Tar sands crude oil requires "aggressive"

advertisement

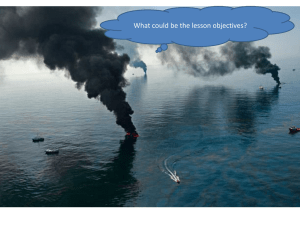

Tar Sands Now Coming to Five SF Bay Area Refineries Tar Sands Crude Oil is aggressively extracted. That is obvious for those who know or care. What is generally not well known, is that Tar Sands Crude Oil must be aggressively refined. Pollution Stress Index – Includes Population Health Vulnerabilities NOTE: REAL WORLD PUBLIC HEALTH IMPACT - High Pollution Stress in Richmond, Pittsburg, Antioch and West Oakland. Furthermore, Pittsburg and Antioch have several large electrical power generating stations. Tar Sands: The Basics • Tar sands, also referred to as oil sands, are a combination of clay, sand, water, and heavy black viscous oil called bitumen. They can be extracted and processed to separate the bitumen, which is upgraded to synthetic crude oil and refined to make asphalt, gasoline, and jet fuel. • Because of its thick consistency (which resembles peanut butter), bitumen, unlike most conventional crude oils, must be diluted with a cocktail of other petroleum compounds before it is able to flow through pumps and tanks or pipelines for transport. This thinner, more fluid product is called diluted bitumen or dilbit. • Over the past decade, this resource which was previously uneconomical due to the high cost of extraction has become profitable as oil prices have increased and extraction technologies have improved. The world's largest known deposits of tar sands are located across three deposits in northern Alberta, Canada. THE BOREAL FORRESTS OF ALBERTA CANADA, HOME TO NATIVE AMERICANS, ARE BEING SCRAPED FOR TAR SANDS CRUDE OIL, 2OO FEET DOWN IN AN AREA THAT WILL APPROACH THE SIZE OF FLORIDA WITHIN A DECADE Photos by Garth Lenz Northern Alberta’s oil (ie “Tar) sands are one of the world’s largest known hydrocarbon deposits, considered second in size to Saudi Arabia Initial Tar Sands Processing begins in Canada, because Tar sands crude is too heavy and thick to flow in pipelines. NOT ALL HYDROCARBONS ARE CREATED EQUAL ! • Pure hydrogen (H2) can be used for liquid rocket fuel and there is absolutely no carbon footprint. • Natural gas (CH4) methane, has one carbon only, surrounded by 4 hydrogen atoms. Natural gas is the ideal hydrocarbon fuel, as it has four hydrogen atoms per carbon and is therefore considered very hydrogen-rich. Yet, it is a nontransportation gaseous fuel, and needs either thick vessels to contain it or pipelines to transport it. • Gasoline, a high-octane hydrocarbon transportation fuel has, within a single straight chain, 8 carbons on average. It is ideal for U.S cars, having 2.25 hydrogen atoms per each carbon, on average and so is less hydrogen-rich than natural gas. Gasoline burns well, but has a large carbon footprint. • Longer-chain hydrocarbons, like olive oil, are more viscous than gasoline and can still burn, as in an ancient olive oil lamp. Axil grease is composed of very long chain hydrocarbons and also does not burn as well as gasoline. • Hydrogen gives lighter hydrocarbons their great energy potential as a fuel. Conversely, with few hydrogen atoms in an oil and many more carbons, its viscosity greatly increases and so it flows more slowly. ASPHALTENE AKA Pitch, Tar, Bitumen. Asphaltenes are the large, high molecular weight, multiple-ringed carbon molecules in the most highly viscous, low-quality crude oils and they have only about one hydrogen per carbon. Because asphaltenes stack and stick together, they can plug pipes, pave roads and tar roofs; they cannot make gasoline or diesel fuel without very aggressive processing. Tar-Like Asphaltene Pipe Plug Heavy Oils have a Large Carbon Footprint • • Table of Fuel Oils Name Alias Carbon Chain Length • • • • • • No. 1 distillate No. 2 distillate No. 3 distillate No. 4 distillate No. 5 residual fuel oil No. 6 residual fuel oil No. 1 diesel fuel No. 2 diesel fuel/Trucks/Home heating oil No. 3 diesel fuel No. 4 residual fuel oil Heavy fuel oil/Ship Bunker Oil Heavy fuel oil/Ship Bunker Oil Distillate Distillate Distillate Distillate/Residual Residual Residual 9-16 10-20 12-70 12-70 20-70 Highly viscous No. 5 and 6 residual fuel oils need to pre-heated to be atomized before burners. • • • • • Burned Fuel Coal Natural Gas Distillate Oil (#2) Residual Oil Lbs. CO2 Per kWH 2.08 -2.18 1.22 * 1.68 1.81 Coal and Residual Oil have large carbon footprints and * unburned Natural Gas (fugitive Methane), a very large carbon