Preparing a Coating Inspection Plan

advertisement

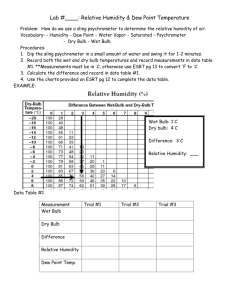

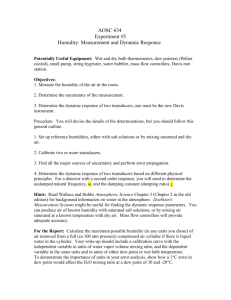

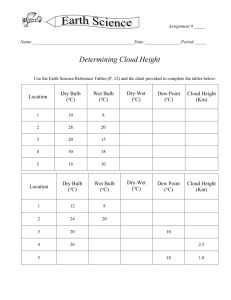

Monitoring Environmental Conditions for Cleaning & Painting Operations William D. Corbett KTA-Tator, Inc. Introduction • Webinar Content: Overview of Commonly Monitored Conditions during Surface Preparation Overview of Commonly Monitored Conditions during Coating Work Instrumentation for Measuring Environmental Conditions Documentation of Conditions Determining Conformance to Project Specifications and/or Manufacturer’s PDS Location and Frequency of Data Acquisition Altering the Environment to Achieve Conformance Learning Objectives/Outcomes • Completion of this webinar will enable the participant to: Describe the environmental conditions commonly monitored during surface preparation and coating work Describe the instrumentation that is commonly used to measure environmental conditions Document environmental conditions Compare on-site conditions to specification requirements Describe the frequency and location of measurements Describe methods for altering the environment to attain conforming conditions Definitions • Air Temperature (Ta) • Wet Bulb Temperature (Tw) • Depression of Wet Bulb Temperature from Dry Bulb Temperature (Ta-Tw) • Relative Humidity (RH) • Dew Point Temperature (Td) • Surface Temperature (Ts) Definitions • Air Temperature (Ta): Temperature of the surrounding air • Wet Bulb Temperature (Tw): A measurement of the latent heat loss caused by water evaporation from a wetted sock on the end of a bulb thermometer in a psychrometer • Depression of Wet Bulb Temperature from Dry Bulb Temperature (Ta-Tw): The calculated difference between the air temperature and the wet bulb temperature Definitions • Relative Humidity (RH): The percentage of moisture or water vapor in the air, relative to the maximum attainable at the same temperature • Dew Point Temperature (Td): The temperature at which condensation of water vapor occurs on a surface • Surface Temperature (Ts): The temperature of the surface to be prepared and coated Converting Temperature Temperature expressed in Celsius or Fahrenheit Celsius – Freezing is 0; boiling is 100 Fahrenheit – Freezing is 32; boiling is 212 Converting Temperature Converting Fahrenheit to Celsius oC = (oF-32oF) ÷ 1.8 Example: (83oF-32oF) ÷ 1.8 = 28.3oC Converting Celsius to Fahrenheit oF = (1.8 x oC) + 32oF Example: (1.8 x 5oC) + 32oF = 41oF Environmental Conditions for Surface Preparation “Rough” surface preparation work can occur when conditions are less than desirable (unless prohibited by contract) “Final” surface preparation work should occur when conditions preclude moisture formation on prepared surfaces Measuring Ambient Conditions Prior to Final Surface Preparation • If air temperature and relative humidity are such that moisture from the air condenses on the surface, the surface may rust bloom, or rust back prior to coating • Recommend verifying that the temperature of the surface is at least 5°F (3°C) higher than the dew point temperature to preclude condensation (requirement may be invoked by specification) Significance of 5°F (3°C) • Theoretically, a small (<1°F) increase (surface temperature over dew point) will preclude moisture formation • Minimum increase of 5°F (3°C) compensates for: Instrument tolerances Varying conditions Changing conditions Environmental Conditions for Coating Application • Air Temperature (min. & max.) • Relative Humidity (min. or max) • Dew Point Temperature • Surface Temperature [min. 5 °F (3°C)] above Dew Point Temperature • Wind Speed (max.) Significance of Conditions • Air Temperature Too cold or too hot can affect coating application & curing • Relative Humidity Too damp or too dry can affect coating application & curing • Surface Temperature Too cold or too hot can affect application & curing • Surface temperature at or below dew point temperature will result in condensation Significance of Conditions, con’t. • Wind Speed Too windy can affect application (dry spray) and cause overspray damage • Mixing/application of coatings under adverse weather conditions can void the manufacturer’s warranty and is considered a specification non-conformance History of Environmental Condition Measurement • Whirling apparatus containing wet & dry bulb thermometers developed in the 1600’s We’ve Come A Long Way Baby! • Use of Sling psychrometers to obtain dry bulb/wet bulb measurements is still mainstream • Electronic measurement is possible • Some electronic psychrometers adversely affected by “outdoor” conditions Ambient Conditions & Surface Temperature • Measuring Instruments Sling Psychrometers* Battery-powered Psychrometers* Electronic Psychrometers Analog, Thermocoupletype & Non-contact Surface Thermometers * Used in conjunction with psychrometric charts or calculators Sling Psychrometer Using Sling Psychrometers • ASTM E337 • Verify wick cleanliness • Saturate wick and/or fill reservoir with DI water • Whirl 20-30 second intervals until wet bulb stabilizes (2 readings within 0.5o) • Record wet & dry bulb temperatures Using Battery-Powered Psychrometers • • • • ASTM E337 Verify wick cleanliness Saturate wick Operate until wet bulb stabilizes (2 readings within 0.5o; typically 2 minutes) • Record wet & dry bulb temperatures Using Psychrometric Charts • Locate Chart (relative humidity or dew point) • Verify Barometric Pressure (e.g., 30.0 in.) • Intersect air temperature with wet bulb depression (Ta-Tw) Determining Dew Point Temperature Example: Air temperature: 60°F Depression wet bulb thermometer: 5°F Dew Point temperature: 51°F Determining Relative Humidity Example: Air temperature: 60°F Depression wet bulb thermometer: 5°F Relative Humidity: 73% Relative Humidity and Dew Point Calculators 1. 2. 3. 4. 5. Convert oF to oC using right “window” Align dry bulb & wet bulb temperatures (top of calculator) Read Dew Point from upper “window” Align dry bulb & dew point temperature (bottom of calculator) Read %RH from lower “window” 2, 3 1 4, 5 Using the Psychrometer Slide Scale • Intersect air temperature and wet bulb temperature • Base of “Y” points to relative humidity • Cannot determine dew point temperature • White ink fades over time/usage (left image) Electronic Psychrometers • Measure/Record: Air Temperature Surface Temperature (ST) Relative Humidity Dew Point Temperature (DP) Spread between DP and ST • Features Auto-logging allows for automatic data collection Magnetic surface probe Data graphing and uploading using software Audio/visual alarm Electronic Psychrometers • Measure/Record: Air Temperature Surface Temperature (ST) Relative Humidity Dew Point Temperature (DP) Spread between DP and ST • Features Auto-logging Integral magnets Data uploading using software Audio/visual alarm BlueTooth® Data Output Another model (right) offers infrared surface temperature Measuring Surface Temperature • Dial-Type Thermometer Position & stabilize for minimum of 2 minutes • Thermocouple-Type Thermometers Stabilize quickly • Infrared (non-contact) thermometers Watch distance Assessing Wind Speed • Analog wind meters • Digital wind meters • Rotating Vane Anemometers Air flow inside containment Wind speed Documenting Ambient Conditions and Surface Temperature Condition Data Date 2/23/11 Time 1300 hours Dry Bulb Temperature (DB) 16oC (60oF) Wet Bulb Temperature (WB) 13oC (55oF) Depression (DB-WB) Relative Humidity 3oC (5oF) 73% Dew Point Temperature 11oC (51oF) Surface Temperature 15oC (59oF) Wind Speed Measurement Location 11 km/Hr (7 mph) West side of tank, ground level Verification of Accuracy Thermometers • ASTM E 337 • Remove wick from thermometer • Compare dry & wet bulb temperatures quarterly • Compare thermometers to a traceable thermometer in controlled