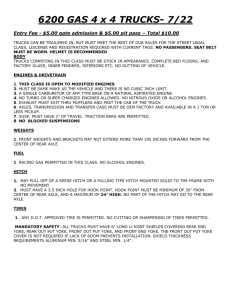

2016 rules packet diesel & gas pick-ups

advertisement

2016 Gas, Diesel, Semi, & 466/540 Tractor SLED PULLING RULES General Rules 1. Any contestant under 18 must have written consent from parent or guardian and prior approval from Promoter/ Track Official or Safety Committee. Minimum age for competition is 16 years old. 2. Contestant may not be allowed to participate due to emotional or physical reasons. (i.e. including drinking or illness, etc.) 3. Only driver will be allowed in vehicle when it is being towed or driven. 4. Driver must be in driver’s seat while engine is running while on Track. 5. Vehicle must be in neutral or park while hooking to or unhooking from sled. Driver must also raise hands while hooking or unhooking from sled. Track Official, Promoter, Sled Operator can refuse to hook any vehicle / driver for any reason that may / could cause harm to: event, track personnel, equipment, spectators, etc. 6. Any driver or crew member found under the influence of drugs or using intoxicating agents on the property will be disqualified and/or be banned from property for remainder of event. 7. No videotaping is allowed closer than 30 feet from track, unless directed by Promoter or head track official. 1 8. The first puller in the class will have the option of test puller. The test puller may accept their distance, come immediately back or drop five (5) positions in the pulling order. The test puller may drop to last for mechanical breakage, if visible to the finish line track official. The test puller must inform the track official of their decision before leaving the track. 9. Once track is ready and competition director signals competitor to the track, competitor will have four (4) minutes to make a measurable distance under green flag conditions. 10. Puller may spot the sled anywhere in bounds and behind starting line if they wish. This must be done while sled is coming back to the starting line from the previous pull. Only one sled spotting is allowed. 11. All pulls will start with a tight chain. No jerking of sled is permitted. Excessive jerking of the sled will result in disqualification. 12. Excessive loss of liquid will result in disqualification, if vehicle is under the green flag. Failure to stop will result in disqualification. Excessive is defined as any steady or intermittent stream equal to a spot on the track of ten (10) inches in diameter. Major mechanical breakage will not result in disqualification. 13. Pulling will be considered over when forward motion stops. Puller must stop immediately when flagged or be disqualified. 14. Any re-pull caused by contest malfunction, the puller may drop five (5) positions or drop to the end of the class. Puller may not move any weight or competitor will be disqualified. 15. All pulls will be measured to the nearest inch, unless a laser is used. 16. When possible, all contestants must drive off and on the track. Tow starting will be done at last resort and under track judge’s discretion. 17. All pulling vehicles must pass a tech inspection and meet all safety requirements before they can pull at any event. Promoter/Track Official retains the right to inspect any vehicle at any time. Refusal will result in disqualification. 18. No competitor may compete in a class, once the class has started, if arriving late. 19. Boundary line will be 320’ long to start the pull, even though a Full Pull may only be 300’. Competitor may not touch boundary lines at any time. The Full Pull line will be established by the Head Track Official no less than 300 feet and no later than the fifth competitor, after a sled reset. The Full Pull line can be set in front of a vehicle even if vehicle has gone past 300 feet at either 310 or a maximum of 320 feet, White disqualification line(s) will be 320 feet for entire contest. If Promoter/ Head Track Official determines a floating finish is needed that will be decided by the fifth competitor as well. 20. While vehicle is at scales weighing, only one crewperson allowed in scale-master’s area. 21. Judges decisions are final. There is no appeal process. Disagreement will result in disqualification. 22. Once in Staged area NO Smoking & No Cell Phones till After Your Hook and parked in pit Area. 23. Each competitor will be allowed 2 attempts to make a measurable pull, an attempt is defined as moving the sled a Measurable distance (1 inch or farther), on first attempt, if competitor lets off throttle before 100 ft. said competitor will get a second attempt, even if the vehicle travels beyond 100 feet. 2 Additional Safety and General Rules 1. Fire suits recommended for all classes but are required in all classes stated ( Fireproof gloves, fireproof head-sock, and fireproof shoes must meet SFI Spec. 3.3. All helmets must meet Snell 90 minimum, or SFI Spec. 31.1, 31.2, 41.1,or 41.2. D) Neck collars are recommended. 2. All pulling vehicles are required to have a minimum of 2.5 lb. fire extinguishers which are fully charged. Extinguishers must be within reach of driver. 3. Seatbelts must require 16.1 SFI Spec on all driver restraint assemblies and be worn during competition. 4. All vehicles will have a safety switch. The safety switch will ground the ignition and the electric fuel pumps on spark ignition motors and shut off the air intake to diesel motors. 5. No batteries are allowed inside cab of the vehicle unless they are in a marine battery box and secured to the vehicle frame. 6. All pulling vehicles will have a dead man throttle that will automatically return to the closed position. Throttles will work in a reverse to forward motion, reverse being closed. 7. All pulling vehicles must have a starter interrupter switch that will allow starter engagement only in neutral or park position on a transmission gear selector for mechanical reasons during the season. 8. All vehicles using an automatic transmission must have a positive gear lockout. 9. Drivers or crewpersons must be seated and in control of the pulling vehicle any time motor is started or running. 10. For all pulling vehicles that require a neutral safety light. A) A white light automotive quality, a minimum of 2 inches in diameter, must be mounted within 30 inches of hooking point. And within 6 inches of center line, B) A light in the driver’s compartment must be operated off the same system. C) Both lights and the starter interrupter switch will be operated off of the shifter lever. D) A neutral light should illuminate when vehicle is in the neutral position. Lens color should be clear. 11. Promoter/Track Official reserves the right to refuse any competitor the right to attend or participate at any event. Pull-Offs 1. Each competitor will have two (2) attempts to make a measurable pull. 2. In a pull-off each puller will hook in the order that they pulled in original class lineup. No dropping of positions is allowed in a pull-off. 3. If the track official believes that an error has occurred in sled setting, pull-off may be restarted. In this case, the first puller may come right back or drop to last. 4. In a pull-off, a floating finish line will be used for all competitors. 3 SLED PULLING RULES/REGULATIONS Stock Gas Class 1. Eligible to all year trucks. 2. Weight class maximum 6800 lbs. 3. D.O.T stamped approved street tires only. No cuts, grooved, bar, or tractor type tread. No sharpening. Rim width cannot exceed MFG specified tire width max tire size 33x12.50. Max track width is 102” 4. Must have Full body, Full interior, working street equipment (lights, mirrors) 5. Must be 1 ton stock or smaller factory frame, 1 ton or smaller axles only. 6. Must have 4 wheel brakes. 7. Pump gas only, No accelerators permitted, ex: propane, nitrous, etc. No forced induction, ex: blower, supercharger, turbo, single carb, throttle body. No multi induction other than factory multiport injection. 8. Drivetrain must match year, make and model as to what was offered in vehicle from the factory at that Time, ex: engine, trans. 9. Drive shaft loops and U-joint scatter shields highly recommended. 10. Engine must be consistent with year, make and model. Factory engine blocks only. Cast iron heads only. Must be factory heads. Engine must be stock appearing and sounding. No cams, no lumpy idle. No vacuum pumps. 11. Intake may be changed / updated. Any make but must be dual plane for carbed vehicles. Standard height intake, no tunnel, rams or excessive spacers. Adapter plates permitted for carb update. Carb updates acceptable ex: Carter, Holley, etc. 12. No 4500 (dominator) or exotic carbs allowed. No internal engine modifications allowed. 13. Ignition factory and factory replacement only. No CDI allowed (MSD, Mallory, etc.) or magnetos. 14. Exhaust must exit under vehicle and behind cab. Muffler not needed but pipes must exit behind cab. 15. Added weight permitted but must be secured in the bed. No hidden weight, No weights allowed in the cab, No front weights or weight boxes allowed. 