PowerPoint Presentation - Nozzle Ring Dec 4, 1998

advertisement

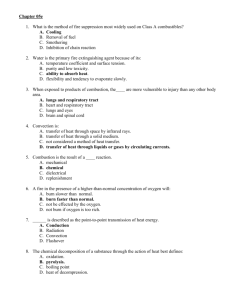

Combustion Catalyst Manufactured by: Renergi The MERGI effect Combustion Catalyst MERGI The MERGI effect Fuel Additive Ignition Catalyst Disperse Reduces Ignition Delay Stabilize Gradually Burning Pre Injection Pre Combustion Fuel Fuel High demand for “light” fuels: gas, petrol.. Availability of HFO Straight Distillate – HFO Blends + Deterioration of Marine Fuel Reduction of the willingness to ignite Combustion Air Fuel Smallest Particles Largest Surface of Droplets Mechanical Solutions: Turbo Blower Increase Injection Pressure 400-2000 bar Fuel Problems = Asphaltenes Polar Vanadium empowers the polarity Building of agglomerates of asphaltenes Agglomerates are hard to reverse Let's look at some models and lab tests Single asphaltene Four asphaltenes building up to an agglomerate Disperse Asphaltenes Reduce Polarity Avoid Asphaltenes building up to an agglomerate Excellent dispersing aromatics are Toluene Benzene Let's see the results in a Lab-Test Lab test dispersing Asphaltenes Before After MERGI’S FUNCTION As an additive Dispersing Asphaltenes Keeping them separated As a catalyst Reduction of ignition delay Catalysts: Metal versus Organic Reduction Ignition of Ignition Delay Delay Injection Time Ignition Catalysts - different types Metal Catalysts Iron, Fe. Zinc, Zn. Copper, Cu. Aluminum, AL. Magnesium, Mg. Carcinogenic Galvanizing Electrolytic Spoils Pumps Effects ? Disadvantages of metal catalysts Reversing Environment Catalysts - different types Free Radicals Organic Catalyst [-O-H] & [-O-N] Nitrates [-O-N] Chemical Soot Blowing Producing NOx [-O-H] Structures Xylitol: HO-CH-(CH-OH)3-CH2-OH MERGI uses………………………… Secret Reducing Ignition Delay Scientific Data (Constant Volume Bomb) Diesel Oil 10 % Ignition Delay Reduction HFO 8.8 % Ignition Delay Reduction Reduction of Ignition Ignition Delay Delay MERGI Gas Oil 10% HFO 8.8% Injection Time Ignition Reduction Ignition Delay f(P,T) = Ignition, Combustion Slow Steaming: dP/dt and dT/dt low 80% Load: dP/dt and dT/dt optimum Reduction of ignition delay strong effect on Combustion Specific fuel consumption Test on M/V Esso Slagen Reduction SFC & Soot Test on MTTest Esso onSlagen MT Esso Slagen Specific Fuel Consumption Marintek “A reduction of the ignition delay will generally be beneficial and should result in a more efficient and complete combustion.” Effect on Fuel Consumption Fuel Consumption Reduction DNV Rapport No 85-6115 Fuel Oil Consumption Tests - M/T “VINGA” “The specific fuel consumption of the engines was reduced with 4% when the combustion catalyst MERGI was applied” Fuel Consumption Reduction Aboitiz Jebsen, Fuel Management Dep. MV “MILLENIUM DRAGON”, MV “MILLENIUM EAGLE” MV “MILLENIUM TIGER” 6.2% -8.0% reduction in the specific fuel oil consumption Aboitiz Jebsen The Millennium vessels – 3 sister vessels TAXI Amsterdam Blind test Taxi Amstelland B.V. 2 Juni 1995 18 14.0% Km/L Km/L (Car-MERGI) 16 14 13.2 12.8 12.8 12.2 15.5 11.8% 12.7 12.1 9.1 11.3 7.6 8 10.0% 8.0% 8.5 8.5 12.0% 12.7 11.8 12.2 10.7% 12 10 15.2 14.5 14.6 8.3 8.0% 7.5 7.6% 6.0% 7.1% 6.2% 