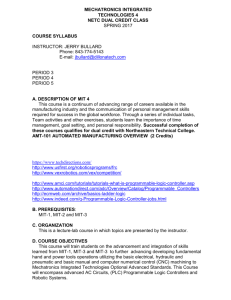

Summary of content

advertisement

LIW 2000 CONTOH MODUL KULIAH MECHATRONICS (Sample Syllabus Document) MECHATRONICS Nominal duration : Module code or number : 38 hours xxxx Module purpose The aim of this module is to further develop student control system and programming skills and knowledge, and enable them to apply their skills in an integrated “Mechatronics” fashion to a range of industrial applications. Relationship to competency standards This module will be modified in line with the requirements of the national metals an Engineering standard when they become available. The module contains the knowledge and skills identified and agreed by the National Assessment Body. It has been developed on the assumption that these will be reflected in future standards. Prerequisites and/or co – requisites Basic Industrial control system and programming Principles Summary of content This module contain: 1. Basic Control System Models Open loop control Close loop control (i.e feedback) Continuous control plans e.g proportional, integral, Derivative, and PID 2. Computer Aided Manufacturing (CIM) and Flexible Manufacturing Systems (FMS) 3. Introduction to number System Binary Binary Coded Decimal ( BCD ) Octal / Hexadecimal – ASCII 4. Introduction to Logic System Logic Gates Logic gate circuits Truth tables Contoh modul kuliah mechatronics __ 1 LIW 2000 5. Programmable Controller Applications Sequential Control/Timers/Counters revision Master Control Relays and Jump Commands ( program branching ) Data Registers and data handing 6. Direct Computer Control Signal Conditioning Programming and control applications Delivery For consolidation, the material in this module should be linked with, and complemented by, relevant on job skill practice or other equivalent experience. A suggested program for learning strategies is given below: Learning outcome 1 4 hours Learning outcome 2 4 hours Learning outcome 3 4 hours Learning outcome 4 4 hours Learning outcome 5 16 hours Learning outcome 6 6 hours Since this module has a large “hands on” component, when student spend most of the class time actually programming a testing the PLCs and PCs( at their own speed ) the predominant teaching/learning strategy should be self paced. An industry visit is recommended to show PLC control applications and installation“ at work “ To ensure that the successful operation of student ‘PLC’ and PC programs is essential their own work, it is recommended that “ group work “ be discourage at this point. Also, it is important that PLC simulator units are available for each of the students. Learning Outcomes On completion of this module the learner will be able to: Learning Outcome 1 Briefly describe the basic control system models and given typical examples. Compare the continuous control plans of proportional, integral and derivative in terms of system response to an external disturbance. Assessment Criteria Differentiate between open and closed loop control Compare Feed – forward and Feed – back control systems and give examples. Define and relate the terms: error signal, measured, value, and set point, by giving examples of their application in industrial control system with proportional, integral, derivative, and PID control. Contoh modul kuliah mechatronics __ 2 LIW 2000 Conditions Assessment method Written short answer test or assignment Learning outcome 2 Recognise that Computer Integrated Manufacturing (CIM) is a high level application of the control System models given above that is concerned with the flow and integration of information or data. Describe basic Flexible Manufacturing System (FMS) and explain how this relates to CIM and Mechatronic Assessment criteria Describe what the terms CIM and FMS mean Sketch two different CIM and FMS system block diagrams. Fully label the sketches. List the six component technologies of CIM. Brief describe the function of each component. List four ( 4 ) benefits of three ( 3 ) obstacles and give reasons for these. Conditions Assessment method Short written report/test including diagrams Learning outcomes 3 & 4 Recognise the need for the number System used in computers for modem manufacturing. Convert numbers from decimal to binary, octal, hexadecimal, and binary coded decimal (BDC). Also be able to convert in the reverse direction. Use the ASCII code to convert characters to binary numbers. Solve simple Logic Crate circuits by using Truth Tables. Assessment criteria Convert a range of number between the following forms : Binary, BDC, Octal, Hexadecimal, and Decimal. Write a simple and short alphanumeric message in binary form by using the ASCII code. Repeat the message in Hexadecimal. Solve simple logic gate circuit exercises by using truth tables for the following gates : - And, or, Nand, Nor, Exclusive, Or, Inverter. Conditions Assessment method Program a programmable controller then document and test the program for a range of basic industrial application covering sequential operations including timers and counters, program branching and data handling. Contoh modul kuliah mechatronics __ 3 LIW 2000 Program a programmable controller to control a simple pneumatic circuit and then test and de-bug the program. Assessment Criteria