16. 26 inch hitch height hitch must be a Reese style hitch. Can be fabricated but must accept a receiver insert to pull off of. Hitch can be mounted within frame rails but not on top or above frame. Hitch is to be bolted to the frame and rigid in all 4 directions. May be reinforced but no reinforcements may be further forward than rear axle center line. No drawbar hitch whatsoever. Hook point must be rearmost point of truck. Hook point cannot be under body of the truck. Hook point must be parallel with frame rails and hitch. 17. Snowplow frames and brush guards are allowed, No homemade bumpers, brackets or weight boxes allowed in this class. Must have stock appearing front bumper and rear bumper. 18. ABC fire extinguisher (minimum 2 ½ lbs) must be in cab within drivers reach while seated in vehicle to pull. 19. Seatbelt required, Helmet recommended. 20. Must be factory suspension. Must be live front suspension ex. (no front bump stops) . No traction bars. No rear bump stops allowed. No trussing of frame. No strapping, chaining or cabling is permitted. If equipped with airbag suspension helpers, system must be empty. This will be checked. Hot Street Gas Class 1. Eligible to all year trucks. 502 Cubic inch Limit 2. Weight Class maximum 6800lbs trucks 3. D.O.T. stamped approved street tires only. No cuts, grooved, bar, or tractor type tread. No sharpening. Rim width cannot exceed MFG specified tire width. 35x12.50 max tire. Max track width is 102” 4. Full bed floor and sides are permitted, Flat bed or homemade bed allowed, but must cover tires and be stock length. Metal aftermarket hoods are permitted. Fiberglass frontend/hoods are permitted. 5. The hood must be closed and securely latched while vehicle is hooked to sled. The complete OEM firewall and OEM floor pan is mandatory. 6. Pump gas or race fuel ONLY. No alcohol, nitro or nitrous. If nitrous equipped, bottle must be removed and lines unhooked. 7. Engine must be naturally aspirated. No supercharger or turbocharger allowed or blower, No sheet metal intake manifolds allowed. One single four barrel carburetor (or smaller). Air cleaner is required. Factory fuel injection or throttle body system allowed. 8. No weights allowed in the cab, No weight boxes allowed or front hanging weights. Weights may be fastened behind the bumper . Push tubes are allowed must be factory appearing may only have single loop. Push tube must not be larger then 4 inch OD. Any added weight on the front end must be hidden. All added weight must be securely attached to the vehicle. Front bumper must in factory location. 9. Hitch must be a Reese style hitch. Can be fabricated but must accept a receiver insert to pull off of. Hitch can be mounted within frame rails but not on top or above frame. Hitch is to be bolted to the frame and rigid in all directions. May be reinforced but no reinforcements may be further forward than rear axle center line. No drawbar hitch whatsoever. Hook point must be rearmost point of truck. Hook point cannot be under body of the truck. Hook point must be parallel with frame rails and hitch. 10. The hitch / hook point must be in place at scale weigh-in. Clevises permitted but must accept hook vertically only. 11. Must have full interior and all glass, and all street equipment ex. Lights and mirrors, must have reverse lights 5 12. Open exhaust permitted, must exit behind cab. 13. Drive shaft loops and rear cans are required. 14. ABC fire extinguisher (minimum 2 1/2 lbs.) must be in cab, within driver's reach. 15. Seat Belt Required, Full factory seatbelt or minimum 2 point race harness. Helmet Required, Helmet must be strapped, neck brace recommend. 16. Suspension: Front: The upper mounting point for strut assemblies must be in factory location, Adjustable caster / camber pillow ball mounts are permitted, The lower control arm may be strengthened as long as factory mounting points to chassis are maintained, The lower mounting point for strut assembly may be modified for improved caster or camber, Strut tower braces, lower tie bars and sway bars are permitted, Traction bars and devices are permitted 17. Suspension: Rear: An OEM Style suspension is mandatory, Lowering or raising the vehicle height with suspension modifications is permitted. Traction bars and devices are permitted. They must be Bolt-on only; welds are permitted for attachment to frame or axle housing. All OEM suspension mounting points must be retained and used; Sway bars and camber kits are permitted. The rear suspension must maintain a minimum compression shock travel of one inch compression. Stops may be adjustable. All rear suspensions must use at least one working shock absorber per wheel. If equipped with airbag system. System must be empty and any in cab controls or compressors must be made inoperable or removed. Mod Gas Class 1. Weight Class 6800 lbs. 158’’wheelbase. 2. Truck body must be complete with hood, doors, and bed, the bed must have the floor in place or a top cover in place, No fiberglass bodies allowed. Must have windshield and rear window. Must have working brake light or neutral safety light, Automatics must be put in park when being hooked up to the sled at start line 3. Weight box or weight bracket allowed to be 193" from the center of the rear axle to the front of weight, Weights cannot be more than 60" from the center of the front axle, Weights in the bed must be secured, No weights are allowed in the cab. 4. Any DOT approved tire allowed. Wheels may not be wider than tire width. Example: 14" wide tire on a 14" wide wheel, Rim width cannot exceed MFG specified tire width, NO Tire sharpening allowed, No cut, grooved bar tread, or tractor type tires allowed. 5. Pump gas or racing fuel allowed. No Alcohol, Nitro or Nitrous allowed. In the event a truck is equipped with a Nitrous system, the NOS Bottle must be removed and lines unhooked in order to compete. 6. Open headers allowed, upright headers allowed. Vertically discharging must be within 10 degrees of plumb. Downward header exhausts must discharge under the truck to the rear, No side or downward discharge of exhaust is allowed. 7. Any intake manifold and single carburetor combination allowed, Single carburetor may be any size, Engine must be naturally aspirated, No supercharger or turbocharger allowed, No sheet metal intake manifolds allowed 8. Kill switch or breakaway switch required within 24” of hitch point, All kill switches will be tested at the scale for proper operation, Kill switch must kill the engine and any electric fuel pumps, A tie strap will be used to during tech inspection to show vehicle kill switch has been inspected, A 1/4" diameter hole will be used to securely hold the tie strap just above the kill switch, Only if tie strap is broken, decided by head track official, will competitor be given opportunity to pull again. 6 9. Standard transmissions must have a steel flywheel and a blow proof bell housing or S.F.I. blanket, Automatic transmissions must have an S.F.I. blanket / shield. 10. Drive Shaft loops for the front and rear drive shafts and U-joint shields are required, All U-joints must be shielded 360 degrees with 3/8 aluminum or 5/16 steel, All shields must be 6” long minimum and must be centered over the U-joints, The inside of the shield must not be more than 2” larger than the U-joint, Each truck must have 1 loop for the front drive shaft and 3 loops for the rear drive shaft. 11. All drive line components must be for 4X4 vehicles, 1 ton and underweight rating, No drop boxes or reversers. 12. Maximum hitch height allowed is 26” from the top of the hitch to level ground. (Hitch can be lower). Hitch must be a receiver type towing hitch or a special constructed pulling hitch. No bumper hitches, Hitch must be rigid in all directions with a minimum of a 3 inches wide by 3 3/4 long inside opening, No vertical hitch or openings from point of hook to centerline of rear axle shall be no less than 30% of truck wheelbase and shall not slope any greater than 33 degrees to hitch point, No hitch supports or adjusters, if fastened to the rear housing shall be above the centerline of rear axle, Pivot pin of drawbar can be no farther forward than the center line of the rear axle. 13. OEM suspension can be blocked solid non rigid ex: suspension must have upward travel; any blocked suspension must be safely fabricated and securely fastened to the frame as determined by the tech inspector. Must be welded or bolted to the frame with no less than two bolts ½” or greater grade 8. 