jose jeffrey wayne maybay

advertisement

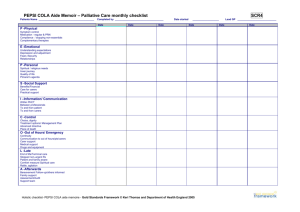

JOSE JEFFREY WAYNE MAYBAY Atabayan, Tigbauan, Iloilo, Philippines, 5021 Almarai Company, Al Nakheel Dairy Farm, Riyadh, K. S. A. josejeffreyw_maybay@yahoo.com.ph / Jose.Maybay@almarai.com 00-966-560884316 PERSONAL STATEMENT I am a highly motivated, responsible, hardworking individual. Capable in effectively organize coworkers and increase productivity with a track record of achieving results within budget. Known for motivational and leadership skills. PROFESSIONAL WORK EXPERIENCE Almarai Company since 15th August 2009, ISMC (ISO Management System Coordinator) of Al Nakheel Diary Farm, Riyadh, KSA. DUTIES & RESPONSIBILITIES Reporting directly to the Farm Manager and to the Quality Assurance Manager of Almarai Company Farming Division in implementing the 4 Management Systems. ISO 9001, ISO 22000, ISO 14001 and OHSAS 18001. ISO 9001 - 2008 Ensure documentation and procedures are properly observed in all areas of the Farm. Dairy Plant, Feeding, Health and Breeding, Young Stock and Dry Stock and Warehouse. Carry out audits as per audit plans. Prepare and assist activities requested by the Farm Management. Conduct trainings and tool box talk type trainings. ISO 22000 Ensure that proper milking routine is always in place at all times. Oversee milk quality is within company’s specifications. Carry out hygiene and housekeeping audit in all areas of the farm. Ensure critical control points in the Milking Parlour are properly adhered; Strip foremilk, milk filter changing, milk transfer temperature monitoring, milk storage & antibiotic residue test should be negative. Conduct Food Safety audit and trainings. Ensure cows release from medics (treatment area) area who had been treated with antibiotic are delvo test negative. Ensure that no antibiotic treatments are carried out in parlour clinics. ISO 14001 Ensure environmental policies are adhered. Monitors waste and reusable or recyclable waste are sold. Ensure waste awareness and energy and water conservations are in place. Carried audits and spot check inspection in areas of the farm. OHSAS 18001 Carry out risk assessment. Conduct health and safety audits. Carry out health and safety inspections on all areas of the farm. Conduct health and safety training. E.g. Safe Chemical Handling, Safe Animal Handling etc. Conduct emergency response drills; Fire Drill, Chemical Spillage Drill etc. Ensure fire alarms and fire equipments are inspected as per frequency. Staff awareness on safe working place. QUALITY CONTROL MANAGER (May 2006 –January 2007) Mahmood Saeed Beverage Industry (Canning and Bottling Plant) Phase 3, Industrial Area, Jeddah Kingdom of Saudi Arabia Duties and Responsibilities: Ensure Total Quality Management is in place. Update Management periodically on quality performance. Ensure that HACCP (Hazard Analysis Critical Control Points) is strictly implemented and done. Ensure always that all Finished Goods are Safe Quality Food. See to it that Water Treatment Plant, Waste Water Treatment Plant, Syrup Production, CO2 Plant and Quality Assurance sections are always focused with respect to Plant Operations. Conduct weekly good manufacturing practices (GMP) audit. Identify potential hazards and implement action plans to eliminate issues. Ensure that operational safety is always observed, being safety is one of the priority measure in operations. Report to Management the raw materials yield / loss weekly. Ensure that standard SOP set by Mahmood Saeed Beverage Industry are properly implemented and observed. Continuously update laboratory procedures based on the implementing guidelines of the industry. See to it that the