PPT - 12 MB

advertisement

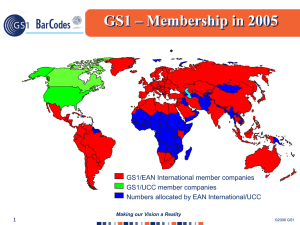

EPC Advanced Business Aspects Training Chapter 1 Introduction Introduction Chapter 1: Chapter 2: Chapter 3: Chapter 4: Chapter 5: Chapter 6: 3 Introduction The Global Vision Benefits of EPC/RFID EPC/RFID Deployment Examples of Applications The Consumer Chapter 2 The Global Vision The Internet of Things The Internet (of information) expands to the real world: an Internet of Things emerges The Internet of Things Internet is an island Today’s Internet is an island in the gulf of physical objects: only connected through human (manual) inputs Benefits of the Internet of Things • Status (capture & report) • Diagnostics (troubleshoot) • Upgrades (augment performance) • Control/Automation (device cooperation) • Profiling/Behaviour Tracking (performance) • Replenishment/commerce (consumption) • Location Mapping and Logistics (sales) Over 100 trillion items per year 10000 bio 6.5 bio 2 bio 1 bio The size of the future market Total number of tags purchased annually (in Millions) 100,000 86,700 80,000 60,000 40,000 20,000 22,400 144 3,220 2007 2012 0 2017 2022 The size of the future market Total number of locations with RFID readers 453,000 500,000 400,000 300,000 200,000 144,000 100,000 2,750 30,710 0 2007 2012 2017 2022 Total number of RFID readers deployed 6,268,500 7,000,000 6,000,000 5,000,000 4,000,000 Available at www.bridge-project.eu 3,000,000 2,000,000 1,000,000 176,280 1,161,800 7,630 0 2007 2012 2017 2022 We only can manage what we can measure. Cost of data entry Information systems & the Internet Punch card Keyboard Manual measuring Barcode UbiComp-Technologies Machine sensing Physical world No measures means potential business problems • Average OOS level in retail industry: 8.3% • Average shrinkage rate for supermarkets/grocery in US: 1.5% of sales • Average deduction level for inaccurate invoices: 9.9% of annual invoiced sales in US • Cost of unsellable food and grocery products in US: 1% of sales • Product counterfeiting is estimated to account for between 5 and 7% of world trade Source: C. Tellkamp, E. Fleisch, Auto-ID Lab St. Gallen Recent advances in miniaturization, sensor & communication technology, and new materials drive for a new computing paradigm Miniaturization and cost reduction (4) Smart Things (3) Mobiles / Smart Cards (2) PCs (1) Mainframe Time The most widely deployed Technology: RFID Leveraging RFID in retail Source: C. Tellkamp, HSG; Gartner The opportunities are multi-fold: Search & Find Trust Linking Information The correct medication to the right patient Smart T-Shirts Anti-counterfeiting solutions are under study STOLPAN Project Retail Back-Office Solution Middleware Middleware Middleware Project Goals: EPC and NFC compatible mobile phones EPC based product information EPC based product authentication NFC based loyalty programs EPC triggered mobile advertisement NFC based self check out and mobile payment Product Info Middleware Loyalty program Credit Card New items are tagged everyday… … for various purposes RFID enables new business models Sensors GPS Risk-based-pricing Source: Courtesy of F. Mattern, ETH Zürich Technology that reaches the consumer Summary 26 Chapter 3 Benefits of EPC / RFID 27 What are standards? Why do we have Standards? Benefits of using standards Benefits of Global Standards Reduce costs Speeds customer acceptance Encourage innovation Reduce complexity Global Standards & Competitive Advantage TDMA CDMA GSM PCS Standards allow technology providers to focus on innovation, not translation and intermediation The role of EPCglobal standards Encourage Technology Innovation Foster competition Guaranteeing Common Interoperability Protocols for exchanging Role of Global information Standards The benefits of EPCglobal standards Encourage Technology Innovation Lower Costs of products and implementation Foster competition Guaranteeing Common Interoperability Protocols for exchanging Benefits of information Global Standards Smooth integration with existing infrastructure Lower Cost of Changes Overview of RFID benefits RFID is a tool allowing Increased Visibility Fully automated data capture Analysis application Best business decisions RFID vs Barcodes Benefits of EPC / RFID over Bar Codes: Attributes EPC / RFID Bar Code Data transmission Electromagnetic / Wireless Optical Reading capability Non-line of sight Line of sight Tag reading Multiple One by one Reading speed 500 / minutes 80 / minutes Moving object reading Data modification Yes No Read & write Write once, read many Data volume 1 bit ~ 16 Mbytes < 100 bytes Access security