footprint. REFINERIES SEPARATE CRUDE AND TRANSFORM HYDROCARBONS Simple Distillation Refineries Produce Less Gasoline and Diesel from Lower Quality/Denser Crude Oils CRUDE OIL CHARACTERISTICS: YIELDS DISTILLATION vs REFINERY OUTPUT TAR SANDS HEAVY CRUDE OIL = DENSE and LIKE CALIFORNIA CRUDE, HARD TO REFINE • Much of California’s current petroleum output is categorized as heavy or extra-heavy oil, meaning it is more viscous and requires more energy and time to refine into fuel than lighter grades of crude. In many ways, it is similar to the thick “bitumen” petroleum that comprises Alberta’s tar sands. • All heavy and extra-heavy grades require a variety of energy-intensive methods to liquefy, extract from the ground, and refine into gasoline, diesel and other transportation fuels. Tar Sands Large GHG Footprint • Tar sands crude oil requires "aggressive" refining in order to break up large molecules and remove sulfur, ie, high-temperature “coking” units and “hydrocracking” units that use massive amounts of hydrogen gas produced on-site. • In order to make into gasoline, Tar sands refining produces 2-to-3 times the greenhouse gasses (Carbon Dioxide, ie, CO2) than when refining typical traditional U.S. crude. The Dirty Hydrogen Economy = Aggressive Crude Oil Refining • The high temperature and very high pressure process called “Methane Steam Reforming” of natural gas (aka methane/CH4) is used to strip off the four hydrogen atoms from methane for use in the refineries hydro-cracking and hydro-treating units. • For “hydro-cracking”, pure hydrogen under great pressure can take a heavy, long-chain hydrocarbon, such as one with 16 carbons and split it into two 8-carbon chain hydrocarbons, such as highly valued, high octane gasoline. • For “hydro-desulfidation”, hydrogen can also remove sulfur from gasoline, diesel and jet fuel. Low Quality Crudes Need Aggressive Processing ) IMPORTANT: Aggressive processing adds hydrogen to split or crack very large hydrocarbons, aka hydrocracking and also to remove carbon, by high temperature coking from “bottom-of-the-barrel” heavy residual oils, producing a solid carbon-rich product. Massive Refinery Emissions Increaserefinery if 95% confidence of prediction for average CO2 Switchedfrom to Tar Sands Bitumen Crude oils emissions a complete switch to low–quality (a) US avg. 1999–20081 (b) California avg. 2004–20092 (c) Shell Martinez 20082 (d) Prediction for switch to average heavy oil1 (e) Prediction for switch to average tar sands bitumen1 WWW.CBECAL.ORG 42 Coker Units for processing cheaper “Bottom-of-the-Barrel” Crude Oil Petroleum Coke, AKA PetCoke, is the coal-like residuum at the bottom of the coker unit, that is mostly too dirty to be burned in the U.S. and so is shipped to China and India for power, steel and cement plants. Cokers remove carbon as PetCoke residue. A Coker Unit refines the “Bottom-of-the Barrel” low-quality crude at very high temperature, ie, 500 degrees C. Coking defines aggressive processing and activates sulfur corrosion… 2012 RICHMOND (CA) REFINERY FIRE August 3rd, 15,000 people went to the ER ISAIAH 34.9: And the streams of [Edom] shall be turned into pitch, and the dust thereof into brimstone, and the land thereof shall become burning pitch. Pollution Stress Index – Includes Population Health Vulnerabilities NOTE: REAL WORLD PUBLIC HEALTH IMPACT - High Pollution Stress in Richmond, Pittsburg, Antioch and West Oakland. Furthermore, Pittsburg and Antioch have several large electrical power generating stations. The Dirty Hydrogen Economy = Aggressive Crude Oil Refining • The Richmond Chevron Hydrogen Renewal Project would complete construction and make operational the Hydrogen Plant Replacement and Hydrogen Purity (sulfur removal) Improvement of the Original Project. • Air Products Local Area Pipeline Network Project: Air Products and Chemicals Inc. (Air Products) owns and operates a hydrogen plant located within the Shell Martinez Refinery. • Praxair Contra Costa Pipeline Project: proposed to develop an approximately 21.3-mile hydrogen pipeline from the Chevron Richmond Refinery to the Shell Martinez Refinery. This pipeline would include a 1.1-mile lateral pipeline extension to the ConocoPhillips (now called Phillips 66) Refinery in Rodeo, California. Hydrogen pipeline and related project blocked by lawsuit from Communities for a Better Environment, CBE. Conoco-Phillips Rodeo Refinery • ConocoPhillips Canada has a leading