14. Each truck is required to have an ABC fire extinguisher in the cab and within reach of the driver, Extinguisher must be a minimum of 2 ½ lbs., Must be secure in the cab within drivers reach while seated in vehicle as to pull. 15. Driver must wear a seat belt, fire suit (jacket & pants) and helmet. Helmet must be strapped, Driver must wear leather boots or SFI type fireproof shoes while pulling, Seatbelt can be factory 2 or 3 point but 4 or 5 point seatbelt is recommended. 16. Truck must have operating front brakes 17. Truck must have sled stops. 18. Truck must have a fan shroud, Radiator must be ahead of the motor between the grill and the engine 19. A fuel cell may be used. 20. Axle shields are required, Shield to be .060" thickness steel or aluminum, Shield not to be mounted to axle ends or hub bolts. A single hole may be cut in one to allow locking of hubs 21. Frames must be OEM style...No tube frame… no trussing of frame, Must be 1 ton or smaller frame front to rear 22. Modifications to frame is allowance of pulling hitch construction and welding of traction bar mounts 23. Max track width is 102” Pro Mod Gas Class 1. Maximum weight of pulling vehicle is 6,800lbs. 158’’ Wheelbase. One Vehicle Brake Required, Fire Suit Required 2. No cubic inch limit. 7 3. Any automotive type engine, must be naturally aspirated, with only two valves per cylinder and must accept a stock automotive crankshaft. 4. No accelerators permitted and no forced induction ex: Nitrous, Nitro Methane, Propane, Blowers, Turbo, Superchargers 5. Race fuel accepted 6. No fuel tanks, fuel lines, pressure gauges or pumps allowed in cabs. All hydraulic lines in cab must be shielded top and sides with a minimum of .060 aluminum. 7. Truck or van bodies permitted and must have complete firewall 8. Must have a windshield. Clear plexiglass or factory tint glass permitted 9. Must have minimum 4 point seatbelt harness 10. May be blocked or welded solid. Must be done in a solid and safe structural manner as to no parts can easily fall off. 11. Any blocks installed in suspension must be welded or bolted to frame with no less than two bolts ½” or greater and grade 8 12. Tube frames and ridged rear suspensions are permitted. 13. No mud flaps or dirt deflectors will be permitted. 14. Hitch height maximum is to be 26" at point of hook before, during, & after pull. Hitch must be rigid in all directions mounted solid. Minimum hitch opening to be 3 inches wide by 3-3/4 inches long inside opening. Pulling point can be no more than 1.5" from back edge of drawbar. No clevis, chains, or cables permitted in hitching device. From point of hook to centerline of rear axle shall be no less than 30% of truck wheelbase & shall not slope any greater than 25 degrees to hitch point. Secondary safety hitch below pulling hitch required and must be integrated with pulling hitch and frame. 15. No hitch supports or adjusters, if fastened to the rear axle housing, shall be above the center line of the rear axle. Pivot pin of drawbar can be no farther forward than centerline of the rear axle 16. Weight box or weight bracket allowed to be 193" from the center of the rear axle to the front of weight, Weights cannot be more than 60" from the center of the front axle, weights in the bed must be secured, No weights are allowed in the cab. 17. Any dot allowed tread may cut. Max tread width 16.50 inches Rim width cannot exceed MFG specified tire width. Max track width is 102” 18. Axle shields are required. Shield to be .060” thickness steel or aluminum. Shield not to be mounted to axle ends or hub bolts. A single hole may be cut in one to allow locking in of hubs. 19. The use of hydraulic cylinders to retract or extend the position of a weight box is permitted IF: A).The cylinders themselves internally limit the travel within the allowable 60". B). During tech it will be pinned at exact position & must stay in that position during weigh-in, hitch pad adjustment & competition. 20. Must follow all the general safety rules mententioned above. 8 Street Stock Diesel 1. Driver must have a valid state issued Driver’s License. Vehicle must be street legal, have current state inspection sticker and license plate, NO DEALER TAGS. Vehicle must be in the same physical condition as at the time it was inspected for current highway use. Registration card and license plate must match. 2. Engine must be compression ignition engine factory produced for 1 ton or smaller diesel pick-up trucks. Engine swaps between manufacturers is prohibited. Must run Oem intake manifold. Aftermarket programmers and chips allowed. Aftermarket air to air intercoolers are allowed. 3. Turbochargers must be in original location and must be an unmodified stock OEM turbo. No billet wheels, or any modifications will be allowed to the turbos. 4. Maximum Truck weight including driver is 8,500lbs. Added weights must be mounted and secured in bed of truck. No weights allowed in the truck cab. Front mounted weights are not allowed, front bumpers must be O.E.M., lower brackets for snow plow frames are permitted, and no modifications that add weight are permitted ( No hidden weights under the truck) 5. No aftermarket heavy front bumpers permitted. 6. Fuel must be #1/#2 diesel fuel only. Soy/Biodiesel fuel is permitted. No other combustible material (nitrous, propane, etc) may be injected into turbocharger or any part of air intake system. Water injection is not permitted. All nitrous, propane and water injection systems must be removed from vehicle. 7. The fuel injection pump is limited to a stock appearing OEM. pump no dual pumps allowed. 8. All vehicles must have 4-wheel hydraulic brake system in good working condition. 9. Headlights cannot be removed for air duct lines.. 10. Hitch must be a “Reese” style hitch. Reinforcements are permitted but are not allowed forward of the centerline of the rear axle. The hooking point must be the rear-most point on the vehicle. Hitch point cannot exceed 26 inches in height before, during or after the pull. Hitch must be horizontal to the ground and stationary in all directions. The hooking point must have a minimum 3.00 inch wide x 3-3/4 inch opening for the sled hook. NO “Trick” hitches will be allowed. Hitch must be bolted to bottom of the frame only. No draw bars allowed. 11. Vehicles must have OEM firewall and floor. Only holes allowed are those for brakes, clutch, transmission controls and wiring. 12. Wheels and tires must have dot. Approved number on sidewall. No cutting, grooving, shaping or sharpening of tire tread is permitted. No studded tires or chains allowed. On factory dual wheeled trucks only a 10 inch tire tread maximum width per tire and 33 inches tall. 33 x12.50 tires maximum on single wheel trucks. No dual wheels allowed on factory single wheeled trucks. Max track width is 102” 13. All vehicles must have OEM working suspension front and rear. With a minimum of 1 inch compression travel. Bolt on traction bars are permitted. Air bag lines must be disconnected. Any truck with lift kit higher than 3 inches must have driveshaft loop and universal joints shields to cover the entire universal joint before competing in sled pulling event. Front suspension can not be block solid. Ex. (modified extended bump stops) Must have downward travel 9 14. Wheelbase and width of truck must be unaltered for the truck being used. 15. Truck and driveline being used (including front and rear axle, clutch, transmission, transfer case and drive shaft) must have been originally produced for diesel engine one ton or smaller pick-up truck. 16. Engine and radiator must be in original location as intended by manufacturer. 17. Frame, body, hood, bed and fenders must meet OEM specifications. Flat beds must be State Street Legal. Beds must have full floor. All window glass must be in place. Doors and windows must function up and down. No plexiglass windows. 18. All engine fans must be OEM shrouded. 19. A complete interior, including dashboard, door panels, headliner, etc., is mandatory. Two matching front seats are mandatory. Aftermarket seats are permitted; they must be fully upholstered. All factory controls (lights, signals, horn, windows, wipers, etc.) must be retained and be operative. Work Stock Diesel Trucks 1. Maximum vehicle weight: 8500 lbs. Weight is with driver 2. Hanging front weights are prohitibed. Added weights must be mounted and secured in bed of truck. No weights in the truck cab. Front mounted weights are not allowed, front bumpers must be O.E.M., lower brackets for snow plow frames are permitted, and no modifications that add weight are permitted (No hidden weights under the truck). 3. The body must be the OEM truck body. The body must retain full sheet metal. 4. The hood must be closed and securely latched while the vehicle is hooked to the sled. The complete OEM firewall and OEM floor pan is mandatory. 5. Four-wheel hydraulic functional brakes are mandatory. 6. The OEM chassis is mandatory. The engine must be in the OEM location for the body used. The vehicle must retain the full OEM chassis. Wheel tubs, back-half conversions, tube chassis, etc., are prohibited. 