High Little but possible Anti-collision Possible Not possible Complying with mandates ALE and EPCIS provide increased visibility electric eye conveyor R Enterprise App Data Center Environment EPCIS Edge Environment pallet R “at time T, the association of the following case tags to the following pallet tag was created at palletizer #3, to fulfill order #1234” Palletizer Capture App “between the time the case crossed the two beams at location L, the tag X was read with temperature T” ALE Filtering & Collection Reader Protocol (LLRP) Reader Reader Supply Chain Visibility Inventory Visibility Chain of Custody visibility Visibility of maintenance Visibility of counterfeit products Visibility is only the starting point Trend Analysis Problem Identification ALE EPCIS EPC Readings Operational Performance Management of Solutions Providers Benefits for the producer Visibility of Production Processes Quick reconciliation of shipments Just-in-time production and delivery Benefits for the seller Reduced safety stocks Availability of products Reduced theft Speedy check outs Improved after sales Customer satisfaction Where is my product? Data flow Your product was last seen in Store #23, at 10am Tuesday, during receiving Data flow Summary 48 Back-up Slides 49 Understanding the Financial Aspects • Calculating ROI for implementing EPC / RFID • The checklist below summarizes some of the key financial items time setin upEPC cost:/ RFID implementations •One incurred Recurring cost: RFID reader RFID tags Middleware Maintenance cost for RFID printers hardware & software Networking & cabling Training Enterprise system integration Consulting Training PC BACKUP SLIDE Understanding the Financial Aspects • ROI Calculation Tools Available in the Market • EPC Value Models • Developed by Stanford University, Massachusetts Institute of Technology • (MIT) and EPCglobal US, aimed to identify business issues and drivers • where EPC / RFID is expected to have the greatest impact & quantify • expected value of EPC / RFID implementation. BACKUP SLIDE • URL: • http://www.epcglobalna.org/dnn_epcus/SubscriberTools/Fina ncialPlanning/EPCValueModels/tabid/225/Default.aspx Understanding the Financial Aspects • ROI Calculation Tools Available in the Market (Con’t) • RFID Cost Tutorial • Developed by EPCglobal Inc. is a reference tool for companies planning to • make an investment in RFID technology. EPCglobal recommends that the cost • items, phase structure and timeline presented herein be modified to suit the • specific needs of the organization. BACKUP SLIDE • URL: • http://www.epcglobalinc.org/what/cookbook/chapter2/ Benefits from Future EPC / RFID Trends When RFID technology is commonly used in the future with sensing technologies, some potential use and benefits can be obtained: • Temperature tracking • Humidity monitoring • Tilt indicator • Accelerometer monitoring • Pressure monitoring BACKUP SLIDE Chapter 4 EPC / RFID DEPLOYMENT 54 Introduction 55 Think of a major change Think of any major change that you have seen undertaken in a business…… Launching a new product A new computer system 56 56 Can you think of a major change that has taken place where you work ? A grand new machine installed…….. ©2008 GS1 Preparing the change Changes need: • Planning • Organisation • Collaboration • Purpose • Objectives • Review Use the same common sense approach Don’t leave your brain in the car park just because it’s radio ! 58 58 ©2008 GS1 Business Context 59 Getting The Business Context EPC and RFID implementation is not only about technical aspects EPC and RFID are tools for a business change in your operations. Business processes Are Key EPC / RFID can now impact your business processes PROCESSES ARE KEY Who Will Be Involved… Slide 63 Many departments will be involved so involve them early. ©2008 GS1 The Business Case The Business Case Slide 65 ©2008 GS1 The Business Case – Common Benefits Financial Efficiencie s Customer Service Customer Satisfaction Slide 66 Environment ©2008 GS1 The Business Case – Financial Benefits Lower costs Less inventory Less work Supply chain velocity Slide 67 ©2008 GS1 The Business Case – Efficiency Benefits Better visibility Standard terms Common understanding between trading partners Lower shipping errors Slide 68 ©2008 GS1 The Business Case – Customer Service Slide 69 Time to market Customer Response Time Returns processing ©2008 GS1 Business Case – Customer Satisfaction Information Warranty provision Better service Anti-Counterfeiting Slide 70 ©2008 GS1 The Business Case – The Environment Better Disposal Lower recycling costs Tracking of hazardous material