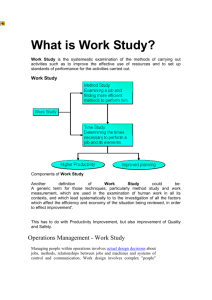

Method study

advertisement

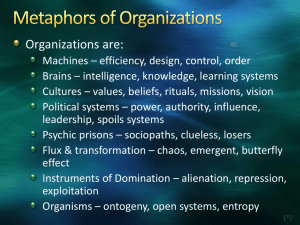

Presentation Topic Daffodil International University Department of Textile Engineering Introduction Work-study forms the basis for work system design. The purpose of work design is to identify the most effective means of achieving necessary functions. This work-study aims at improving the existing and proposed ways of doing work and establishing standard times for work performance. “The greatest production results when each worker is given a definite task to be performed in a definite time in a definite manner.” – Dr. Frederick W. Taylor Work study Work Study is the systematic examination of the methods of carrying out activities such as to improve the effective use of resources and to set up standards of performance for the activities carried out. According to the ILO Hand Book, it is a term used to embrace the techniques of method study and work measurement, which are employed to ensure the best possible use of human and material resources in carrying out a specified activity. History of Work-study in Bangladesh Mr. F W Taylor who is called the father of scientific management is the founder of work-study. During the Second World War USA needed so many arms within a short time. Then Mr. F W Taylor applied Work-Study method to make many arms in short time & go tremendous result. After that work-study is being used in everywhere. Now it‘s circumference is getting larger day by day. Mr. Keith Harding form England started Work-Study in Bangladesh (Young one Corporation) in 1991.Now it is contributing very well to increase the productivity in Bangladesh. Objectives of work study: To analyze the present method of doing a job, systematically in order to develop a new and better method. To measure the work content of a job by measuring the time required to do the job for a qualified worker and hence to establish standard time. To increase the productivity by ensuring the best possible use of human, machine and material resources and to achieve best quality product/ service at minimum possible cost. To improve operational efficiency. To develop plant safety schemes, equipment utilization, plant layout, and conducive work environment. To utilize optimum use of plant, equipment, manpower and material. Techniques of work study and their relationship… The term "work study" embraces several techniques, but in particular method study and work measurement. Method study is the systematic recording and critical examination of ways of doing things in order to make improvements. Work measurement is the application of techniques designed to establish the time for a qualified worker to carry out a task at a defined rate of working. Method study and work measurement are, therefore, closely linked. Method study is concerned with the reduction of the work content of a job or operation, while work measurement is mostly concerned with the investigation and of any ineffective time associated with it; Techniques of work study and their relationship Basic procedure of work study… Basic procedure of work study… There are eight steps in performing a complete work study. They are: 1. Select the job or process to be studied. 2. Record or collect all relevant data about the job or process, using the most suitable data collection techniques, so that the data will be in the most convenient form to be analyzed. 3. Examine the recorded facts critically and challenge everything that is done, considering in turn: the purpose of the activity; the place where it is performed; the sequence in which it is done; the person who is doing it; the means by which it is done. 4. Develop the most economic method, taking into account all the circumstances and drawing as appropriate on various production management techniques , as well as on the contributions of managers, supervisors, workers and other specialists with whom new approaches should be explored and discussed. Basic procedure of work study 5. Evaluate the results attained by the improved method compared with the quantity of work involved and calculate a standard time for it. 6. Define the new method and the related time and present it to all those concerned, either verbally or in writing, using demonstrations. 7. Install the new method, training those involved, as an agreed practice with the allotted time of operation. 8. Maintain the new standard practice by monitoring the results and comparing them with the original targets. Steps 1, 2 and 3 occur in every study, whether the technique being used is method study or work measurement. Step 4 is part of method study practice, while step 5 calls for the use of work measurement. Operations Management-Work Study… Managing people within operations involves actual design decisions about jobs, methods, relationships between jobs and machines and systems of control and communication. Work design involves complex "people" relationships between operative staff, supervisors and specialists e.g. engineering managers and staff who commission new machines and maintain them. People are not mere extensions to machines or horsepower to be switched on and off. A worker's performance may be better than a machine's capability - yet a machine may outstrip the human being for many tasks. People can be hurt/injured physically by operating environments or trapped socially and psychologically in them/by them. How operational systems are designed and the jobs and performance relationships within them are of great operational, economic and social importance. In this context then work study is --“A collection of techniques used to examine work - what is done and how it is done - so that there is systematic analysis of all the elements, factors, resources and relationships affecting the efficiency and effectiveness of the work being studied.” Operations Management-Work Study In the Path of F. W. Taylor: Method study and work measurement are two principal activities of work study which originated in the work of F. W. Taylor. FW's "scientific management" imperatives are: Investigate the work situation and identify weaknesses - where and why is poor performance happening? The "scientific" title for this approach to management means placing emphasis on data gathering and rational analysis . Certain narrow assumptions about the objectivity of efficiency criteria. The existence of direct, deterministic relationships between worker performance and incentive payments. Consideration of the worker to some extent as a machine. Thus we can evaluate and introduce improvements in operating methods. We can select staff with characteristics that fit the job, train and reward them using payment schemes the offer particular economic incentive by linking payment to measured performance. Methods study Approach Method study is an analysis of ways of doing work. The mnemonic SREDIM (a common-sense heuristic or general problem solving strategy) represents the method study stages i. Select the tasks to study ii. Record the facts about it iii. Examine these iv. Develop a new method v. Install/implement it vi. Maintain it Work Measurement Approach Work measurement involves assessing the time a job should take to do. Similar steps are involved as to method study. i. Select the tasks ii. Record the facts iii. Analyze them iv. Calculate basic and standard times for the task v. Agree the method and its related time Work measurement offers the answers of the following questions: “How many extra hours/people are needed? Why? What will the new method offer? Is it possible to change methods? What will be the costs/benefits?” Efficiency Indices Using data on measured work, unmeasured work and idle time we can Attempt to derive effectiveness indices. Constable and New exemplify efficiency and effectiveness indices. A. Efficiency While performing measured work (ratio of standard/measured hours of Work produced and the actual time taken) B. Effectiveness Which Includes Accounting for work done for which no measured time Exists. Such work is typically paid for by an agreed hourly/day rate. Of course a supervisor may pass a judgment or state that the amount of work and its quality are inadequate. Recognition of possible idle time caused e.g. by management not allocating any work, supplier/materials delays, machine breakdowns etc. Benefits of work study… Increased productivity and operational efficiency. Reduced manufacturing costs. Improved work place layout. Better manpower planning and capacity planning. Fair wages to employees. Better working conditions to employees. Improved work flow. Reduced material handling costs. Benefits of work study Provides a standard of performance to measure labor efficiency. Better industrial relations and employee morale. Basis for sound incentive scheme. Provides better job satisfaction to employees. Concerned with the systematic analysis and improvement of manually controlled work situations.