Pulleys Wheels and Axles

advertisement

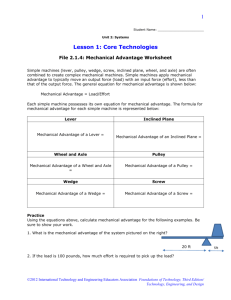

Simple Machines WHEEL AND AXLE PULLEYS The Wheel and Axle The wheel and axle is another type of simple machine that moves objects across distances. Wheels help move objects along the ground by decreasing the amount of friction between what is being moved and the surface. The work of this simple machine can result from the larger wheel being utilized to turn a smaller axle wheel. The bigger the wheel, the greater the twisting force (torque) that can be applied to the axle. The Wheel and Axle Work can also result when an axle is used to rotate wheels, such as the example of a rear axle and wheels of a truck. The effort (force) is applied to the axle at a point close to where the axle turns. This can be equated as the effort (force) distance. When effort (force) is applied to the axle, the mechanical advantage will be less than one but the speed is enhanced. The distance between the point where the wheel touches the ground and the point where the wheel turns can be called the resistance force (load) distance. These two distances are equal to the radius of the axle and the radius of the wheel, respectively. The Wheel and Axle To calculate the mechanical advantage of a wheel and axle assembly divide the radius of the wheel by the radius of the axle. Example: What is the mechanical advantage provided by a car's steering wheel assembly when the radius of the steering wheel is 6 inches and the radius of the axle is 1 inch? The Wheel and Axle Effort (force) is being applied to the steering wheel and therefore multiplied, providing torque on the axle six times greater than the effort (force) applied to the wheel. The trade-off, however, is that the steering wheel travels six times farther than the axle does during one full rotation. Use the formula below to calculate the amount of effort (force) required when using this simple machine. Effort × Circumference = Resistance Force × Circumference (Force) × (Wheel) = (Load) × (Axle) In the drawing below of a well crank (windlass), the handle is attached to a 2-inch radius axle. The turning circumference of the crank is 16 inches. How much effort (force) is required to lift a bucket of water weighing 40 pounds? The Pulley A pulley can be considered as a circular lever. ◦ It is a wheel with a grooved rim and axle with a rope, belt, or chain attached to it in order to change the direction of the pull and lift a load. Mechanical advantage for pulley systems can be found using the following formulas: The effort (force) distance is the radius of the pulley (length from the axle to the side of the rope being pulled). The resistance force (load) distance is the radius of the pulley from the axle to the load-carrying side of the rope. Pulleys are used to lift heavy loads and can be found in block and tackles, cranes, hydraulic systems, and chain hoists. They change the direction of effort (force) making it easier to lift the object or they enhance the effort (force). Or Types of Pulleys There are three types of pulleys: fixed moveable compound The mechanical advantage of pulley systems depends on the number of ropes, chains, etc. supporting the load. For example, using two supporting ropes to lift a resistance force (load) of 40 pounds would give you a mechanical advantage of 2. Fixed (Single)Pulley A fixed (single) pulley is attached to a stationary object like a wall or ceiling. It acts as a first-class lever having the fulcrum at the axis and the rope acting as the bar. Fixed (single) pulleys only change effort (force) direction (you can pull down on the rope to lift the load instead of pushing up on it). They do not enhance the effort (force). ◦ Effort (force) distance equals resistance force (load) distance and, therefore, each foot of pull on the rope will lift the load one foot. It provides no mechanical advantage (MA = 1). ◦ Example: The fixed (single) pulley has a resistance force (load) at one end of the rope. The other end must have effort (force) applied downward to raise the load. The effort (force) is equal to the load in this pulley system and there is no mechanical advantage, with the MA equal to 1. Movable Pulley A movable pulley moves up and down with the effort (force). It acts as a second-class lever having the resistance force (load) between the fulcrum and the effort (force). Unlike the fixed (single) pulley, it cannot change the direction of the effort (force). Moveable pulleys, however, enhance effort (force). Their mechanical advantage is greater than 1. The trade-off is that the effort (force) distance is greater than the resistance force (load) distance. The moveable pulley has the resistance force (load) supported by both the rope ends (the rope end attached to the upper bar and the rope end to be pulled effort [force] in the upward direction). The two upward tensions are equal and opposite in direction to the load. The mechanical advantage is 2. Compound Pulley A compound pulley utilizes both a fixed (single) pulley and a movable pulley. Compound pulleys provide both a change in the direction of the effort (force) as well as dramatically decreasing the effort (force) required to lift the resistance force (load). The mechanical advantage of this type of pulley is 2. The effort (force) distance, however, like with the moveable pulley, will be greater than the resistance force (load) distance. Note: The mechanical advantage of pulley systems can also be calculated visually by counting the number of ropes, chains, etc. supporting the load. For example, in the illustration of the compound pulley, there are two supporting ropes to lift the resistance force (load), giving the pulley system a mechanical advantage of 2. Compound Pulley Block and Tackle A T of several fixed and moveable pulleys is known as a block and tackle. Archimedes showed that by using multiple pulleys, a large ship fully loaded with men could be pulled by a single man's effort. Efficiency of a Pulley System 1. To calculate the efficiency of a pulley system, first determine the mechanical advantage. 2. Next, determine the velocity ratio by dividing the distance moved by effort (force) by the distance moved by the resistance force (load). 3. Finally, divide the mechanical advantage by the velocity ratio and multiply this number by 100 percent. Example: A pulley system can lift an object weighing 50 N with an effort (force) of 10 N. The input distance is 5 m and the output distance is 0.5 m. What is the efficiency of the pulley system?