Slide 71 ©2008 GS1 The Business Case – Time Time is Money Slide 72 ©2008 GS1 The Business Case - Summary Slide 73 ©2008 GS1 Deployment Objectives Deployment Objectives Set clear and specific objectives Slide 75 ©2008 GS1 Sample Deployment Objectives Processes Slide 76 ©2008 GS1 Situation Analysis Situation Analysis A key factor to successful RFID deployment is understanding what exists before the change Slide 78 ©2008 GS1 Situation Analysis – Key Factors What are the current processes ? Where and how are they carried out ? Who executes them ? Where are items identified in the processes ? Why is identification necessary for those processes ? What materials move into and out of the processes ? What information is key about each Slide item ? 79 ©2008 GS1 Situation Analysis – Common Tools Process Maps System Maps RACI Chart Slide 80 ©2008 GS1 Situation Analysis – Radio Assessment Radio energy can be impacted by many things, so, assess your environment in this respect Slide 81 ©2008 GS1 Situation Analysis – Radio Assessment Slide 82 ©2008 GS1 Situation Analysis – Radio Assessment Host Slide 83 Reader module Antenna Tag ©2008 GS1 Building the Team Building The Team - Principles • Team-leader • Key stakeholders • Business knowledge within team • Open attitude towards change Slide 85 ©2008 GS1 Building The Team – Executive Sponsor Executive Sponsor: • Sets the goals and direction for the program • Enables you to get the resources and commitment • Senior executive within the company • Leads a function or division if possible Slide 86 ©2008 GS1 Building The Team – The Core Team The Core Team: • Stakeholders (right from start of program) • Guides program according to agreed goals and objectives • Acts as a link into the rest of the company Slide 87 ©2008 GS1 Building The Team – Motivation Motivate beyond the initial enthusiasm Hold regular training sessions, team feedback reviews, team outings etc. Be frank about what is working and what isn’t Seek the team’s ideas on how to make progress. Reward exceptional individual contributions Reward achievement of major milestones by the whole team Slide 88 THANK YOU! ©2008 GS1 Requirements Gathering Requirements Gathering - KPI’s Measurable Objective = Increase Average Revenue per Customer from 10 to 15 US Dollar by End Of Year 2008 KPI = Average Revenue per Customer Slide 90 ©2008 GS1 Planning Planning “No battle plan survives contact with the enemy” Count Helmut von Moltke the Elder 1800 – 1891 Slide 92 ©2008 GS1 Planning – Why Do It At All ? purpose and direction… what is expected and when…. checklist… communicate progress or issues… dependencies... what to do if things go wrong… Slide 93 ©2008 GS1 Planning – Level Of Detail • Not too much detail… • For simple projects written list of activities is ok • Larger projects require activities list, usually spreadsheet • Large complex projects involving multiple teams, skills and functions over a longer period of time best planned using integrated project planning tool Not planning at all is planning to fail ! Slide 94 ©2008 GS1 Process Integration Process Integration - The Basics Integrate new processes carefully in order to minimize disruption and risks Slide 96 ©2008 GS1 Process Integration - How Slide 97 Document and understand the existing and new processes so as to minimize risks and misunderstandings ©2008 GS1 The Pilot The Pilot - Why Do It At All ? Slide 99 ©2008 GS1 The Pilot - How - Start Small Slide 100 Small is beautiful – until you know it works ! ©2008 GS1 The Pilot - How - Start Small Select initially a few products … … and / or a few locations then expand if these trials are successful Slide 101 ©2008 GS1 The Pilot - How - Predict & Compare During the pilot: Monitor and record what actually happens For each part of the pilot: Describe the new processes and what to expect Slide 102 ©2008 GS1 The Pilot - How - RFID RFID equipment usually requires adjustment – this is normal ! You can ensure interoperability of tags and equipment by ensuring that they are certified Slide 103 ©2008 GS1 The Pilot - Completion Show the Executive Sponsor and the Core Team the pilot’s results and get agreement to deploy. Slide 104 ©2008 GS1 Deployment Deployment - Providing Support Slide 106 Full deployment = full risk ! ©2008 GS1 Deployment - Providing Support You should ensure adequate level of support, either remotely or locally Slide 107 ©2008 GS1 Measuring Success Measuring Success Project success comes in many forms Slide 109 ©2008 GS1 Rewarding Success Slide 110 Don’t forget to reward success ©2008 GS1 Regulatory Considerations Regulatory Considerations Ask