7. Radiators must be in the stock location and be of at least stock size. 8. An OEM transmission and transfer case are mandatory. They must have been an option on a one-ton or smaller pickup. 9. The OEM safety belt restraint system is mandatory and must be worn. 10. All vehicles must be equipped to direct exhaust upward. The exhaust must exit rearward of the driver’s compartment. Stacks exiting through the hood or fender well are prohibited. Two 3/8 inch diameter, minimum grade 5, bolts must be installed through the exhaust pipe in a cross pattern within one inch of each other as close to the turbo as is practical. 11. A 2.5lb ABC fire extinguisher is mandatory. 12. The fuel must be pump #1/#2 diesel only. Soy/Bio-diesel fuel is permitted. NITROUS OXIDE is prohibited along with other oxygen extenders as well as the use of PROPANE is also prohibited. All system components MUST be removed from the truck. 10 13. The use of multiple high-pressure common-rail fuel pumps is prohibited. Powerstroke engines with a single factory turbo may utilize a second HPOP. Pumps from different years in the same engine model may be interchanged. No ag govnors allowed. 14. The OEM fuel tank is mandatory and must be used. Racing fuel cells are prohibited and must be removed from the vehicle. 15. The hitch must be a receiver-style hitch; reinforcements are permitted. Reinforcements must not extend forward of the centerline of the rear axle or to the axle housing itself. Trick hitches are prohibited. The hooking point must be the rearmost point on the vehicle and must be rearward of the stock location of the tailgate. The hitch must be horizontal to the ground and stationary in all directions. Bumpers may be notched or removed. The hitch’s height from the ground may not exceed 26 inches. The hooking point must have a minimum 3.750-inch inside diameter opening for the sled hook. The hooking point will be measured to the center of the clevis loop. NO DRAWBARS ALLOWED. 16. Factory style or aftermarket air-air coolers are permitted. Water-to-air coolers are prohibited. Any means of cooling the air before the engine, except the air to air cooler is prohibited. No aftermarket heads/ OEM HEADS ONLY . No runner intakes allowed. 17. A complete interior, including dashboard, door panels, headliner, etc., is mandatory. Two matching front seats are mandatory. Aftermarket seats are permitted; they must be fully upholstered. All factory controls (lights, signals, horn, windows, wipers, etc.) must be retained and be operative. 18. Non-OEM rear-end housings are prohibited. It must have been an option on a one-ton or smaller pick up. 19. The vehicle must retain the full, original OEM steering gear. The vehicle must retain the original OEM power steering assistance, if it was so equipped. Additional stabilizers are permitted. Non-OEM power assist methods are prohibited. 20. Complete headlight and taillight assemblies (all) are mandatory and must be operative. Complete OEM windshield and windows are mandatory. Windows must be operative per factory specifications; that is, they must open and close via OEM electrical or mechanical means. 21. Suspension: Front: The upper mounting point for strut assemblies must be in the factory location. Adjustable caster/camber pillow ball mounts are permitted. The lower control arm may be strengthened provided factory-mounting points to chassis are maintained. The lower mounting point for the strut assembly may be modified for improved caster or camber. Strut tower braces, lower tie bars, sway bars, and limit straps are permitted. Traction bars and devices are permitted. Final decisions rest with the Technical Department. 22. Suspension, Rear: An OEM-style suspension is mandatory. Lowering or raising the vehicle height with suspension modifications is permitted. Traction bars and devices are permitted; they must be bolt-on only; welds are permitted for attachment to frame or axle housing. All OEM suspension mounting points must be retained and used. Sway bars, limit straps, and camber kits are permitted. The rear suspension can be blocked solid, compression stops must be adjustable. All rear suspensions must use at least one working shock absorber per wheel. Airbag spring assistance is permitted; airbag compressors must be disconnected. 23. Wheels and tires must have dot. approved number on sidewall. No cutting, grooving, shaping or sharpening of tire tread is permitted. No studded tires or chains allowed. On factory dual wheeled trucks only a 10 inch tire tread maximum width per tire and 35 inches tall. 35 x12.50 tires maximum on single wheel trucks. No dual wheels allowed on factory single wheeled trucks. 24. Non-OEM transfer cases are prohibited. The transfer case must have been an option on a one-ton or smaller pickup truck. 25. Non-OEM transmissions are prohibited. Aftermarket torque converters, valve bodies and internal components are permitted. Transmission brakes are prohibited. Any non-OEM floor-mounted automatic transmission shifter must be 11 equipped with a spring-loaded positive reverse lockout device to prevent the shifter from accidentally being put into reverse gear. A functional neutral safety switch is mandatory. All transmission lines must be metallic or high-pressuretype hose. All vehicles with engines running 4500 RPM or more and using an automatic transmission must be equipped with a transmission shield meeting SFI Spec 4.1 and must be labeled accordingly. A blanket-type shield is permitted; it must be appropriately labeled as meeting SFI Spec 4.1 and it must extend from the rear of the block to the front of tail housing with a minimum six inch overlap where it is fastened. All non-blanket type shields must incorporate two (or one, per manufacturer’s instructions) 3/4 inch by 1/8 inch straps that bolt to the shield on each side and pass under the transmission pan unless the transmission pan is labeled as meeting SFI Spec 4.1. All vehicles with engines running 4500 RPM or more and using an automatic transmission must be equipped with a flex plate meeting SFI Spec 29.1 and be covered by a flex plate shield meeting SFI Spec 30.1. 26. Non-OEM transmissions are prohibited. Aftermarket internal components are permitted. A clutch meeting minimum SFI Spec 1.1 or 1.2 is mandatory on all vehicles with engines running 4500 RPM or more. All manual transmissions must be clutch assisted. Sequential shifters are prohibited. All vehicles with engines running 4500 RPM or more and equipped with a manual transmission must have a flywheel shield labeled as meeting minimum SFI Spec 6.3 or greater. Applications for which an SFI Spec flywheel shield is not available may use a properly attached SFI 4.1 or 4.2 blanket that completely covers the bell housing; it must be attached to the block and extend rearward to the transmission with a minimum six inch overlap where it is fastened. 27. Must have rear drive loops/universal can ( at-least one center loop and a rear can covering the entire rear universal) 28. The turbocharger is limited to a stock-appearing, no s-300 /s-400 turbos allowed . Oem/factory make specific turbos only . Ex. (must have been available on a factory one ton or less truck) May use factory twins Ex. (6.4/6.7 powerstrokes) 29. Water injection is prohibited. All system components must be removed from the truck. 30. The vehicle must retain the original factory wheelbase and track width not to exceed 102 inches wide. 2.5 4X4 Diesel 31. Maximum vehicle weight: 8100 lbs. Weight is with driver 32. Ballast is permitted. Hanging front weights are ALLOWED. Ballast may be added in the bed of the truck. If used, ballast must be securely fastened to the bed. Final decisions rest with the Technical Department. 33. The body must be the OEM truck body. The body must retain full sheet metal. 34. The hood must be closed and securely latched while the vehicle is hooked to the sled. The complete OEM firewall and OEM floor pan is mandatory. 35. Four-wheel hydraulic functional brakes are mandatory. 36. The OEM chassis is mandatory. The engine must be in the OEM location for the body used. The vehicle must retain the full OEM chassis. Wheel tubs, back-half conversions, tube chassis, etc., are prohibited. 37. Radiators must be in the stock location and be of at least stock size. 38. An OEM transmission and transfer case are mandatory. They must have been an option on a one-ton or smaller pickup. 39. The OEM safety belt restraint system is mandatory and must be worn. 12 40. All vehicles must be equipped to direct exhaust upward. The exhaust must exit rearward of the driver’s compartment. Stacks exiting through the hood or fender well are prohibited. Two 3/8 inch diameter, minimum grade 5, bolts must be installed through the exhaust pipe in a cross pattern within one inch of each other as close to the turbo as is practical. 