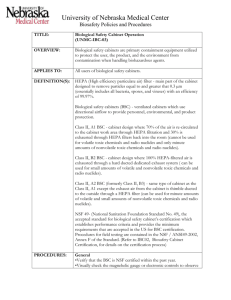

Biological Safety Cabinets

advertisement

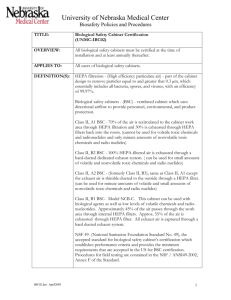

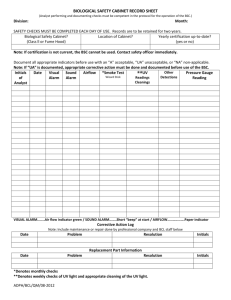

Bloodborne Pathogens • Biological Safety Training • Prepared by: Atef El-Gendy, PhD Bloodborne pathogens • OSHA* Definitions • "Blood" means human blood, human blood components, and products made from human blood. • "Bloodborne pathogens" means pathogenic microorganisms that are present in human blood and can cause disease in humans. These pathogens include, but are not limited to, hepatitis B virus (HBV) and human immunodeficiency virus (HIV). • *(The Occupational Safety and Health Administration) Bloodborne Exposure FAQ How Do I Know if I Have Had a Bloodborne Exposure? • An exposure incident occurs when human blood or other potentially infectious materials enter your body by: • a splash to the eye, mouth, or other mucous membrane • Contamination of non-intact (broken) skin • A puncture or cut with a sharp instrument Which Substances Might Transmit Bloodborne Disease? • Blood or any body fluid or tissue containing blood • amniotic, cerebrospinal, pericardial, peritoneal, pleural, and synovial fluids • semen • vaginal secretions • human organs and unfixed tissues • breast milk Which Substances Do Not Transmit Bloodborne Disease? • • • • • • • • feces nasal secretions sputum sweat tears vomitus urine saliva (very low risk for transmitting Hepatitis, HIV) What Should I Do? • Provide immediate first aid: • go to nearest sink and scrub & bleed puncture or cut wounds • Mechanical scrubbing with soap & water may prevent virus from entering tissues. • Washing eyes with water or normal saline will aid the tears in flushing the virus away. • Mucous membranes of nose & mouth should be flushed with water if exposed to body substances. • Notify your supervisor or employer as soon as possible. Personal Protective Equipment (PPE) • PPE will be chosen based on the anticipated exposure to blood or other potentially infectious materials. The PPE will be considered appropriate only if it does not permit blood or other potentially infectious materials to pass through or reach the employees’ clothing, skin, eyes, mouth, or other mucous membranes under normal conditions of use and for the duration of time, which the protective equipment will be used. Biological Safety Cabinets Types of Biological Safety Cabinets • Biological safety cabinets – Class I – Class II – Class III Class I Biological safety cabinets – Open fronted – Negative-pressure ventilated cabinet – Provides only worker protection NOT product protection Ambient Air Contaminated Air Class II Biological safety cabinets - Negative-pressure ventilated cabinet – Provides HEPA-filtered, recirculated airflow within the cabinet – Exhaust air is HEPA-filtered – Provides personnel and product protection • Types of Class II BSCs – Class II A: HEPA filtered air is discharged into the room – Class II B: HEPA filtered air is discharged out of the room – Class II A/B: Can be used either way. Ambient Air Contaminated Air HEPA Filtered Air Class III BSC 1. Ventilated cabinet - totally enclosed 2. Gas tight construction 3. Operations are conducted through attached rubber gloves. 4. Both supply and exhaust air are HEPA-filtered 5. Provides both personnel and product protection Ambient Air Contaminated Air HEPA Filtered Air HEPA Filter Safe work habits in a Class II BSC – Laboratory coats and latex gloves should always be used – Adjust the stool height so that your face is above the front opening Safe work habits in a Class II BSC – The cabinet blower should be operated at least 3 to 5 minutes before you begin work – Manipulation of materials should be delayed for about 1 minute after placing your hands and arms inside the cabinet – All manipulations should be at least 10 cm from the front grille Safe work habits in a Class II BSC The front and back grilles should not be blocked with equipment, notes, supplies Safe work habits in a Class II BSC • Materials or equipment placed inside the cabinet can disrupt airflow – don’t do this! • Frequent movement of your arms in and out of the cabinet will disrupt the integrity of the air barrier Safe work habits in a Class II BSC Use a smaller biohazard bag in the cabinet Safe work habits in a Class II BSC • Open flames (Bunsen burners) are not allowed in a microbe-free environment of a BSC • Open flames actually creates turbulence that disrupts the air flow Decontamination of BSCs All surfaces should be wiped down with a disinfectant at the end of any procedure • 70% Ethanol (ETOH) is the most commonly used disinfectant • Many people use 0.05% sodium hypochlorite (Clorox or bleach) but remember this is very corrosive to stainless steel, need to wipe off residual bleach with water