your solution provider to ensure that your equipment is operating within the regulations for your Slide 112 country ©2008 GS1 Chapter 5 Examples of applications Introduction Some applications of EPC/RFID • • • • • • • • Asset Management (Nortura) Track and Trace in the Book industry (Byblos) Outbound / Inbound in the textile industry (Lemmi) RFID in healthcare (Hospital Speising) Cold Chain (Nestlé) Baggage tracking (Hong Kong Airport) Visibility in complex retail chain – (Wal*Mart) Optimising manufacturing processes (Griva S.p.A) Recommended exercise Slide 114 ©2008 GS1 Asset Management: Nortura • Norwegian company • Meat manufacturer • Employs 6.800 people • Annual sales €2 billion • Organized as a cooperative owned by approximately 30,300 farmers • 41 municipalities in 18 counties Problem: Today nobody knows where, which and how many Returnable Transport Items (RTI) are spead along the supply chain Source: Nortura Slide 115 ©2008 GS1 Asset Management: Nortura • Benefits • Automatical RTI lifecycle control • Documentation of RTI lifecycle (cold, freezing cold, washing, etc) • Real time inventory • Prediction of RTI need • Process management project • RFID tag inside 80000 crates with GRAI • 73 RFID readers • Employee ID coupled with GS1 GRAI • Each person gets performance feedback • ROI: 3 months Slide 116 Source: Nortura ©2008 GS1 Track & Trace in the book industry Byblos • Portuguese company • Bookstore • 50,000-square-foot store • Receiving more than 200,000 products per week Problem: Problems for localising products resulting in high costs of inventory and poor customer service Source: Byblos Slide 117 ©2008 GS1 Track & Trace in the book industry Byblos • Solution • 250,000 books, games and videos tagged • 40 RFID-enabled kiosks • 13 incorporates RFID security gates • 14 RFID point-of-sale (POS) reading stations • 10 RFID Handhelds Source: Byblos Slide 118 ©2008 GS1 Track & Trace in the book industry Byblos • Benefit • 30% less stock • Possibility to handle more customer at POS • Faster localisation of items • Faster reposition and reordering of sold items • Possibility of daily and full inventory Source: Byblos Slide 119 ©2008 GS1 Outbound / Inbound in the textile industry - Lemmi • German SME company • A leading children’s wear manufacturer • Founded in 1959 • Employs around 50 people • Produces over 1 million garments per year Problem: Poor stock turn over Source: Lemmi Slide 120 ©2008 GS1 Outbound / Inbound in the textile industry - Lemmi • Solution • 100 % of merchandise is tagged • Integrated Solution: RFID fully integrated into ERP • Benefits • Increase efficiency on all steps of SC • Increase quality of deliveries from production to customers • Precise information on goods in transit • Strengthen relationships with customers • Easy to use for all employees Source: Lemmi Slide 121 ©2008 GS1 Outbound / Inbound in the textile industry - Lemmi • Payback • Stock turnover before tagging: 5,000 to 10,000 items per day • Stock turnover after tagging: 20,000 items per day • Increase of 250%-300% in receipt and shipment of goods Source: Lemmi Slide 122 ©2008 GS1 RFID in healthcare - Hospital Speising • Austrian company • Orthopädisches Spital Speising is part of Vinzenz groupe • Total number of beds: 2221 • Hospital patients per year: 112359 • Workers in the hospitals: 4535 Introduction of RFID in instrument cycle of a hospital Slide 123 ©2008 GS1 RFID in healthcare - Hospital Speising Benefits • Detection of specific medical equipment and inventory within the hospital • Better process transparency • Automated documentation • Simplification of logistics operations • Automation of ordering • Quality improvement in the process chain • Risk reduction in the area of application • Reduce storage costs • Increase the cost-efficiency • Patient safety Slide 124 ©2008 GS1 Cold Chain - Nestlé • World's largest food company: • 2007 sales – $98 billion • 130 operating Markets • 450+ factories in 87 countries • 250,000 employees • 130+ main brands Slide 125 ©2008 GS1 Ice Cream does not like heat shocks Objectives of the trail 2007 Evaluate technical feasibility of a temperature monitoring solution along the entire cold chain Evaluate the real advantages compared to actual situation, for all organization areas involved. During kick-off meeting in June discovered other interesting issues.... Assess solution for several business needs: - Freezer traceability - Better support on freezer maintenance issues - Service to big customers (e.g. theme parks): efficient & automatic HACCP freezer performance warranty for a better support on sales activities - Systems integration requirements Installed Sensors - Distribution Delivery Truck In Freezer View Simple No to install – 5 minutes maintenance Secondary Distribution Problem with temp probe and compressor on the truck External temperature 30° External -18°C in Cold Store -10°C delivery First delivery at -23°C Last delivery at -10°C !!! Cold store temperature Truck temperature Example: Store Freezer Activity Continuous defrosting....... Ice cream quality will be a problem -12°C constant Too warm Freezer well regulated at - 22°C Too cold Different from day & night? Key Benefits Production (cold store) Primary transport Depot / Distributors Deliveries Freezer performance & management Temperature cycles – warning signs Improved quality control of products Primary DC Improved visibility of the cold-chain: Better understanding of: Primary transport Quality & Safety Improved product taste / experience Lower 'bad goods' & insurance write offs Potential energy savings Added value services to Distributor Restaurant, Bar, POS Consumer Some results and conclusions At the beginning we talked about benefits in terms of: Legal duty ensure quality in the food chain Quality of product and brand image on market Cost of bad goods Insurance costs Today we also talk about: Better management of installed freezeer : traceability, sobstitution, maintenance, allocation, energy consumption Marketing & sales support: service to customers (HACCP due activity, freezer performance, maintenance guide) allocation and match model/version freezer-location-invoicing Support for research & development: thermal history of singles batches, development of product Better efficiency on quality control: coverage, efficiency & “best practice” Significant opportunities for added value Baggage tracking – Hong Kong Airport • One of the busiest airport in the world • Passenger: 350 million per annum • Air cargo: 3 million tons per annum • Named the world’s best airport by Sky Trax (UK) in Apr 2004 & received special recognition award from IATA • ~ 40% of luggage handled comes from transfer flights • Major hub to/ from mainland & volume is expected to be increasing 134 134 ©2008 GS1 Baggage tracking – Hong Kong Airport Issues • Currency bar code system is 85-95% read rate (Manually handling failures) • Remove & check all Unit Loading Device on the plane to identify baggage • Security measurement • Velocity and Baggage handling accuracy Solutions • Deploy RFID technology on extensive baggage-handling facilities alongside the bar code system to bring up visibility, improve accuracy and efficiency, step up security measurement 135 135 ©2008 GS1 Baggage tracking – Hong Kong Airport Benefits • Improve customer satisfaction • Improve security • Cut operating costs 136 136 ©2008 GS1 Visibility in complex retail chain - Wal*Mart • Walmart operates retail stores worldwide in various format • Products allocated through 90 DCs and/or direct from manufacturer • Total sales 2004 – US$ 256.3B • Requested EPC RFID tagging by Jan 2005 to increase supply chain visibility and eliminate many manual process. • Estimated annual saving is ~ 3.3% of sales (i.e. ~ US$ 8B) 137 137 ©2008 GS1 Visibility in complex retail chain - Wal*Mart Issues • Without merchandise visibility along this huge supply chain may lead to Out Of Stocks, shrinkage, and operation inefficiency that could ultimately reduce competitive advantages Solutions • Mandated suppliers to affix EPC compliance RFID tags to cases and pallets before shipping to Walmart’s DCs. The tags allow Wal-mart utilize automatic tracking on product movement that will provide product visibility without additional human intervention. 138 138 ©2008 GS1 Visibility in complex retail chain Wal*Mart Benefits • Eliminated many manual processes in the area of I) receiving, ii) product movement in warehouse and DC, iii) shipping to stores, and iv) paying suppliers. • 139 139 Reduce inventory shrinkage and out-of-stock situations. ©2008 GS1 Visibility in complex retail chain Wal*Mart Benefits 140 140 Function Execution Scanning Eliminate bar code scanning on pallets and cases in the supply chain and on items in-store can reduce labour costs by 15% Out-of-Stock Smart shelves monitor on-shelf product availability Shrink Real-time product monitoring reduces warehouse shrink, administration errors and vendor fraud Tracking Improved tracking of the more than 1 billion pallets and cases moving through DCs annually Product Visibility Improved visibility of where products are in the supply chain in Walmert's DCs and supply's warehouses offers reduced inventory and costs of carrying