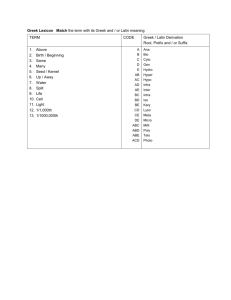

glast lat acd peer review

advertisement