incoming raw materials are all within specification prior to usage. Coordinate with the suppliers regarding raw materials updates and advisories. Prepare yearly Capital Expenditures Plan (Laboratory Equipments) for QC Lab., Quality Assurance Lab., Water Treatment Plant, Syrup Room, CO2 Plant Lab. and Microbiological Lab. Work hand in hand with Production Department in Plant operations. Act as Plant Manager during the absence of the MSBI Plant Manager. QUALITY CONTROL MANAGER (January 2002 – December 2004) Saudi Industrial Projects Company (SIPCO- Canning Plant) Pepsi Cola, Jeddah Kingdom of Saudi Arabia Duties and Responsibilities: Ensure Total Quality Management is in place. Update Management periodically on quality performance. See to it that Water Treatment Plant, Waste Water Treatment Plant, Syrup Production, CO2 Plant and Quality Assurance sections are always focused with respect to Plant Operations. Ensure that HACCP (Hazard Analysis Critical Control Points) is strictly implemented and done. Ensure that water used in all auxiliary equipments(Boilers, Cooling Towers, Chillers, Heat Exchanger etc.) are properly tested and in compliance to equipments required parameters. Ensure always that all Finished Goods are Safe Quality Food. Conduct weekly good manufacturing practices (GMP) audit. Identify potential hazards and implement action plans to eliminate issues. Ensure that operational safety is always observed, being safety is one of the priority measure in operations. Report to Management the raw materials yield / loss weekly. Ensure that standard SOP set by Pepsi Cola International is strictly followed. See to it that the Plant complies with the standard set by PCI (Pepsi Cola International) with or without Plant Audit. Continuously update laboratory procedures based on the implementing guidelines set by the Management and PCI. See to it that the incoming raw materials are all within specification prior to usage. Coordinate with the suppliers regarding raw materials updates and advisories. Prepare yearly Capital Expenditures Plan (Laboratory Equipments) for QC Lab., Quality Assurance Lab., Water Treatment Plant, Syrup Room, CO2 Plant Lab. and Microbiological Lab. Work hand in hand with Production Department in Plant operations. QUALITY CONTROL SHIFT SUPERVISOR (January 1994 – May 1998) Saudi Industrial Projects Company (SIPCO - Bottling) Pepsi Cola, Jeddah Kingdom of Saudi Arabia Duties and Responsibilities: Ensure Quality Control Policies had been properly implemented. Ensure that all Critical Control Points are strictly done. Control proper manning within shift. Coordinate with Production Department regarding production schedule. Reports to Quality Control Manager on QC activities and status. Ensure that proper housekeeping is always maintained at all times within the laboratory and in the production line. Ensure that instruments and gauges used in the analysis and production operations are properly calibrated and maintained periodically. Ensure that water used in all auxiliary equipments(Boilers, Cooling Towers, Chillers, Heat Exchanger etc.) are properly tested and in compliance to equipments required parameters. See to it that proper housekeeping and sanitation are being done by the staff on production lines and equipments. See to it that proper physico-physical chemical analysis is being done on finished product. Well verse on all areas of the Quality Control Section e.g., line testing, microbiology, water treatment, syrup making, GMP audit, trouble shooting and total quality management. See to it that wastewater treatment facility is properly maintained to ensure government compliance. Ensure that water as one of the main ingredients