this inventory ©2008 GS1 Optimising manufacturing processes – Griva S.p.A • Italian company • Founded 1955 • A leading high-volume textile manufacturer • Employs 70 people • Annual sales €14 million • Markets – 60% domestic, 40% foreign • 300,000 rolls of fabric per year • Reliance on automated manufacturing systems with integrated logistics • “An improvement in productivity was critical to our ongoing competitiveness. Until recently, we could not accurately control the contents of the roll” Gualtiero Casalegno – President, CEO and owner 141 141 ©2008 GS1 Optimising manufacturing processes – Griva S.p.A • Fabric is woven and then rolled onto cardboard tubes • Alien Gen 2 EPC compliant readers and tags • EPCglobal numbering system • Compliant with European (ETSI) regulations • Strategic read points from production to warehouse • Harsh manufacturing environment • High temperatures • Water and high humidity • Harsh chemical agents for dying • Griva needed a robust system with complete fabric roll traceability without being intrusive to the production process” Claudio Bertolo – Marketing Manager, Simet 142 142 ©2008 GS1 Optimising manufacturing processes – Griva S.p.A • Visibility • Tracking of textile rolls through production • 15 separate dying and coating stations • Improved accuracy in production treatments • Accurate information to customers • Fabric can be sorted automatically • Readers at checkpoints supports decision making by systems and operators • Cost effectiveness • Reduced manual effort in: • determining most cost effective transportation options • Building customized shipping boxes • Identification of products 143 143 ©2008 GS1 Optimising manufacturing processes – Griva S.p.A • Production velocity • Before – 400 rolls per day (2 x 10hour shifts) • After – 600 rolls per day (2 x 8 hour shifts) • From 20 rolls/hour to 37.5 rolls/hour…….+87.5% • ROI • 30% after 9 months 144 144 ©2008 GS1 Recommended exercise GROUPS (4 to 8 persons) 20-30 Minutes Benefits of EPC / RFID Major Challenges of EPC / RFID implementation Proposed applications: • Inventory control • Outbound / Inbound • Smart Shelf • Track and Trace • Anti-counterfeiting • Supply Chain Visibility Summary 146 Chapter 6 The Consumer 147 Consumer Acceptance Responsible Use Awareness Consumer Acceptance Awareness Consumer Awareness Guidance available at www.discoverrfid.org Responsible use Basic principles on Consumer confidence can be found at: http://www.discoverrfid.org/how-it-works/your-rights/data-protection-guidance.html; Consumer Guidelines for EPC on Consumer Confidence ICC Privacy Guidelines on RFID Centre for Democracy and Technology Addressing Consumer Benefits http://rfidabc.de/ http://www.discoverRFID.org http://www.fashiongrouprfid.com Consumer Benefits – Patient Safety Patient Safety - Stay Healthy New born identified with RFID bracelets preventing mix up Blood products are tracked and match with the patient Id Consumer Benefits – Food Safety Food Safety – Eat well RFID helps monitoring of freshness and quality of products RFID enables controls of authenticity and origin Consumer Benefits – Quality of Life Quality of Life – Get what you want RFID improves the postal service and speeds up the delivery RFID enhances the shopping experience Consumer Benefits – Quality of Life Quality of Life – Feel safe RFID helps you protecting your valuables from theft RFID helps ensure your airplane is properly maintained and does not contain counterfeit spare parts. Consumer Benefits – Quality of Life Quality of Life – Work better RFID protects workers in, contact with Dangerous Environments RFID saves us time at toll booths Consumer Benefits – Environment protection Environment protection – Protecting Nature RFID protects endangered species RFID allows for better and easier recycling Practical Recommendations Data Protection Overview Why is data protection law important? General Data Protection Directive General Data Protection Directive Some important obligations Data Controller MUST: • Ensure accurate data is collected and only what is strictly necessary • Ensure the data is processed for legitimate purposes • Protect the integrity of the data from unauthorised access • Notify to the data protection authority Some important obligations Data Controller MUST: • Obtain the consent from the person • Or show the processing of the personal data is needed to perform the contract • Or show the data is needed to protect the vital interests of the person E-Privacy Directive http://ec.europa.eu/justice_home/fsj/privacy/law/index_en.htm Data Protection questions on RFID Summary 167