reverse turn •Listen for clicking sounds to determine if the door has locked. •Check if water is suppied through the detergent dispenser. •Check if the drum rotates clockwise and counterclockwise. ⑧ Press the START/PAUSE button ⑦ Check drain and spin ⑥ Check the water heating •Press the POWER button twice the restart. •Press the SPIN SPEED button. •Press the Start/Pause button. •If SVC is needed during check, remove the remaining water by pulling out the hose cap. • Listen for clicking sounds to determine if the door has unlocking. •Press the WASH/RINSE button and the present temperature will be displayed. * BEFORE PERFORMING SERVICE 1. Be careful of electric shock when disconnecting parts for while troubleshooting. 2. The voltage of each terminal is 120V AC and DC when the unit is plugged in. 3. First of all, check the connection of each electrical terminal with the wiring diagram. 22 6. Wiring Diagram Fan motor 7. QC Test Mode 23 * The washer must be empty and the controls must be in the off state. ** Even if you press the button to check inlet valve, inlet valve does not operate until the drum completely stop from spinning. 8. Error Display 24 8. Error Display 25 8. Error Display 26 9. Troubleshooting 27 9. Troubleshooting 28 9. Troubleshooting 29 9. Troubleshooting 30 10. Disassembly instruction 31 10. Disassembly instruction 32