is properly treated and conforms to Pepsi Cola standards. Ensure that water quality, CO2 quality, syrup quality are always within specification mandated by Pepsi Cola International prior to usage. PLANT CHEMIST / MICROBIOLOGIST (April 1991- December 1993) Pepsi Cola Products Philippines Inc., Iloilo Plant San Jose, San Miguel, Iloilo, Philippines Duties and Responsibilities: Ensure Quality Control Policies had been properly implemented. Control proper manning within shift. Coordinate with Production Department with regards to production schedule. Reports to Quality Control Manager on QC activities and status. Ensure that proper housekeeping is always maintained at all times within the laboratory and in the production line. Conducts Microbiological Tests on finished products, bottling equipments and raw materials (e.g. raw water, treated water, empty bottles and refined sugar). Prepare laboratory samples for Central Laboratory in Japan. Prepare daily, weekly and monthly reports for QC Lab. Assist QCM on yearly budget plan. Ensure that instruments and gauges used in the analysis and production operations are properly calibrated and maintained periodically. See to it that proper housekeeping and sanitation are being done by the staff on production lines and equipments. See to it that proper physico chemical analysis is being done on finished product. Ensure that raw materials had been properly check and accepted prior to usage. Well verse on all areas of the Quality Control Section e.g., line testing, microbiology, water treatment, syrup making, GMP audit, trouble shooting and total quality management. Relieve Line Chemists, Syrup Compounders, and Water Treatment Operators in case of emergencies. Ensure that water quality, CO2 quality, syrup quality are always within specification mandated by Pepsi Cola International. Designated as Pollution Control Officer of the Plant. QUALITY CONTROL LABORATORY ASSISTANT (December 1989 – May 1990) Coca Cola Bottlers Philippines Inc., Iloilo Plant Ungka, Pavia, Iloilo, Philippines Duties and Responsibilities: Check and analyze water quality used in bottling operations. Monitor influent and effluent of Waste Water Treatment and recommends necessary action if out of environmental compliance. Check bottling parameters (bottle washer temperature, caustic soda strength, proportioner temperature, caustic soda carryover and empty bottle inspection system efficiency). Conduct Microbiological Tests on finished products, bottling equipments and raw materials (e.g. raw water, treated water, empty bottles and refined sugar). Maintain QC Lab in proper housekeeping at all times. EDUCATION Earned Academic Units for Master of Arts in Chemistry – (2005 – 2006/ 2007 - 2008) West Visayas State University Lapaz, Iloilo City, Philippines Bachelor of Science in Chemistry – (1986 – 1989) Most Outstanding Graduate University of San Agustin Iloilo City, Philippines Bachelor of Science in Chemistry – (1985 – 1986) University of Iloilo Iloilo City, Philippines High School – (1981 – 1985) Graduated 3rd Honorable Mention University of Iloilo Iloilo City, Philippines Elementary – (1975 – 1981) Graduated with Honors Barroc Elementary School Tigbauan, Iloilo, Philippines REFERENCES 1. Paul Brown Farm Manager Almarai Company. Al Nakheel Dairy Farm Riyadh, KSA 2. Kevin Wonnacott Quality Assurance Manager Farming Division Almarai Company. Riyadh, KSA +966 504117311 ALMARAI COMPANY AL NAKHEEL DAIRY FARM INDIVIDUAL TRAINING RECORD Name Position From JOSE JEFFREY WAYNE MAYBAY QUALITY INSPECTOR To Staff No. Nationality Venue 77669 FILIPINO Start Date Location 15 AUGUST 2009 QUALITY ASSURANCE Training Instructor 8/17/2009 8/17/2009 Al Nakheel