Experience machining precision accelerator components

advertisement

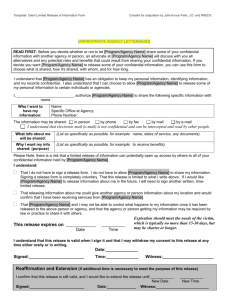

Experience in machining precision accelerator components Looking back and ahead VDL Enabling Technologies Group Company Confidential Company Confidential Contents Company introduction Looking back and ahead Cost study Ambitions for CLIC Summary 2 Company Confidential VDL Groep Sub contracting mechatronic systems module assembly part and sheet metal Surface treatments plastic processing other specialties Bus group Finished products touring cars public transport bus mini and midi busses Chassis modules second hand trade Established in 19 countries 85 operating companies > 10,000 employees, privately owned Turnover 1.8 billion (2013) medical equipment process installations consumer products production automation various products packaging equipment Car assembly Company Confidential NedCar VDL ETG: our company DNA COMPETENCES Vacuum Handling Positioning R&D support Prototyping Complex mechanical parts Modules Volume production Supply Chain Management support Fully integrated systems Value Engineering PRODUCTS Sustaining & After sales support QLTC Management PROCESSES 4 Company Confidential VDL ETG Core Technology Markets Semiconductor Capital Equipment Turn Key Projects Analytical Equipment Led Manufacturing Equipment Medical Equipment Solar Production Equipment Science & Technology Is a technology driver for our main stream business Benefits from our expertise in manufacturing and assembly for series manufacturing Focus of employing core technologies to : Free Electron lasers and CLIC Optical modules for instruments. Company Confidential VDL ETG Added Values for S&T Time to market • Co-development & rapid proto typing • Increased complexity requires higher level outsourcing CLIC (future): from cell over bonding to (ultimately) complete module EUV light source : from idea to product in 1 year Industrialization • Early customer involvement - cost control & risk reduction • Co / Redesign for manufacturability Second Harmonic Output Cavity Redesign for manufacturability, assembly and tuning with a cost optimization by reduction of the nr of parts from 21 to 12 and the nr of brazing steps from 3 to 2 Company Confidential Mirror base module for ELT : weight reduction of 100 kg per module (1000 modules needed) Examples of best practices X-band structures for CLIC PETS HP loads …. BOC Pulse compressor J-Couplers for SwissFEL SwissFEL structures RF Gun CCL Accelerating Structures Matisse mirrors for the VLT RF Hybrid Blocks (163–211GHz) for ALMA Telescopes Breadboard with optics for TMA nano satellite Mount for the Sentinel 5 Spectrometer Company Confidential Plans for the future - Strengthening our capabilities Parts manufacturing Industrializing machining process Integrating quality control Assembly & test Strengthening our capabilities on • E-beam welding • Etching • Out baking Building up experience on • H2 bonding • RF testing Capability reinforcement needs to be done with (international) partners in academia and industry. Company Confidential Plans for the future - Targeting new markets for X-band Using X-band normal conducting accelerators opens new perspective on market drivers Increased field strengths / gradients Ability to scale down Cost of ownership • Reliability (using C&S-band frequencies and parts with X-band specifications) • Life Time (using C&S band frequencies and parts with X-band specifications) • Infrastructure (less energy & no cryogenic infrastructure required) Plan to address the potential markets Intensifying the relationship with our technology partners and capitalizing our common knowledge and (future) experiences in X-band Identifying accelerator applications Building up expertise teams on commercial applications for X-band Company Confidential Applications divided into particle type Accelerators Proton Electron Low energy application (large market) Material treatment (existing / growing market) Tumor treatment ) Tumor treatment (small but growing market) (proof-of-concept) Materials Research Material treatment (small market) (growing market) Materials and biological research Proton beam lithography Fundamental research (growing market) (ideas) Light source lithography Fundamental research (ideas) (niche market) Generating radiation Free Electron Laser Collision with target to generate X-Ray wide range of wavelengths (existing and large market) (growing market) E-beam Welding X-ray imaging (growing market) (large market) Other elements SEM/ TEM Tumor treatment (existing market) (large market) Fundamental research Sterilization Defense (USA) (niche market) (existing / growing market) (ideas) (niche market) Potential for compact accelerator Security Fundamental research (proof of concept) (niche market) Company Confidential Applications : Proton therapy First commercial linear accelerator application for VDL ETG LIGHT (Linac for Image Guided Hadron Therapy) developed by ADAM VDL ETG is partner to manufacture., build and test the CCL Accelerating modules First module delivered for high power test (Low power RF and bead pull test done @ VDL) VDL ETG was responsible for Manufacturing redesign Parts manufacturing Assembly and brazing Company Confidential Applications : ART*LIGHT Synchrotron research for art and archaeology Varnishes on musical instruments Bones Painting alterations Courtesy of the Mary Rose Trust. Conservation wreck of warship Glasses decoration Company Confidential Applications : ART*LIGHT Synchrotrons... High brilliance BUT: Accessibility High energy x-rays Beam time Coherent Available space Variable energy Beam intensity Elemental, molecular & structural characterization Imaging with micron resolution The most powerful non-destructive diagnostic tool Company Confidential Applications : ART*LIGHT A Dutch Tabletop Synchrotron for Conservation Research Compton Back Scattering source A compact synchrotron-like light source inside the museum! 