6 4.9% 5.0% 4.8% 4.0% 4 3.1% 2.0% 2 0 0.0% Autocar Models Norwegian Army Vestre Oslofjord Forsvarsdistrikt Fuel Consumption with and without Car-Mergi (Test 14 months) 18 16,0% 16,94 16 15,38 14,3% Verbruik 1:X 14,0% Verbruik + MERGI 1:X Besparing 14 10,1% 12 10,0% 10 10 9,34 7,8% 8,0% 7,1% 8 6,9% 6,0% 5,52 6 4,52 4,83 4,83 4,0% 4 3,19 3,44 2,0% 2 0 0,0% VW Vento 1992 Ford Busje 1992 MB Autobus 1991 Ford Cargo 1984 Ford Cargo 1988 Reduction FuelConsumption Kilometers per liter Fuel 12,0% Maintenance Reduction P&O Nedlloyd MV Oriental Bay IHI Sulzer 9RTA84 C 40,000 BHP @ 89 RPM Fuel 380 cSt Fuel consumption 120 Tons/Day Clogging up of Nozzle rings with carbon residue, 1.5-3 mm Maintenance interval turbines ≤ 4000 hours Nozzle Ring - M/V Oriental Bay Dec 4, 1998 Nozzle Ring - M/V Oriental Bay March 22, 1999 December, 1999 Nozzle Ring - M/V Oriental Bay December, 1999 P&O Nedlloyd Results Maintenance intervals < 4000 hours Maintenance intervals = 15000 hours. Results during operation P&O Nedlloyd M/V Bremer Reeder Info M/V Stolt Sunrise Info J.P. Pedersen & Son Emission reduction Soot CO HC NOx Wroclaw University of Technology Soot reduction Wroclaw University of Technology CO reduction Wroclaw University of Technology NOx reduction NOx Normal Combustion Temp 1500 °C NOx when Temp > 2000 °C Hot Spots NOx Reduction - Gas Treatment Exhaust Gas Catalysator Reduction - Engine Twin Injection Injection with water Common Rail Fuel Injection Reduction - Fuel Reducing the ignition delay Combustion Catalyst MERGI Combustion Catalyst MERGI Maintenance Saving Fuel Saving Emission Reduction Installation of MERGI Dosage Unit Serv. Tank Engine Sep. Sett. Tank Trans Pump MERGI Dos. Unit Suct. Filter Storage Tank MERGI Combustion Catalyst More questions? Decide Which vessels / engines do you have in mind? Combustion Catalyst MERGI The fuel saving alone more than pays for the cost of using MERGI Complete Combustion gives: Less maintenance Fuel saving Reduction of CO, NOx,and HC Emissions Combustion Catalyst MERGI Decide Which vessels / engines Start today We like to service you in reducing operational costs Renergi M/V Bremer Reeder Type of fuel : Diesel Oil. Immediately: clean exhaust and slow steaming was now possible. Changes during 7 weeks : cleaner boiler, rpm raised from 850 to 860. Cylinder temperature: decrease 10 dg. Changes next 6 weeks : cleaner filters, turbo pressure raised 1,75 - 2,0 bar. Max cylinder temp difference : now 15 dg, before 60 dg. Time between cleaning lube oil purifier slowly increased 100% Inspection of injectors : before 2000 h. After 6000 h. Lower fuel consumption. This mainly because it was now possible to run the engine at any load without having soot problems. Back Test on MT Esso Slagen Back Wroclaw - investigation Exhaust Gas Temperature Reduction Temperature Exhaust Gases (°C), standard fuel and fuel+MERGI, in relation to Engine Loading 700 50 655 661 40 600 500 Temperature in Celsius 514 T (With MERGI) T Difference 30 474 23 400 20 20 368 300 345 244 234 10 234 200 224 80%Load 0 0 100 -6 Back 0 -10 9 100 200 Engine Loading (N=1600 1/min) (Pmax= 377) 300 377 Temperature Difference in Celsius 40 T (No MERGI)