41. A 2.5lb ABC fire extinguisher is mandatory. 42. The fuel must be pump #1/#2 diesel only. Soy/Bio-diesel fuel is permitted. NITROUS OXIDE is prohibited along with other oxygen extenders as well as the use of PROPANE is also prohibited. All system components MUST be removed from the truck. 43. The use of multiple high-pressure common-rail fuel pumps is permitted. Powerstroke engines with a single factory turbo may utilize a second HPOP. Pumps from different years in the same engine model may be interchanged. No ag pumps/governors allowed. 44. The OEM fuel tank is mandatory and must be used. Racing fuel cells are prohibited and must be removed from the vehicle. 45. All engines turning 4500 RPM and higher must be equipped with a harmonic balancer or damper meeting SFI Spec 18.1. 46. The hitch must be a receiver-style hitch; reinforcements are permitted. Reinforcements must not extend forward of the centerline of the rear axle or to the axle housing itself. Trick hitches are prohibited. The hooking point must be the rearmost point on the vehicle and must be rearward of the stock location of the tailgate. The hitch must be horizontal to the ground and stationary in all directions. Bumpers may be notched or removed. The hitch’s height from the ground may not exceed 26 inches. The hooking point must have a minimum 3.750-inch inside diameter opening for the sled hook. The hooking point will be measured to the center of the clevis loop. NO DRAWBARS ALLOWED. 47. Factory style or aftermarket air-air coolers are permitted. Water-to-air coolers are prohibited. Any means of cooling the air before the engine, except the air to air cooler is prohibited. No aftermarket heads EX. (Wagler,Hamilton,Brodix) OEM HEADS ONLY . No runner intakes allowed. 48. A complete interior, including dashboard, door panels, headliner, etc., is mandatory. Two matching front seats are mandatory. Aftermarket seats are permitted; they must be fully upholstered. All factory controls (lights, signals, horn, windows, wipers, etc.) must be retained and be operative. 49. Non-OEM rear-end housings are prohibited. It must have been an option on a one-ton or smaller pick up. 50. Rear axle bolts must be covered by a cap or shield. 51. The vehicle must retain the full, original OEM steering gear. The vehicle must retain the original OEM power steering assistance, if it was so equipped. Additional stabilizers are permitted. Non-OEM power assist methods are prohibited. 52. Complete headlight and taillight assemblies (all) are mandatory and must be operative. Complete OEM windshield and windows are mandatory. Windows must be operative per factory specifications; that is, they must open and close via OEM electrical or mechanical means. 53. Suspension: Front: The upper mounting point for strut assemblies must be in the factory location. Adjustable caster/camber pillow ball mounts are permitted. The lower control arm may be strengthened provided factory-mounting points to chassis are maintained. The lower mounting point for the strut assembly may be modified for improved caster or camber. Strut tower braces, lower tie bars, sway bars, and limit straps are permitted. Traction bars and devices are permitted. Final decisions rest with the Technical Department. 54. Suspension, Rear: An OEM-style suspension is mandatory. Lowering or raising the vehicle height with suspension modifications is permitted. Traction bars and devices are permitted; they must be bolt-on only; welds are permitted for attachment to frame or axle housing. All OEM suspension mounting points must be retained and used. Sway bars, limit 13 straps, and camber kits are permitted. The rear suspension can be blocked solid, compression stops must be adjustable. All rear suspensions must use at least one working shock absorber per wheel. Airbag spring assistance is permitted; airbag compressors must be disconnected. 55. Wheels and tires must have dot. approved number on sidewall. No cutting, grooving, shaping or sharpening of tire tread is permitted. No studded tires or chains allowed. On factory dual wheeled trucks only a 10 inch tire tread maximum width per tire and 35 inches tall. 35 x12.50 tires maximum on single wheel trucks. No dual wheels allowed on factory single wheeled trucks. 56. Non-OEM transfer cases are prohibited. The transfer case must have been an option on a one-ton or smaller pickup truck. 57. Non-OEM transmissions are prohibited. Aftermarket torque converters, valve bodies and internal components are permitted. Transmission brakes are prohibited. Any non-OEM floor-mounted automatic transmission shifter must be equipped with a spring-loaded positive reverse lockout device to prevent the shifter from accidentally being put into reverse gear. A functional neutral safety switch is mandatory. All transmission lines must be metallic or high-pressuretype hose. All vehicles with engines running 4500 RPM or more and using an automatic transmission must be equipped with a transmission shield meeting SFI Spec 4.1 and must be labeled accordingly. A blanket-type shield is permitted; it must be appropriately labeled as meeting SFI Spec 4.1 and it must extend from the rear of the block to the front of tail housing with a minimum six inch overlap where it is fastened. All non-blanket type shields must incorporate two (or one, per manufacturer’s instructions) 3/4 inch by 1/8 inch straps that bolt to the shield on each side and pass under the transmission pan unless the transmission pan is labeled as meeting SFI Spec 4.1. All vehicles with engines running 4500 RPM or more and using an automatic transmission must be equipped with a flex plate meeting SFI Spec 29.1 and be covered by a flex plate shield meeting SFI Spec 30.1. 58. Non-OEM transmissions are prohibited. Aftermarket internal components are permitted. A clutch meeting minimum SFI Spec 1.1 or 1.2 is mandatory on all vehicles with engines running 4500 RPM or more. All manual transmissions must be clutch assisted. Sequential shifters are prohibited. All vehicles with engines running 4500 RPM or more and equipped with a manual transmission must have a flywheel shield labeled as meeting minimum SFI Spec 6.3 or greater. Applications for which an SFI Spec flywheel shield is not available may use a properly attached SFI 4.1 or 4.2 blanket that completely covers the bell housing; it must be attached to the block and extend rearward to the transmission with a minimum six inch overlap where it is fastened. 59. Must have rear drive loops/universal can ( at-least one center loop and a rear can covering the entire rear universal) 60. Bushing of any larger turbo size down to a 2.550 turbo is PROHIBITED. Inducer bore must be non-removable. Turbo compressor covers must be a true-bore inlet. Stepped covers are prohibited. Clipping of the compressor wheel is prohibited. The turbo wheel must measure no larger than 2.550'' in front of and behind the MWE. The turbo may utilize a stock map width enhancement (MWE) groove, but is to be no wider than .250” maximum. No MWE alterations will be allowed. All provisions allowing air to the wheel other than via the bore and the MWE groove are prohibited. Exhaust manifold/ Pedestal bolt pattern shall measure no larger than 3.500" x 2.750" (t-4 flange). Altering of the turbo housing to accommodate a smaller foot or base will not be permitted. 6.4 liter Powerstroke/ 6.7 liter scorpion engines may utilize the factory turbo configuration. The driver will be responsible for making the compressor wheel and bore accessible for Tech Officials to measure bore and inspect the compressor wheel. 61. Water injection is prohibited. All system components must be removed from the truck. 62. The vehicle must retain the original factory wheelbase and track width not to exceed 102 inches wide. 63. Truck must have a air kill or electric engine shut off 14 2.6 /3.0– 4x4 Mod-Diesel 1. Maximum weight of 8000lbs including driver, with a minimum weight of 7500lbs. 2. Ballast is permitted. Front hanging weights are allowed not to exceed 60 inches forward of the center of the front axle. This will be measured from center of front wheels to end of weight assembly. Ballast may be added in the bed of the truck. 3. The body must be the OEM truck body, including the full bed floor. The body must retain full sheet metal, aftermarket hoods are permitted. The hood must be closed and securely latched while the vehicle is hooked to the sled, No flatbeds permitted. 4. Front brakes only are required. 5. Vehicle must retain the oem chassis, no back have conversions, full tube chassis are prohibited 6. All drivers must have a valid state driver’s license and full fire suit. (see General Rules) which includes helmet. 7. Seatbelt/restraint system must be worn. 8. An OEM transmission and transfer case are mandatory. They must have been an option on a one-ton or smaller pickup. 