4m ART*LIGHT will change the way we look at art Company Confidential Looking back Long standing supplier of CLIC prototype parts (since 1989) circa 1994 2008 Evolution of requirements • 30 mm disks • circular iris • no waveguides 1990’s • 80 mm disks • elliptical iris • closed waveguides 2000’s Company Confidential • Higher demands on surface finish and flatness due to shift from brazing to bonding • Open waveguides 2010’s Looking back VDL ETG is involved in CLIC for Technology push for machining capabilities Business potential in CLIC and related applications CLIAPSI Company Confidential SwissFEL Looking back – and ahead VDL ETG is involved in CLIC for Technology push for machining capabilities Business potential in CLIC and related applications Company Confidential SwissFEL and AVO Cost study Based on the experienced gained in the small series production a study was carried out focused on: Engineering design: cost driving areas and proposals for a significant saving; Tolerances, Ra, flatness: identification of the areas where a relaxation of the requirements would lead to a cost saving; Technologies: final machining is the costly operation; which specification could allow switching from Ultra Precision to High Precision machining. Pre machining • Sawing • Turning • Pre-milling • Drilling tuning holes • Measurement • Annealing End machining • Fly cutting • End milling • Turning side waveguides • Turning opposite side • Metrology • Cleaning & inspection 18 Standard manufacturing flow Company Confidential Cost study – breakdown per manufacturing step Item Tooling 6.9% Stage Operation Turning tool - Turning PT Mill - Milling PT Diamond mill - Milling UPT Diamond tool - Turning UPT Manufacturing step Work preparation PT / HPT Programming PT / HPT Sawing Pre machining Turning PT 12.7% Drilling Milling PT Annealing Metrology PT - HPT Work preparation UPT Programming UPT Flycutting End machining Milling UPT 79.7% Turning UPT Cleaning Metrology UPT Cost 0.6% 0.5% 3.4% 2.4% Cost 1.2% 1.4% 0.6% 2.7% 1.9% 2.8% 0.5% 1.5% 1.2% 2.2% 3.5% 35.4% 27.3% 1.1% 9.0% 19 Company Confidential Cost study – Cost down 2011 2013 Cost level down from 100% to 86% (2011 to 2013) Actions taken for : Use of adapted tooling in pre-machining Pallet machining & 2 different zones for diamond milling Reduction of end metrology by on machine measurements Highest cost remain in end machining Diamond milling Diamond turning End metrology (35% of 2013 cost level) (27% of 2013 cost level) (9% of 2013 cost level) 20 Company Confidential Cost study – Cost reductions Current cost drivers are identified – some changes are already implemented 2 zones (profile accuracy of 4 μm in zone A and 20 μm in zone B) Reduction of the nr end measurements Possible cost reductions Increase of series size as large(r) series will significantly reduce manufacturing costs Remaining at UPT-machining • Design change from corner radii (rr) from 0.5 mm to 2.5 mm • Relaxation of surface finish on o side walls of wave guide o bonding face(s) o Iris • Dedicated UPT machines Switch to HPT-machining 21 Company Confidential Cost study – Cost reductions dedicated UPT-machine Parts to be machined based upon CLEX-structure Investigation was started with LT Ultra following 2 different approaches : Single disk UPT machine All machining operations done in one setup Small strokes high accelerations short manufacturing times 1 disk per manufacturing step frequent handling (operator or robot) Automation possible ? Multiple disk UPT machine All machining operations on multiple discs in one setup Larger moving masses lower accelerations longer machining times Multiple disks per machining step less handling Complex machine (multiple C-axes) Can be based up on current milling machine (already capable of disc machining / part metrology and pallet machining implemented) Company Confidential 22 Cost study – Cost reductions Switch to HPT-machining Main differences between UPT and HPT machining are: Higher feed rates at HPT machining RPM of milling spindles is currently the limiting factor Higher power and torque of axes allow higher material removal rates can introduce stresses and sub surface damages (max 10 % of cutting depth) Better lubrication using spray lubrication in stead of mist risk for contamination of parts HPT machining is an industrial technology with a higher level of automation can be developed / further optimized for UPT machining Machine prices are comparable, perhaps even higher for HPT machines CLIC Matrix build based upon profile accuracy of RFzones (iris and waveguides) and surface finish. significant tolerance relaxations needed Without significant relaxations on both tolerances and RF-specifications HPTmachining will have no advantages to UPT-machining Company Confidential 23 Ambitions : from CLIC Disc to 2 Beam Module for CLIC CLIC-disc • O₂-free Copper • Ultra Precision Accelerator Structure • H₂ - bonding • Ultra Clean RF-unit • E-beam welding • Testing 2Beam Module • Tenderable TPD • Final Assy & Test CLIC 24 Company Confidential Summary As VLD ETG we gained a lot of experience over the last decades Are at a standstill with a risk of expertise loss Gaps are (partially) filled with CLIC-related projects Cost reductions are realistic (and identified) but require : Higher volumes and the related dedicated equipment A specification relaxation (if possible) We are ready for volume production and higher level assembly CERN : We want you to challenge us. 25 Company Confidential Enabling your success in business... Company Confidential Company Confidential