GENERAL INDUCTION A. Fernando 11/7/2009 11/7/2009 AL NAKHEEL RISK ASSESSMENT TRAINING MR. JAYASIRI 1/9/2010 1/9/2010 AL NAKHEEL FIRE RISK ASSESSMENT TRAINING MR. JAYASIRI 1/9/2010 1/9/2010 AL NAKHEEL PTW TRAINING MR. JAYASIRI 1/19/2010 1/19/2010 GURNATHA SITE ACCIDENT INVESTIGATION MR. JAYASIRI 1/26/2010 1/26/2010 GURNATHA SITE COSHH ASSESSMENT TRAINING MR. JAYASIRI 2/9/2010 PRACTICALS ON CRITICAL CONTROL POINTS -DAIRY PLANT K. WONNACOTT 2/17/2010 2/18/2010 CPP 1 FIRE FIGHTING TRAINING MR. LAKHSMAN 2/17/2010 2/18/2010 CPP FUNDAMENTALS OF FIRE FIGHTING TRAINING3 MR. LAKSMAN 3/9/2010 FMD AWARENESS DR. MOFFED 3/13/2010 3/17/2010 GURNATHA SITE SUPERVISORY SKILLS TRAINING CEDAR ASSOCIATES 4/8/2010 DHMS SYSTEM TRAINING MASKOOR ALI KHAN 4/18/2010 4/18/2010 ANIMAL HEALTH LAB RAW MILK QUALITY TESTING TRAINING DR. SURESH / DR. MATTHEWS 5/12/2010 5/12/2010 AL NAKHEEL COLOSTRUM MONITORING PROGRAM DR. M. REDWOOD 5/16/2010 5/16/2010 AL NAKHEEL EMS AWARENESS TRAINING KEVIN WONNACOTT 5/18/2010 5/18/2010 AL NAKHEEL VOLVO LOADER OPRATIONS MONITOR P.O'REGAN 5/22/2010 5/22/2010 AL NAKHEEL FIRST AID TRAINING COURSE SAUDI RED CRESCENT 6/9/2010 FORKLIFT TRAINING ALI MAHBOOB 7/19/2010 7/21/2010 GURNATHA SITE SUPERVISORY SKILLS TRAINING LINDSAY-CEDAR ASSOCIATES MERCURE HOTEL, 7/27/2010 7/28/2010 RIYADH MISSION, VISION, VALUES TRAINING DR. BRENDAN McCANN - MERCER 8/17/2010 8/17/2010 GURNATHA FOOD SAFETY STANDARD TRAINING KEVIN W. / J. GNANARATNE 10/20/2010 10/23/2010 GURNATHA SUPERVISORY SKILLS TRAINING CEDAR ASSOCIATES - ALISTAIR GIBBS 11/3/2010 11/3/2010 AL NAKHEEL SAFE ANIMAL HANDLING TRAINING ADEL SOLIMAN 11/17/2010 11/17/2010 AL NAKHEEL CONST'N SAFETY/AWARENESS FOR SAFETY INSPECTOR J. GNANARATNE 1/19/2011 1/19/2011 GURNATHA ACCIDENT INVESTIGATION (REFH'R) TRAINING J. GNANARATNE 1/19/2011 1/19/2011 GURNATHA CLASSIFICATION OF NCN & OBSERVATION J. GNANARATNE 1/30/2011 1/30/2011 AL NAKHEEL ALMARAI WORKING SAFELY TRAINING J.GNANARATNE 2/9/2010 3/9/2010 4/8/2010 6/9/2010 AL NAKHEEL AL NAKHEEL AL NAKHEEL AL NAKHEEL From To Venue Training Instructor 1/30/2011 1/30/2011 AL NAKHEEL TOOL BOX TALK - ROOF WORKS J.GNANARATNE 2/16/2011 2/16/2011 AL NAKHEEL ZERO ACCIDENT CULTURE TRAINING J. GNANARATNE 2/27/2011 3/27/2011 GURNATHA OHSAS STANDARD REVIEW K.W. / J.G. 3/22/2011 3/22/2011 AL NAKHEEL INFORMATION SECURITY AWARENESS PROGRAM IQBAL MUHAMMAD - BSD - HO 4/17/2011 4/17/2011 AL NAKHEEL VOLVO LOADER TRAINING (LOADER OPERATIONS) NILS GOSTA NILSSON - VOLVO/MHD. JAVED AKHTAR -A/ R 4/24/2011 4/27/2011 CPP IOSH TRAINING BILL ANDERSON - UK 5/4/2011 VACCINATION SCHEDULE AND VACCINE APPLICATION DR. SCOTT WAIGHT 5/10/2011 5/10/2011 AL NAKHEEL HEIFER CALF REARING PAUL BROWN 5/31/2011 5/31/2011 AL NAKHEEL CALF DISBUDDING TECHNIQUE - ANESTHETIC APPLICATION DR. SCOTT WAIGHT / DR. MOFEED AL KHALIFA 7/13/2011 7/13/2011 AL NAKHEEL PERTMIT TO WORK AND CONFINED SPACES - REFRESHER JAYASIRI GNANARATNE 7/19/2011 7/19/2011 AL NAKHEEL SAFE LOADER OPERATIONS J. GNANARATNE 7/19/2011 7/19/2011 AL NAKHEEL WORKING AT HEIGHT SAFETY JAYASIRI GNANARATNE 9/27/2011 9/27/2011 AL NAKHEEL REFRIGERATION TRAINING (MILK CHILLING) ALLEN RAZON 12/13/2011 12/13/2011 AL NAKHEEL HEALTH AND SAFETY AWARENESS TRAINING PAUL BROWN 3/5/2012 TBT - KITCHEN SAFETY JAYASIRI GNANARATNE 3/12/2012 3/12/2012 AL NAKHEEL HEALTH & SAFETY AWARENESS TRAINING PAUL BROWN/ J. MAYBAY 3/28/2012 3/28/2012 GURNATHA SITE ISO 22000 SYSTEM/ AUDITING AWARENESS JAYASIRI GNANARATNE 3/28/2012 3/28/2012 GURNATHA SITE OHSAS 18001 AWARENESS JAYASIRI GNANARATNE 5/5/2012 FOOD SAFETY AWARENESS TRAINING J. GNANARATNE FIRST AID TRAINING DR. TAYSIR HAYDER - SAUDI RED CRESCENT 5/4/2011 3/5/2012 5/5/2012 AL NAKHEEL AL NAKHEEL AL NAKHEEL 5/26/2012 5/26/2012 AL NAKHEEL