16c Masonry Wall Design ASD Example

advertisement

ASD Wall Design for a Single Story Masonry Building W. Mark McGinley Ph.D, PE Date July , 2015 PCA Work shop Look at a Single Wythe single story CMU Building Example Slide 2 Single Story Building - Ex1 Plan of Typical Big Box - single story Flexible diaphragm reinforced 8” CMU, Load bearing and non loadbearing walls. Flex Diaphragm- High Seismic Item Roof Live Load Roof Dead Load (including joist weight) 8” CMU wall weight (grouted at 2’ OC) 8” CMU wall weight (fully grouted) Weight of Glass doors and store front 4” brick wall weight Door dead load Wind Zone Wind Exposure Soil Site Class Seismic S1 Seismic Ss Value 20 psf 20 psf 60 psf 80 psf 10 psf 40 psf 5 psf 150 mph, Risk Category II C D 0.47 1.50 3 Single Story Building Ex1 Elevations South Wall Elevation North Wall Elevation West Wall Elevation 4 East Wall Elevation Ex1 Loads Roof Load: ΡDL = 11,900 lb ΡLL = 11,500 lb Ρuplift = 31,700 lb 5 Ex1 Loads Using loads determine Critical P, M and V at support and at mid-height of walls for all load cases 6 Capacity of Wall – Single Wythe Reinforced CMU’s 7 TMS 402 Design Provisions Two Rational Design Methods Allowable Stress Design (ASD) – stresses under service level loads must be less than allowable values. Strength Design (SD) – Capacities must be greater than load effects under strength level loads (ultimate levels). Both methods can be applied to unreinforced or reinforced masonry. Today Address Reinforced ASD. Slide 8 ASD Load Combinations – IBC 2012 /ASCE 7-10 D +F D + H+ F+L D + H +F+(Lr or S or R) D +H+F+0.75(L) + 0.75(Lr or S or R) D +H+F+(0.6W or 0.7E) D +H+F+0.75(0.6W) + 0.75L+0.75(Lr or S or R) D +H+F+0.75(0.7E) + 0.75L+0.75(S) 0.6D +0.6W + H 0.6(D+F) +H + 0.7E No increase for E or W any more with Stress Recalibration – Even with alternative load cases 9 ASD - Reinforced Masonry: TMS 402 Section 8.3 Masonry in flexural tension is cracked Reinforcing steel is needed to resist tension Linear elastic theory No minimum required steel area and As limited only on special shear walls. Wire joint reinforcement can be used as flexural reinforcement No unity interaction equation – Combined loads must used interaction diagram Slide 10 Allowable Stresses for Steel Reinforcement: TMS 402 Sec. 8.3.3.1 Tension Grade 40 or 50 Grade 60 Wire joint reinforcement 20,000 psi 32,000 psi 30,000 psi Compression Only reinforcement that is laterally tied (Section 8.3.3.3) can be used to resist compression Allowable compressive stress = tensile values above Slide 11 Allowable Axial Compressive Capacity For reinforced masonry, allowable compressive capacity is expressed in terms of force rather than stress Maximum compressive stress in masonry from axial load plus bending must not exceed 0.45f’m Axial compressive stress alone must not exceed allowable axial stress from TMS 402 Section 8.2.4.1 (unreinforced Fa). Slide 12 Allowable Axial Compressive Capacity: TMS 402 Section 8.3.4.2.1 TMS 402 Equations (8- 21) and (8 - 22) define axial force limits (ASD). Slenderness reduction coefficients are identical to those used for unreinforced masonry. Allowable capacity is sum of capacity of masonry plus compressive reinforcement 2 h h ' Pa (0.25 f m An 0.65 Ast Fs ) 1 99 for r 140r 70r Pa (0.25 f An 0.65 Ast Fs ) h ' m 2 h for 99 r Slide 13 TMS 402 Section 8.3.5 – Shear in Reinforced Masonry... In design we generally: Check if shear can be resisted entirely by masonry. If not, increase cross – section or, Add shear reinforcement. Check shear stress. If still no good, increase cross – section. Next slide shows changes from past code edition! Slide 14 Masonry shear stress: TMS 402 