land position in Alberta’s Tar (ie. Oil) Sands. • Greg Maxwell, Phillips 66 executive vice president of finance and CFO noted that they are the “largest importer of Canadian crudes [ie, Tar Sands] into the United States”. • Maxwell also announced the addition of 2000 new railroad tanker cars to bring financially advantaged (inexpensive, low quality) crudes to their domestic refineries and they increased their socalled advantage crude runs at their refineries in 2011 from 52% to 68% in the first quarter 2013, further stating: “ our plan to be able to run 100% advantaged crudes within the next few years”. Phillips 66 Local Tar Sands Expansion Projects • Phillips 66’s so-called “clean fuels expansion project” (CFEP), now completed, was designed to make 35 percent more gasoline and 21.5 percent more diesel and jet fuel from a vastly increased input of lower quality crude oil feedstock. • Phillips 66 proposed “Propane Expansion Project”, will switch refinery operations to currently inexpensive natural gas, and recover the propane, formerly used as a refinery fuel gas (to operate refinery), for sale. • After the propane recovery project completion, Phillips 66 refinery total output will increase another 11.4 percent. • NOTE: Increased propane production requires an expansion of coking, that produces 3 times more propane than less aggressive crude distillation and essentially “locks” refinery production into lower quality feedstock, such as Tar Sands. Refineries’ Collateral Damage • Each of the refineries’ massive increase, in natural gas usage, hydrogen production and overall energy usage required for refining Tar Sands also locks-in the refineries’ use of frequently fracked natural gas, further compounding environmental degradation. Fracking for NG also releases massive amounts of fugitive methane, a GHG 20-50 times more powerful a GHG than CO2. • Phillips 66’s propane project will require six large pressurized 2,500 barrels (42 gallons per barrel) to store propane and will be placed within a liquifaction/seismic zone. Liquid propane is to be transported to market by railroad tanker cars through numerous communities. • CBE is representing the Rodeo-Crocket communities in challenging the propane project. One of the dangers of pressurized propane storage is Boiling Liquid Evaporative Vapor Explosion or BLEVE. • Local schools and homes would be within the blast radius of these pressurized propane tanks. Wall Street Mega-Bank Behind TransCanada KXL Pipeline • The Wall Street Mega-Bank, Citigroup, raised more than $5.8 billion for TransCanada Pipeline development to deliver Canadian Tar Sands crude to United States refineries. • Michael Froman, former CITI CEO and General Manager, is now the top U.S. Trade Official. He is lobbying aggressively for the European Union to accept U.S. Tar Sands Oil products over EU objections. • Tar Sands products are currently prohibited by EU law that places a limit on the import of high carbon-footprint diesel fuel from low-quality crudes, like Tar Sands crude. • AN ADDITIONAL LOCAL AND REGIONAL CONCERN: There are currently plans for a TransCanada Alberta-California pipeline. Note Proposed TransCanada Pipeline to CA Tar Sands Crude Oil Shipped to CA Refineries Benicia Valero Tar Sands-by-Rail Project PHASE 1: VALERO IMPROVEMENT PROJECT (Completed): • “Provide ability to process lower grades of raw materials” (Need more hydogen) • “Construction of the proposed Air Liquide Hydrogen Pipeline or Air Products Hydrogen Pipeline” • Optimize operations for efficient production of clean burning fuels. (Need more hydrogen to remove sulfur and make more gasoline) REMEMBER: More refinery hydrogen production requires more local energy production and natural gas input. Moreover, Coking requires a massive amount of heat (~500 degrees C/900 degrees F), that yields more GHG production than tradition crude oil distillation. PHASE 2: The proposed Benicia Valero Crude-by-Rail Project (not mentioned in Phase 1 EIR). Aggressive Refining in the Bay Area Valero stated: “If heavy crude oil prices are not discounted as expected, less heavy crude will be purchased and some of the Coker Expansion facilities may be deferred”. TRANSLATION: They want inexpensive crude, that by nature, is low quality and requires coking. WesPac Petroleum Storage Depot • PROPOSED: PITTSBURG WesPac Energy Infrastructure Project (aka Petroleum Tank Storage Depot) will have a 242,000 Barrel per day throughput