9. All trucks must have at least six inch wide u-joint shields around the rear u-joint constructed of at least 1/4 inch steel or 3/8 inch aluminum that will safely contain the u-joint and the end of the rear shaft. All shields must be securely mounted to the vehicle. Any front shaft u-joint that is visible from the side of the truck must be shielded to contain the u-joint and the end of the shaft. 10. The engine is limited to a stock-appearing, Engine and transmissions can be interchanged between Dodge, Ford and GM as long as they came in a 1 ton truck or less from the factory. Complete engine must have stock appearance except where otherwise noted in these rules. Aftermarket intake manifolds are allowed, Front of engine block can be no farther forward than 17” of centerline of front axle. 11. All vehicles must be equipped to direct exhaust upward. Two 3/8 inch diameter bolts must be placed through the exhaust pipe in a cross pattern within one inch of each other, within 12” of the turbo. 12. A fire extinguisher system is permitted. It must be securely mounted. A complete OEM firewall is mandatory. 13. The complete OEM floor pan is mandatory. 14. Hand throttles permitted. The fuel must be pump #1/#2 diesel, Soy/Biodiesel fuel. No propane or NO2 permitted or any other oxygen enhancers. Racing fuel cells are permitted. 15. Maximum of one P7100 pump limited to one plunger per cylinder. The use of multiple high-pressure common-rail fuel pumps is legal. Powerstroke engines with a single factory turbo may utilize a second HPOP. 16. Hook point must be no closer than 44” of centerline of rear axle, hitch height maximum of 26”, with a Minimum of a 3.75” X 3.0” opening. Hitch point must be easily accessed. No “trick” type hitches permitted. Hitch must be stationary in all directions. Hitch must be frame mounted. Hitch must be mounted centerline of rear axle or behind. Hitch must not exceed a maximum of 25 degree angle from pivot point to hook point. ***No hitch support or adjusters, if fastened to rear axle housing shall be above the center line of the rear axle. Pivot pin of drawbar can be no forward than centerline of rear axle*** 17. Open rear axles are allowed must retain factory front axle 15 18. Must have air kill mounted in front of turbo or electronic kill if electronic controlled engine. Must have 2 inch steel ring at rear the truck for the sled to hook its cable to. 19. Hydraulic steering permitted. 20. Suspension, Front: The upper mounting point for strut assemblies must be in the factory location. Adjustable caster/camber pillow ball mounts are permitted. The lower control arm may be strengthened provided factory-mounting points to chassis are maintained. The lower mounting point for the strut assembly may be modified for improved caster or camber. Strut tower braces, lower tie bars, sway bars, and limit straps are permitted. Traction bars and devices are permitted. 21. Lowering or raising the vehicle height with suspension modifications is permitted; must be bolt on only; welds permitted for attachment to frame or axle housing. Sway bars, limit straps, and camber kits permitted. Traction bars and devices are permitted, Blocked suspension is permitted. No air bags. 22. Tires must be DOT approved street tires. Cut tires are prohibited. Maximum tire height 35 inches, 102” Max outside tire to outside tire, No Studded tires or chains, No alteration to tires allowed, No bar or terra tires, Dual rear tires only permitted. 23. Non-OEM transfer cases are prohibited. The transfer case must have been an option on a one-ton or smaller pick-up truck. 24. Non-OEM transmissions are prohibited. Aftermarket torque converters, valve bodies and internal components are permitted. 25. Transmission brakes are prohibited. Any non-OEM floor-mounted automatic transmission shifter must be equipped with a spring-loaded positive reverse lockout device to prevent the shifter from accidentally being put into reverse gear. A functional neutral safety switch is mandatory. All transmission lines must be metallic or high-pressure-type hose. All vehicles using an automatic transmission must be equipped with a transmission shield meeting SFI Spec 4.1 and must be labeled accordingly. A blanket-type shield is permitted; it must be appropriately labeled as meeting SFI Spec 4.1 and it must extend from the rear of the block to the front of transmission main body the bell housing area is to be completely covered six inch overlap where it is fastened. All non-blanket-type shields must incorporate two (or one, per manufacturer’s instructions) 3/4 inch by 1/8 inch straps that bolt to the shield on each side and pass under the transmission pan unless the transmission pan is labeled as meeting SFI Spec 4.1. All vehicles using an automatic transmission must be equipped with a flex plate meeting SFI Spec 29.1 and be covered by a flex plate shield meeting SFI Spec 30.1. 26. Non-OEM transmissions are prohibited. Aftermarket internal components are permitted. A clutch Meeting minimum SFI Spec 1.1 or 1.2 is mandatory on all vehicles. All manual transmissions must be clutch assisted. Sequential shifters are prohibited. All vehicles equipped with a manual transmission must Have a flywheel shield labeled as meeting minimum SFI Spec 6.3 or greater. Applications for which an SFI Spec flywheel shield is not available may use a properly attached SFI 4.1 or 4.2 blanket that completely covers the bell housing; it must be attached to the block and extend rearward to the Transmissions with a minimum six inch overlap where it is fastened. 27. The vehicle is limited to a 2.6 inducer bore single turbocharger. The compressor wheel must protrude into a 2.6” bore for 1/8”. The inlet will be measured using a 2.605 inch plug the plug must not be able to enter the inducer bore. A stock map width enhancement (MWE) groove must be inside neck area where intake cover is measured. No MWE groove will be allowed that has a width greater than .200”. All provisions allowing air into the wheel other than via the bore and the MWE groove are prohibited. The vehicle driver will be responsible for making compressor wheel accessible for tech personal to measure bore and be able to inspect compressor wheel. All primary blades must protrude into the bore. ********************************************************************************************** 2016 3.0 Smooth bore PPL legal turbos will also be allowed in the class (The turbo is the smooth faced intake housing limted to a 3.0 inch inlet with no map groove ring, with all air entering the 3.0 inch intake wheel opening. Wheel must protrude 1/8th inch inside of the opening) 16 29.Water injection is prohibited. All system components must be removed from the truck. 28. Air to Water Intercoolers are allowed. Dumping/draining of intercooler within 100 feet of track is prohibited. 29. The vehicle must retain the original factory wheelbase and not to exceed 102” wide. Maximum of 1 ton truck chassis only allowed. Dual front wheels are prohibited. 466 Hot Farm Tractor Rules Weight -10,500 LBS. 1. Tractors must be agricultural tractors having chassis, engine, clutch, transmission, differential housing, hood and grill of the manufacturer. OEM Cylinder Head. NO Recast, No Aluminum, No Overhead Cams Allowed. Engine, clutch, transmission and differential housings must be bolted together as one unit in stock location – OEM Length & Location from rear end housing to front of the engine. No Component. Injection Pump no larger than an A-Pump, one plunger per cylinder. Tractors must have wide front axle and must track within rear wheels. Tractors must have steel flywheel and clutch components. NO CAST. All Clutch housing must have SFI Blanket or steel around flywheel. (2015 All Tractors MUST HAVE SFI Blanket). Manifolds – OEM Intake and Exhaust. 2. Cubic inch limit is 466. 3. Water Injection Is Allowed 4. Intercoolers Are Allowed 5. Maximum Turbo Size 2.8 Compressor Wheel by 3.5 Exhaust T-4 Foot. No Billet Intake Wheels. No Modifications to the Compressor Wheel Or Housing - Only To Plumb Air Intake Pipe. 6. Must have side shields (Aluminum .125 or steel .90). Must have quick release fastener to remove shields. 7. Exhaust must discharge vertically upward. Must be at least 18 inches above hood. No curved pipes or rain caps allowed. Pipe must be cross bolted with two 3/8” Grade Five bolts within 1 inch of each other in vertical pipe and two 5/16” Grade Five bolts within 1 inch of exhaust housing. 8. Vehicle with a plastic or fiberglass hood must be shielded in the turbo area with a minimum of aluminum .125 or of steel .60 9. Minimum drawbar length of 18 inches from center of rear axle to point of hook. Drawbar must be rigid in all directions with maximum of 20 inches from top of hitch to the ground. 