Facility Location Decisions - The University of Texas at Dallas

advertisement

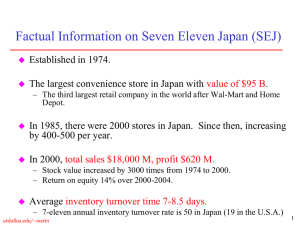

SC Design Facility Location Strategy utdallas.edu/~metin 1 Frequency Decomposition SCs are enormous It is hard to make all decisions at once Integration by smart decomposition Frequency decomposition yields several sets of decisions such that each set is integrated within itself utdallas.edu/~metin 2 Frequency Decomposition Low frequency activity, ~ once a year, high fixed cost – R&D budget – Capacity expansion budget Moderate frequency activity, ~ once a month – Cancellation of specific R&D projects depending on experimental outcomes – Specific machines to purchase High frequency activity, ~ once a day, low fixed cost – What experiments to start / continue today – What to produce utdallas.edu/~metin 3 Facility Location: The Cost-Response Time Frontier An inventory location based point of view 7-Eleven Regional Hi Local Finished Goods (FG) Inventory Regional FG Inventory Cost Local WIP (work-in-process) Central Sam’s Club Central FG Inventory Central WIP Central Raw Material and Custom production Custom production with raw material at suppliers Low Pull the inventory upstream Low utdallas.edu/~metin Response Time Hi 4 Where inventory needs to be for a one week order response time - typical results --> 1 DC Customer DC utdallas.edu/~metin 5 3 day order response time - typical results -> 5 DCs Customer DC utdallas.edu/~metin 6 Same day / next day order response time typical results --> 26 DCs Customer DC utdallas.edu/~metin 7 Inbound and outbound shipping with more facilities Supplier Add more facilities for responsiveness Manufacturer Inbound shipment Supplier Manufacturer Customer Outbound shipment Distributor Inbound shipment Retailer Customer Outbound shipment More inbound shipping and less outbound shipping with more facilities. Less (inbound + outbound) shipping costs with more facilities possible, if economies of scale in transportation. utdallas.edu/~metin 8 Costs and Number of Facilities Total SC Inventory Facility costs Costs Transportation Number of facilities No economies of scale in shipment size, SC covers a larger portion with each facility. With economies of scale in inbound shipping to retailers. utdallas.edu/~metin 9 Cost Build-up as a function of facilities Cost of Operations Total Costs Facilities Inventory Transportation Labor Number of Facilities utdallas.edu/~metin 10 Classification of Network Design Decisions Facility function: Plant, DC, Warehouse: What facility performs what function – Packaging at the manufacturer or warehouse – Should a rental computer return location run diagnostic tests on the returned computers or should the testing be done at major warehouses? Question arising from CRU Computer Rental Case done in OPRE6302 Facility location – Starbucks opened up at UTD student apartments in 2005 but closed in 2006! – Recall Japanese 7-eleven and their blanketing strategy – SMU’s experimentation with Plano campus: http://www.smu.edu/legacy . Capacity allocation – SOM car park took 80 cars in 2005 and expanded in 2006 to take about 110 cars, further expanded in 2009 to take about 300 cars. Supply and market allocation: Who serves whom – By location: UT Austin serves central Texas students – By grade: UT Arlington serves undergraduate students utdallas.edu/~metin 11 Strategic Factors Influencing Location Decisions Strategic Facilities Lead facility Global Customers Regional Customers Server <local-content> Offshore <reduced tariffs> <for exports> VW plants in Mexico Serving Latin America utdallas.edu/~metin Suziki’s Indian venture Maruti Udyog Source <low-cost> Nike plants in Korea <advanced technology> Lockheed Martin’s JSF in Dallas Outpost facility <Learn local skills> Facilities in Japan; Toyota Prius Contributor <customization> <development skills> Maruti Udyog 12 Factors Influencing Location Decisions Customer response time and local presence Operating costs – main driver for offshoring Technological, – Availability and economies of scale (fixed operational costs) » Infrastructure, electricity, phone lines, suppliers Macroeconomic / Politic – – – Semiconductor manufacturing takes place only in 5-6 countries worldwide Tariffs, exchange rate volatility, economic volatility Economic communities: Nafta, EU, Pacific Rim, Efta Stability Logistics and facility costs Competitive – Positive externalities » Nissan in India develops car suppliers which can also supply Suziki in India. » DFW Telecom corridor hosting Alcatel, Ericsson, Nortel, … » Toyota City, Shopping Malls – Negative externalities, see the next slide utdallas.edu/~metin 13 Negative externality: Market Splitting by Hotelling’s Model 0 a a b 1-a-b 1 b Suppose customers (preferences, e.g. sugar content in coke) are uniformly distributed over [0,1] - How much does firm at a get, how about firm at b by locating as above? - If a locates first, where should b locate? - If a estimates how b will locate in response to a’s location, where should a locate? utdallas.edu/~metin 14 Steps of Comparing Locations According to McKinsey Global Institute on HBR Jun. 2006 p.91 1. Draw up a list of possible locations 2. Define the decision criteria – Six common criteria used by companies » » » » » » 1. Cost of operating – tax incentives from local/federal governments 2. Availability of the skills 3. Sales potential in the adjacent markets 4. Risk of doing the business 5. Attractiveness of living environments 6. Quality of infrastructure 3. Collect data for each location 4. Weight the criteria » Fortisbank of Belgium, wants to enter new large markets, gives highest weight to 3. » Citibank, wants a location for a captive IT center, gives the highest weight to 4. Find risk data at – Economist intelligence unit: www.eiu.com – UN Development Program: http://hdr.undp.org/statistics/data/ 5. Rank locations according to weighted sum of their scores 6. Assess the dynamics of the labor pool utdallas.edu/~metin » Availability of skilled labor: Top tier universities in large U.S. cities (e.g., Dallas?). 15 Summary Frequency decomposition of activities A strategic framework for facility location – Classification – Factors – Steps utdallas.edu/~metin 16