HPM Field-Test Instrumentation System

advertisement

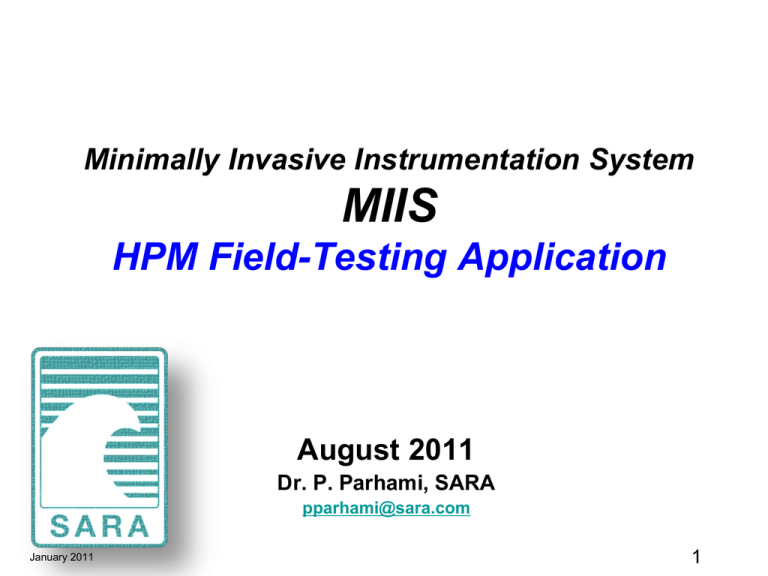

Minimally Invasive Instrumentation System MIIS HPM Field-Testing Application August 2011 Dr. P. Parhami, SARA pparhami@sara.com January 2011 1 Purpose of Our Visit • Introduction to a new class of instrumentation system under development which can provide verification of HPM effects and M&S in operational environments – Minimally invasive – Massively parallel – ~10X lower cost per parallel channel June 2011 2 Introduction to SARA • Diversified R&D company – DETEC: TREM, GTIM, mmTarget Board • EMP Products and Services – Facility EMP hardening, test services > MIL-STD-188-125 – Aircraft EMP hardening, test services > MIL-STD-3023 draft – Instrumentation system, data management workstations • HPM – Advanced HPM antennas June 2011 3 SARA is a Leading Innovator in HPM/HPRF Antennas Flat Aperture Waveguide SidewallEmitting Antenna (FAWSEA) • Unusually low-profile allows it to fit into shallow-depth airborne platforms. • HPM-tested 100% successful at KAFB. • Superb high-power handling and gain. • Designs adaptable to a very wide range of aperture aspect ratios. • US Patent # 7,528,786. 100+ MW class HPM World’s 1st Fully-Steerable HPM Antenna • • • • • • • • • Supports engagements with moving targets High-gain, rapidly-steerable beam Experimentally-validated. In use by MAXPOWER US Patent # 6,559,807. GW-class HPM Multi-kW HPRF, CW or long pulse GW-class HPM Highly-Deployable, Field-Replaceable, Broadband HPRF Antenna for Close-range DEW. Curved Aperture Waveguide SidewallEmitting Antenna (CAWSEA) • Supports portal screening for human-borne IEDs. • Circularly-polarized couples to a wider variety of This curved version of the FAWSEA enables even more Points-of-Entry (PoEs) than linear-pol antennas. conformal fits to many highly-compact airborne platforms. • Minimizes exposure of U.S. forces to potentially Novel feed system compensates for aperture phase error. hostile bomb incidents. Superb high-power handling (like FAWSEA) and gain. • Stores compactly; easily-replaceable in the field. Designs adaptable to a very wide range of aspect ratios. Agenda • A cost-effective instrumentation system is needed for operational environments – Able to measure >100 of parallel channels – Uses minimally invasive sensors • Introducing MIIS – A new test paradigm – Under development (DTRA sponsorship) • MIIS-HPM concept – Offering leap forward in capability in ~ 1 year June 2011 5 Need Better Understanding of HPM Coupling and Propagation • Need to accurately estimate HPM energy at target locations in operational environment – Minimally invasive (minimal perturbation) – Correlation to laboratory effects testing – Validate M&S codes • Candidate operational applications: – IED defeat: Impact of lossy and inhomogeneous ground on HPM beam pattern – Counter Electronics: HPM coupling to complex unhardened structures – Car stopping: HPM coupling to vehicle cables June 2011 6 HPM Field Testing Shortcomings • HPM antenna patterns are estimated through M&S and validated in anechoic chambers • Field patterns vary greatly in presence of inhomogeneous ground, complex structures, random clutter, … • Limited number of sensors used in today’s field testing leave many questions unanswered: – What was the actual HPM field pattern? – Where were the sensor probes in relation to the pattern Max, Min? – Where were the sensor probes in relation to the rep-rate timing? – How distorted were the measured fields due to the sensor cables? June 2011 X X X 7 MIIS HPM Application Example Near real-time monitoring of HPM field pattern or coupling Moving HPM Platform Sensor matrix form a wireless network Ethernet Cable Via balanced E&H Stratton-Chu A.I. From file: CAWSEA_groundspot_150ft_altitude.mph Control Computer Digital F.O. MIIS node integrated field sensor Wi-Fi Router June 2011 8 Existing HPM Measurement Systems • DETEC-sponsored “HPM Sensor Suite” 30 parallel channels (EG&G) – Analog fiber optics lines bring back sensed signals to a shelter full of digitizers – Too expensive to expand beyond 30 parallel channels – Too invasive for field applications > coax connection (sensor to analog F.O. transmitters) – Limited to the range of analog F.O. lines – Time consuming to deploy • DETEC-sponsored Field Strength Sensor Network (FSSN) – 8 parallel wireless nodes, developed for long term operation > Custom node hardware – Not cost effective for 100+ channels – Not designed for internal meaurements June 2011 9 Agenda • A cost-effective instrumentation system is needed for operational environments – Able to measure >100 of parallel channels – Use minimally invasive sensors • Introducing MIIS – A new test paradigm – Under development (DTRA sponsorship) • MIIS-HPM concept – Offering leap forward in capability in ~ 1 year June 2011 10 Traditional Instrumentation Architecture Shield modification Aperture System Under Test Excitation Signal Transmitter Fiber Optics Analog Tansceiver ••• Control Computer Analog conducting line Digital conducting line Fiber Optics Analog Transceiver Fiber Optics Analog Transceiver Sensors ••• Recording Instrumentation Fiber Optics Analog Transceiver ••• Analog fiber optics line Digital fiber optics line Digital wireless link June 2011 11 MIIS Revolutionary Architecture Aperture System Under Test Excitation Signal Transmitter Digital Optical Link Digital Optical Link Wireless Router Interface Node 1 Interface Node 2 Sensors Control Computer ••• Analog conducting line Digital conducting line ••• Interface Node n Analog fiber optics line Digital fiber optics line Digital wireless link June 2011 12 Maximum Reusability for HPM Applications Applications Applications Applications Control Software • DTRA MIIS Backbone • Calls to the Backbone control and communication toolbox Custom needs for each class of applications Reusable Rapidly Deployable Digital Network • • • • Daisy chained digital F.O. Wi-Fi links Maximum use of COTS standards and components Common control and communication toolbox for all applications Sensor Heads Sensor Heads Sensor Heads Sensor SensorHeads Heads • • Application specific detection hardware Interfaces with Backbone interface MIIS Backbone, EMP Control, and CWI sensor head currently under development (sponsored by DTRA) June 2011 13 Agenda • A cost-effective instrumentation system is needed for operational environments – Able to measure >100 of parallel channels – Use minimally invasive sensors • Introducing MIIS – A new test paradigm – Under development (DTRA sponsorship) • MIIS-HPM concept – Offering leap forward in capability in ~ 1 year June 2011 14 HPM Field-Test Instrumentation System • HPM field test requirements: – Simultaneously measure field components at many distributed locations > ~100 or more locations, spread over ~100s meters – – – – – – June 2011 Reduce cost/channel by ~ 10X Control computer placed >> 100 meters away Measure true field versus perturbed field Rapidly deployable sensor matrix Survive HPM environment GPS location and timing 15 MIIS HPM Application Example Near real-time monitoring of HPM field pattern or coupling Moving HPM Platform Sensor matrix form a wireless network Ethernet Cable Via balanced E&H Stratton-Chu A.I. From file: CAWSEA_groundspot_150ft_altitude.mph Control Computer Digital F.O. MIIS node integrated field sensor Wi-Fi Router June 2011 16 HPM Sensor Interface Node Concept SARA IR&D • Sensor node control processor: – – – – – – Low Power Microprocessor Multi-channel A/D 16+ GB or more static memory Wireless and digital F.O. Comm Interface with third party current probes Size of a deck a cards! • Sensor node with integrated 3-axis field sensor: – Narrowband HPM envelop – Wideband HPM waveform June 2011 17 Summary/Feedback • HPM Laboratory Effects data and M&S results need to be validated in operational environments – Radiating over lossy & inhomogeneous ground – Coupling to complex structures • MIIS an important piece of the puzzle! – – – – – June 2011 Economical (10X savings/channel) Massively parallel Minimally invasive, minimally intrusive Digital backbone and EMP application under development HPM sensor prototypes under development (SARA IR&D) > Uses the identical digital backbone 18