by railroad and marine tankers, that is over 25 percent of Bay Area refining capacity. • CRUDE INPUT is by railroad tank cars and ship. OUTPUT is by 42 mile long Pipeline to all four Contra Costa refineries and ending at the Richmond Chevron refinery. • THE WesPac Depot Project will critically enable the massively increased delivery to the Bay Area of Canadian Tar Sands crude and the local refining of this outrageously low-quality crude. • Like refineries, the WesPac Depot would be adjacent to low income and minority communities, schools and churches. Our Concerns over Tar Sands • CONCERNS: Local, Regional and Global. • CONCERNS: Environmental Justice (local, ie, poor, minorities and indigenous communities) “OR” Climate Change (regional and global). • Are local versus global environmental concerns “either/or” issues Opposing Tar Sands Exploitation • What way can Tar Sands stopped being extracted? • What way can Tar Sands stopped being refined locally? • Tar Sands crude must first be transported to refineries. What can be done? • REMEMBER: Refineries typically require “upgrading” projects to be able to refine high-sulfur Tar Sands crude, particularly expansion of hydrogen production and more high-temperature coker units. • What types of action can we locally bring to play to stop Tar Sands from becoming crude oil products? 1) Local political constituency objections to projects’ EIRs (local communities frequently need technical help from environmental non-profit scientists, ie CBE and NRDC). 2) Electoral pressure on elected politicians, particularly Democrats. 3) Protests, in streets and in meetings. 4) Non-Violent Civil Disobedience. No Tar Sands Crude Extraction!!! No Dirty Energy !!! BAY AREA AIR QUALITY MANAGEMENT DISTRICT RESOLUTION Currently proposed 350 Bay Area Resolution to lead the Development of a Regional Greenhouse Gas Emission Reduction Plan WHEREAS, total Bay Area GHG emissions exceed those of many developed countries, such as Portugal, Ireland, Israel, Denmark, and Sweden; and WHEREAS, [consistent with the Executive Order S-3-05, signed by Governor Schwarzenegger and reaffirmed by Governor Brown,] the Bay Area Air Quality Management District's 2010 Clean Air Plan set performance objectives to “Reduce emissions of greenhouse gases (GHGs) to 1990 levels by 2020 and 40% below 1990 levels by 2035”; and WHEREAS, the counties of San Francisco, San Mateo and Santa Clara have already endorsed the [executive] orders’ 2050 goal as stated above; WHEREAS, the federal Clean Air Act and California Health & Safety Code §39002 establish that the BAAQMD has primary authority to regulate nonvehicular [i.e., stationary, e.g., petroleum refineries] sources of air pollution, including GHGs, and to enact more stringent requirements than federal or State law; Development of a Regional Greenhouse Gas Emission Reduction Plan (Cont.) Therefore: The Regional Greenhouse Gas Emission Reduction Plan builds on its existing Climate Protection Program to include the following emission reduction strategies for non-vehicular sources: • Deep energy efficiency improvements, • Decarbonization of regional electricity supply, and • Increased electrification of existing fossil fuel uses; and to include the following Program Elements: • A scoping document to identify GHG emissions for which the District (BAAQMD) is the primary regulatory authority, • An Enhanced Regional GHG Emission Inventory and periodic updates to forecast emissions and document the effectiveness of regional, state and federal GHG emission reduction efforts, The Photo-Voltaic Electrical Generation Surge: The national average price of an installed PV system declined by 26.6 percent in 2012 and about 75 percent since 2008. Two-thirds of all distributed solar PV capacity in the U.S. has been deployed in the last 2 1/2 years. $ Decreased Cost of Electric Car Batteries: 2008-2012 $ The Dept. of Energy (DOE) reports that the cost of manufacturing an EV (Electric Vehicle) battery has dropped by 50 percent since 2008. Deployment and Cost of U.S. Land-Based Wind Power 1980 1990 2000 2010 The cost of electricity from wind has fallen to around 5 cents per kilowatt-hour -a 90 percent drop since the 1980s. In 2012, wind was the single largest source of new electricity capacity in the U.S., beating even natural gas. For our Children and the Planet… • Sunflower Coalition 2013 - 8:3 “…and their righteous indignation shall be raised to a burning pitch.”