By designing Ladder Logic Diagrams and converting to list form, program a PLC Simulator Unit for a range a basic industrial control problems including : Sequential operations using timers and counters; Program branching using timers and counters; Program branching using Master Control Relay and Jump Instruction. And programs involving data registers and data handling. This the programs using the simulator and, when debugged, show the teacher / instructor the result. For at least two (2) of the above control problems use PC “ On Screen “ PLC programming software to generate the ladder diagrams. Produce a report on each problem consisting of the ladder diagram and the list statements. Label all the contacts and coils used and include explanatory (software generated) comments between ladder rungs to explain how the program operates. Program a PLC to control the operation of a simple pneumatic circuit (or equivalent). De–bug the program and show the teacher/instructor the resulting operation. Conditions Assessment method Programming assignment Practical exercise Learning outcome 6 Explain the need and the method used, for signal conditioning when using a personal computer for machine control application. Program a personal computer using a proprietary programming language (eg BASIC, TURBO PASCAL) to control a simple pneumatic circuit and the test and debug the program. Assessment criteria Program a personal computer to control the operation of a simple pneumatic circuit ( or equivalent). De – bug the program arid show the teacher/instructor the resulting operation. For the practical exercise above, describe the need for, and function of, the latching I/O caned, the Opto-isolated input card and the relay output card. Contoh modul kuliah mechatronics __ 4 LIW 2000 Conditions Assessment method Programming and practical exercise Suggested learning resources Physical resources The following equipment list is suggested for a class of twelve ( 12 ) students. Twelve (12) programmable controllers (PLCs) complete with simulators for testing purposes. Market entry “shoebox” type with 20 I/O, built in 24V DC input power supply, sink input (ie PNP open collector transistor type) and reply outputs. A typical example here is Mitsubishi’s F1-20MRES . The simulator unit (hardware to the PLC), should have momentary push buttons for the first two outputs, and SPST toggle switches for the remaining input. The switches should be labelled to avoid confusion. The output LEDs on the PLC output module should be sufficient to show tested program operation. Six (6) pocket programmers to suit above PLCs. Six (6) personal computer (PC) software programming “ Kits” consisting of software and manuals, plus PLC to PC interface units and cables. Mitsubishi’s “ Medoc” software is a typical example. Six (6) 80386SX, 1Mb RAM, 40Nfb HD, VGA Personal Computers (PC). These are for PLC programming monitoring and documentation, plus the direct computer control exercises. Six (6) copies of programming software and manuals such as BASIC or TURBO PASCAL – required for direct computer control. Six (6) latching I/O cards for insertion in the PC motherboard. An example is Boston Technology’s PC-36 card based on Intel’s 8255 microprocessor chip. Six (6) optical-isolator input cards. These would be mounted externally to the PC and can also be supplied by (amongst others) Boston Technology. Six (6) relay output cards. Also connected externally and supplied by Boston Technology. A basic range of small pneumatic cylinders (eg 20NB x 100 stroke complete with reed switches at each stroke end), solenoid control valves (single and doubles, with 12V or 24V solenoids), flow control valves, quick-connect couplers, air-service units, distributors and lengths of plastic air lines. SMC or FESTO can supply suitable equipment. This equipment is required for the programming/connection exercises using the PLCs and later the PCs. Finally, all the “normal” classroom facilities are required, such as a whiteboard, overhead projector and screen, plus video replay facilities. Contoh modul kuliah mechatronics __ 5 LIW 2000 Note: Ideally, all of the above would be supplied by the teaching University. Ensure that all PLC input sensor devices are compatible with the PLCs used. While not essential, the following PLC peripherals could also be used: Digital to Analogue converters High speed counters Position control units Input/Output (I/O) extension units. Texts/references There is no specified textbook for this module, although the following references are recommended: Programmable Controllers – Operation and Application, lan G Warnock, Prentice Hall, 1988. A System Approach to Programmable Controllers, Fred Swainston, Thomas Nelson Australia, 1991. Programmable Logic Controllers and Applications, A Crispin, McGraw Hill, 1990. Their Engineering Programming and operations manuals for the Programmable Controller and Personal Computer peripheral add-on card(s) used. PC programming language manuals/guides such a BASIC, TURBO, PASCAL etc. VHS videos available from associated universities presenting such units as Mechatronics, Flexible Manufacturing System (FMS), Computer Integrated Manufacturing (CIM) and Robotics. Contoh modul kuliah mechatronics __ 6