environment at minimum of 4 temperatures annually Calibration of Electronic Psychrometers • Some manufacturers provide “Calibration Kits” Used to verify accuracy only • Annual calibration by the manufacturer or approved laboratory recommended Verification of Accuracy – Surface Thermometers • No “Standard” method • Equipment manufacturers provide instruction • Surface probes integral to electronic psychrometers are calibrated by the manufacturer • Compare thermometers to “Traceable” thermometer in controlled environment Determining Conformance to Project Specifications • Compare actual conditions to project specification requirements • Example: Air temperature: 50-110oF Relative humidity: < 85% Surface temperature: 50120oF and a minimum of 5oF higher than dew point temperature Wind speed: < 15 mph Determining Conformance to Product Data Sheets • Compare actual conditions to manufacturer’s recommendations • Example: Air temperature: 35-110oF Relative humidity: < 95% Surface temperature: 35120oF and a minimum of 5oF higher than dew point temperature Wind speed: Typically not addressed Location and Frequency of Data Acquisition • Location Dictated by where the work is being performed (e.g., inside vs. outside of a containment; balcony of elevated storage tank vs. ground level) If interior, with ventilation in operation Shops: Blast or Paint bay area • Frequency Prior to final surface preparation Prior to mixing of coatings Four-hour data collection intervals is common More frequent measurement if conditions are changing Achieving Conditions by Changing the Environment • Heat • Dehumidification • Humidification Achieving Conditions by Changing the Environment • Heat Achieve & maintain temperature during application & cure Indirect fired propane AC powered equipment with thermostatic controls Ventilation to exhaust solvent vapors is critical Dehumidification • Dehumidification (DH) equipment removes air moisture, reducing opportunity for condensation • Conditions monitored using computer software (component to DH equipment) or by manual measurements • SSPC/NACE Joint Technical Report – SSPC-TR3/NACE 6A192, “Dehumidification and Temperature Control During Surface Preparation, Application and Curing for Coatings/Linings of Steel Tanks, Vessels and other Enclosed Spaces” Dehumidification, con’t. • DH accomplished by: Compression Refrigeration Desiccation (liquid or solid sorption) Combination of methods listed Refrigeration and desiccation (solid sorption) most common for field work Dehumidification, con’t. • Refrigeration Air cooled over refrigeration coils Condensation occurs on coils and is collected Dry air exits the DH system (at reduced temperature, humidity and dew point) Source: SSPC-TR3/NACE 6A192 Dehumidification, con’t. • Desiccant Air passed over/through granular beds or fixed desiccant structures Desiccant (silica gel or lithium chloride) is active and dehydrated (low vapor pressure) Desiccant absorbs moisture from air. Hydration reaction causes exothermic reaction (heated air), so may be used with refrigerationtype DH Source: SSPC-TR3/NACE 6A192 Achieving Conditions by Changing the Environment • Humidification May be required for moisture cure coatings Moisture generated by wetting down floors or dampening the applied coating after initial drying Summary • During this webinar, we have: Reviewed commonly monitored conditions during surface preparation and coating work Described the instrumentation used to measure environmental conditions, including methods of calibration and accuracy verification Illustrated documentation procedures Described the importance of determining conformance to project specifications and/or manufacturer’s PDS Described the location and frequency of data acquisition Described three methods to altering the environment, in order to achieve conformance Monitoring Environmental Conditions for Cleaning & Painting Operations THE END