10. All tractors must have air shut off at rear of tractor and must also be able to be operated manually by the operator from the seat. 11. Rear wheelie bars – Pads on bottom of bars a minimum of 5 inch square or 4x6 pads. Pads to be a minimum of 32 inches rearward from the center of the rear housing. Pads maximum of 10 inches off ground. Width of pads to be a minimum of 20 inches outside to outside. Minimum 12 inch high bumper bars – top to be fastened to wheelie bar frame. Wheelie bars must support weight of the tractor for weight class being pulled. 12. Tires – Maximum 24.5 x 32 not over 38 inch. Top cut only. Ag Tires Only. 13. Mandatory Cage or Roll Bar (2015 Season ALL tractors MUST HAVE SFI Roll Cage) 14. Diesel Fuel only. No Hot Fuel. Only additive allowed – will be approved lubricants. 17 15. Driver MUST wear SFI Approved Firesuit, Helmet, Gloves, Shoes, Head/Helmet Sock. Seat belt must be worn when pulling. 16. All tractors must have neutral safety start switch that will allow starter engagement only in neutral or park. All tractors must have a neutral safety light. A white light minimum of 2 inches in diameter must be mounted within 30 inches of hooking point and within 6 inches of center line. 17. Deadmans throttle must have at least 2 springs 18. Removal of PTO and Hydraulics allowed 19. Tractors must have working brakes. 20. Tractors must have fenders that consist of a solid barrier between the driver and any part of the rear tires. The barrier must be able to sufficiently support the weight of the driver and must extend a minimum of 6 inches horizontally at the top and a minimum of 36 inches wide at the top. 21. Fire extinguisher must be mounted within reach of the driver. 22. Fuel dump valve is required. 23. No accelerants, propane or alcohol mixtures allowed 24. All tractors must have front ski. Maximum 4 inches off ground. 25. All tractors must have stock wheel base and frame length. Extended weight frames will be allowed. Total length of weight frame no more than 13’ from the center rear axle. 10,000 540-Pro Farm Tractors must be agricultural tractors having chassis, engine, clutch, transmission housing, differential housing, transmission, hood and grill of one manufacturer. OEM cylinder head must be for series engine used-no recast, No aluminum, No overhead cams allowed. Engine, clutch, transmission, and differential housings, must be bolted together as one unit. All bolts connecting all housings must be in their stock location-OEM length & location from rear end housing to front of engine. No component powertrains. Repower engines must use original equipment size and type injection pump for the tractor being entered, or injection pump must be maximum of one (A) line pump (German Bosch, one plunger per cylinder). No P-pumps. No Billet A pumps. Tractors must have wide front axles. Tube chassis allowed. Front wheels must track within rear wheels. Tractor must have steel flywheel and clutch components. No cast parts allowed in clutch system. 1. Engine cubic inch limit of 540 ci. 2. Vehicles must have OEM cylinder head and must be for series engine used - No recast; No aluminum; No overhead cams allowed. 3. Diesel tractors only. Diesel Fuel only. No accelerants. 4. Intercoolers and water injection allowed. No alcohol allowed. 5. Turbocharger must be under hood. - Turbocharger must have a restrictor plate 1/4 inch thick with a hole no larger than 2.8" in diameter to be measured 2" from the compressor wheel blade. All air must go through the 2.8 turbo inlet restrictor plate. There must be only one turbo going through one pressure stage. No welding to the turbine housing will be allowed. No welding to the compressor housing in order to make it fit into the 7.75 dimensions will be allowed. 6. Exhaust must discharge vertically upward above highest point of tractor, exception of roll bars, and be securely attached. Exhaust must be at least 18: above the hood an no curved pipes or rain caps allowed. Exhaust pipe must be cross-bolted with two 3/8: grade five bolts with 1: of each other in vertical pipe and two 5/16: bolts within one inch of exhaust housing. 18 7. Vehicle with a plastic or fiberglass hood must be shrouded in the turbo area with a minimum metal thickness of .060" or 1/16. 8. All engine fans must be shrouded with steel 1/16" or thicker 360 degrees or factory. 9. Minimum drawbar length 18: from center of rear wheels to point of hook. Draw-bar must be rigid in all directions. Maximum 20" from top of hitch to the ground. Drawbar must be parallel to the ground. Hitch must be horizontal - Not vertical. No cast iron drawbar components. Draw bar must be horizontally pined. 10. All tractors will require: a. Air shut off - must also be able to be operated manually (by the operator from the seat of the tractor). b. Flywheel protection in the form of either: i. A scatter blanket with six straps ii. 6" x 3/8" steel around the flywheel area. c. Rear wheelie bars installed in accordance with the following specifications: i. Pads on bottom of bars to be a minimum of 5 in. sq. pads. ii. Pads to be a minimum of 32" rearward from the center of the rearend housing. iii. Pads maximum of 10" off the ground. iv. Outside to outside width of pads to be a minimum of 20". v. Minimum 12" high bumper bars - top to be fastened to stabilizer bar framing. vi. Bars must support weight of tractor for weight class being pulled. d. Deadmans throttle. Throttle must have at least 2 springs. e. Neutral light - Light must come on in neutral & start in neutral, with light on. f. Side shields are allowed and must be made out of .060" or 1/16" metal. Harmonic balancer to be shielded to be contained within vehicle. g. Harmonic balancer to be shielded to be contained within vehicle. h. Front skid bars mandatory. i. Tie bars required from front of clutch housing to rear axle housing. j. Tractors must have engine side shields, side shield material to be minimum .060 inch thickness. Plastic or fiberglass hoods must be shielded in the turbo area. 11. Maximum tire width is to be 24.5" US or 650 metric, maximum rim diameter of 38" No cut tires or puller 2000 H.P. No alterations to front edge of bar, tread, or cleat of tires. No puller tires of any kind. 12. Removal of PTO and hydraulics (rockshafts) allowed - if not removed, PTO shafts must be covered with a safety shield. 13. The frame and wiights must not extend any further than 12" from center of the rear axle to further most point excluding tow hook. The wheelbase must not exceed 114" 14. Competing vehicles must have working rear wheel brakes. 15. Competing vehicles must have fenders that consist of a solid barrier between the driver and any part of the rear tires. The barrier must be able to sufficiently support the weight of the driver and must extend a minimum of 6: horizontally at the top and be a minimum of 36" wide at the top. 16. Vehicle must have a rollover protection bar or cage that is at least as high as the top of the drivers head/helmet. Rollover protection must be fastened at least two points to the rear axle housing. Factory style flip down tops allowed. Rollover protection must be able to lift one rear wheel when pulled horizontally from the top of the bar/cage without damage to the rollbar/cage. 17. Top 3 finishing tractors are subject to inspection. 18. Driver must wear fire suit and helmet. 19. Fire extinguisher is required. STREET LEGAL SEMI-TRUCKS This class is for street legal, licensed semi-trucks. This is truly an OPEN class for all semi-trucks, but it is definitely NOT a PURE STOCK class. Weight of Truck: 22,000 lb. Maximum 19 1. All entries must be a Street Licensed Semi Truck. The owner must furnish a current registration card for the vehicle at the time of registration and the driver must have a valid CDL license. Truck must be capable of pulling a trailer on the highway. All trucks must be driven to pulls. 2. Ballast is not permitted at any point on the chassis. Special trucks, such as oil field trucks that carry additional weight not normally found on a “road ready” truck are not permitted in this class. 3. Batteries must be securely mounted. They may not be mounted in the driver compartment, or forward of the radiator support. 4. Trucks must have a minimum of 66” from the center of the tandems to the first structural obstruction such as the bunk, toolbox, cab, etc. This is the minimum swing clearance needed to pull a trailer. 5. The driver is the only person allowed to ride in the cab while vehicle is on pulling track. The driver may not leave the seat while vehicle is on the pulling track. All direction will be taken from the flagman on the track. 6. Driver must use seatbelt and shoulder harness if the vehicle is so equipped, when hooked to the sled. 7. Engine must be stock appearing. Engines in the truck must have been available in a class 8 series truck. 8. Exhaust must be directed away from the fuel tank and driver and exit upward. Two 3/8 inch diameter bolts must be installed through the exhaust pipe in a cross pattern within one inch of each other as close to the final turbo as is practical. 9. A fire extinguisher is mandatory. A fire extinguisher system is permitted. 10. Normal pump diesel is the only fuel permitted in the class. 11. Alteration/modification/replacement of the (OEM) original factory fuel pump is not permitted. No fuel pump may be modified with Sigma parts. A Cummins engine must have a Cummins fuel pump- A Detroit must have a Detroit Fuel pump- A Cat must have a Cat fuel pump. Electronic engines must remain electric. No mechanical fuel pumps permitted on electronic engines. 12. All engines turning 4500 RPM and higher must be equipped with a harmonic balancer or damper meeting SFI Spec 18.1. 13. Hitch height is to be determined by promoter. Hitch must work from the fifth wheel with the fifth wheel centered between centerline of the front axle to the center of the two axles. 14. No further forward then the center of the front axle and no further back then center between the two axles. 15. A complete interior, including dashboard, door panels, headliner, etc., is mandatory. Two matching front seats are mandatory. Aftermarket seats are permitted; they must be fully upholstered. All factory controls (lights, signals, horn, windows, wipers, etc.) must be retained and be operative. The use of hand-throttle controls is prohibited. 16. The vehicle must retain the full, original OEM steering gear. The vehicle must retain the original OEM power steering assistance, if it was so equipped. Additional stabilizers are permitted. Non-OEM power assist methods are prohibited. 17. Street Equipment: Complete headlight and taillight assemblies (all) are mandatory and must be operative. Complete OEM windshield and windows are mandatory. Windows must be operative per factory specifications; that is, they must open and close via OEM electrical or mechanical means. 18. The use of air bags is permitted. However no air may be added to or removed from the air bags while the truck is hooked to the weight transfer machine. The height of the hitch must remain the same from start to finish. Any change in the hitch height will be cause for disqualification. Chaining or blocking of drive axles is not permitted. 20 19. The tires must be DOT street tires. Cut tires are prohibited. 20. Transmission must have been available in a class 8 truck from factory 21. A single turbocharger is the maximum permitted. *EXCEPTION- A factory 2006, 2007, 2008 Cat twin turbo is permitted with the factory-installed twin turbo set-up and absolutely no modifications. Also NTC 475 Cummins factory twin turbo set-ups are allowed. 22. Water injection in any form is not permitted. No ether, alcohol, nitrous or other combustible (propellant) liquid or combustible material may be injected into the turbocharger or any part of the air intake system. 12,000 & 15,000 Out of the Field Farm Stock 1. Open to any year Tractor 2. Tractor cannot weigh more than 12,000 & 15,000 for the class it’s competing. 3. Tractor must be all O.E.M, Including factory Hitch & Exhaust 4. 2 wheel drive tractors only, (NO 4 WHEEL OR DUEL TIRE TRACTORS PERMITTED) 5. No Riders 6. All “General Rules Apply” PULLING PROCEDURES: COMPETITION NUMBERS: All vehicles are required to display their assigned competition/exhibition numbers (in the upper left / right hand corner of the windshield, depending on direction of the pull) at all pulling events. Competition numbers are issued to ALL pullers only and are assigned to one truck only. Registration for all classes ends 30 minutes before the scheduled start of pulling. Unless other arrangements have been made with the Pull Director / Promoter on day of event. DRIVERS MEETING: All drivers must attend the drivers’ meeting. The meeting is typically scheduled 15 minutes before the pull starts. Failure to attend the drivers’ meeting may result in disqualification and loss of entry fees for that event. It is the driver’s responsibility to find out when and where the meeting is to be held. STAGING: Once a vehicle reaches the front of the staging area for a run, it must be prepared to fire and pull. To be a legitimate pull winner, a contestant’s vehicle must self-start. Push starting or push-staging any vehicle is prohibited. Staging must be done under the vehicles own engine power. Hoods must be closed and securely latched prior to hooking to the sled. PULLS: All events with pulls scheduled over two days will consist of two separate pulls. The order for the each pull will be determined by drawing random numbers. To constitute an official pull, a truck must self-start, self-stage, hook and attempt to pull. For all classes of competition, an individual truck cannot be used for multiple entries. Vehicles must remain in one class with one registered driver for the duration of the event. All pullers will have two chances to move the sled if they let off the throttle before the 100 foot marker. The truck and sled may coast past the marker. In the event of a legitimate mechanical breakdown, the puller will be allowed to unhook from the sled, pull off to the side and fix the malfunction, upon approval by the starting / flagger or Competition Director/Promoter. The truck may not return to the pits. The pull will continue during the repair. If it is the last truck in the class, the puller will have five minutes to hook from the time the sled is ready. If a truck has a legitimate mechanical failure in the staging line, the puller may drop back in the order until it is repaired. The truck may not return to the pits. If it is, or becomes, the last truck in the class, the puller will have five minutes to pull from the time the sled is ready. Faking a 21 mechanical failure in order to obtain a better position in line will result in disqualification. The Competition Director/Promoter decision is final. The track will be re-dressed after every truck pulls, or as the weather dictates. DISQUALIFICATIONS: Any portion of any wheel crossing or touching the boundary lines while pulling will result in disqualification. Disregard for any flagman or official is grounds for disqualification. Any driver and/or pit-crew member found to be under the influence of alcoholic beverages or drugs, regardless of amount, will be ejected from the event. Such a condition is cause for suspension, fine, and/or revocation of competition privileges. Any loss of ballast while under the green flag will result in disqualification. Extending any portion of the driver’s body outside the driver compartment while the vehicle is hooked to the sled is grounds for disqualification. REQUIRED CREDENTIALS: All pullers must have a valid state driver’s license endorsement. PROTESTS: Any protests must be made before the class/division is done pulling and the person protesting must be pulling in the same division & weight class. PROTEST MUST BE SUBMITTED IN WRITING. And Within 30 minutes of last vehicle pulling in that class, Only one item per protest and a FEE of $300.00 will be required. Protestor’s TRUCK will be checked first and fee will be returned to protestor if protested truck fails inspection. If protested truck passes inspection, $200.00 will go to owner and $100.00 to Promoter/Tech official. Promoter / Tech Official will have the final say of any disputes or placing’s. THIS GOES FOR ALL TRUCK/TRACTOR CLASSES • Any person who blocks the track with a truck or other means for the purpose to delay or interfere with the event (other than the promoter or track official) will be BARRED FROM PULLING for 1YR AND 10 DAYS. No one other than event promoter, track officials and track crew, and operators in their truck are permitted on the track while event is in progress • No out of state checks unless approved by Promoter • First puller in each weight class will be test puller and will be permitted to immediately pull again or drop to 6th position for his/her second attempt, no more dropping to last position. The distance from second attempt will be the distance recorded in that weight class • DUE TO INSURANCE: ALL OPERATORS MUST WEAR SHOES, SHIRTS, & PANTS. NO SHORTS OR OPEN TOE SHOES PERMITTED WHILE PULLING. ALSO ANY PULLER OR SPECTATOR THAT BRINGS A GOLF CART, GATOR, ETC., MUST BE OF LEGAL DRIVING AGE OF 16YRS OR OLDER TO OPERATE ON THE PULLING GROUNDS (SPECTATOR SIDE, PIT, OR TRACK AREA) • The track officials’ / promoter’s decision is final : The flagman has control of the pull at all times. • Announcements made on the day of event to take precedence over any mailed/ advertised information Sudlersville Fire Company Truck & Tractor Pull Contact Scott Kinnamon Cell# 410-490-9064 Scott_kinnamon@yahoo.com Cecilton Fire Company Truck & Tractor Pull Contact John Dixon Cell# (443)-350-6645 22