Section 8.3.5 Shear stress is computed as: V fv Anv (8 - 24) Allowable shear stresses Fv Fvm Fvs g (8 - 25) g 10.75 for partially grouted shear walls, 1.0 otherwise. Slide 15 Masonry Shear Stress: TMS 402 Section 8.3.5 Allowable shear stresses limits: M / Vdv ≤ 0.25 Fv 3 f m' g M / Vdv 1 Fv 2 f m' g (8 - 26) (8 - 27) Can linear interpolate between limits 2 M g Fv 5 2 3 Vd v Slide 16 Masonry Shear Walls: TMS 402 Section 8.3.5.1.3 Allowable Shear Stress Resisted by the Masonry Special Reinforced Masonry Shear Walls Fv 1 P M ' 4 1.75 f m 0.25 , (8 - 29) 4 An Vd v All other masonry Fv 1 P M ' 4 1.75 f m 0.25 , (8 - 28) 2 An Vd v M/Vdv is positive and need not exceed 1.0. Slide 17 Shear Design of Reinforced Masonry: TMS 402 Section 8.3.5 - (continued) If allowable shear stress in the masonry is exceeded then: design shear reinforcement using Equation 8-30 and add Fvs to Fvm Av Fs d v Fvs 0.5 Anv s (8 - 30) Shear reinforcement is placed parallel the direction of the applied force at a maximum spacing of d/2 or 48 in. One - third of Av is required perpendicular to the applied force at a spacing of no more than 8 ft. Slide 18 ASD Reinforced MasonrySingly Reinforced - FLEXURE fm ≤ Fb C kd jd M V fv bdx T n = Es/Em and from equil. Ms= Asfsjd (at the limit) = AsFsjd Mm = ½ bjkd2fm (at limit)= ½ bjkd2Fb fs/n ≤ Fs/n k ( n )2 2( n ) n j 1 k / 3 A s bd 19 ASD Interaction Diagrams- Flexural Compression Members To design reinforced walls under combined loading must construct interaction diagram stress is proportional to strain ; assume plane sections remain plane ; vary stress ( stress ) gradient to maximum limits and position of neutral axis and back calculate combinations of P and M that would generate this stress distribution 20 Allowable Stress Interaction Diagrams • • • • • Assume single reinforced Out-of-plane flexure Grout and masonry the same Solid grouted Steel in center CL 21 ASD Interaction Diagrams Walls Singly Reinforced allowable – stress interaction diagram Linear elastic theory – tension in masonry it is ignored- Plane sections remain plane Limit combined compression stress to Fb = 0.45 F’m P ≤ Pa d usually = t/2 - ignore compression steel since not tied. 22 beff Allowable Stress Interaction Diagrams Walls - Singly Reinforced Assume Stress gradient- Range A – All the Section in compression Get equivalent force-couple about center line Pa= 0.5(fm1+fm2)An Ma= (fm1-fm2)/2 (S) S = bd2/6 Note at limit – fm1 and fm2 ≤Fb (set fm1=Fb) Note much of this is from Masonry Course Notes By Dan Abrams Also Pa must less than Eq 8-21or 8-22 h 2 h Pa (0.25 f An 0.65 Ast Fs ) 1 for 99 r 140r ' m 70r Pa (0.25 f m' An 0.65 Ast Fs ) h 2 for h 99 r 23 Distribution of concentrated loads, running bond: TMS 402 Section 5.1.3.1 Load Load Load 1 2 h 2 h/2 1 Effective Length Effective Effective Length Length Slide 24 Distribution of concentrated loads, running bond: TMS 402 Section 5.1.3.1 Load 1 Load 1 2 Effective Length 2 Effective Length Slide 25 beff Allowable Stress Interaction Diagrams Walls - Singly Reinforced Assume Stress gradient- Range B – Not All Section in compression- but no tension in steel Get equivalent force-couple about center line Pb = Cm = 0.5(fm1)atb Mb= em x Cm em =d-at/3 = t/2-at/3 =t(1/2-a/3) Note that at = kd This is valid until steel goes into tension 26 Set fm1 = Fb at limit Allowable Stress Interaction Diagrams Walls - Singly Reinforced beff Assume Stress gradient- Range C – Section in compression- tension in steel Get equivalent force-couple about center line at fs/n em =d-at/3 = t/2-at/3 =t(1/2-a/3) Cm = 0.5(fm1)atb Pc = Cm –Ts & T= As x fs From similar triangles of the stress diagram fs/n= ([d-at]/at)fm1 Mb= em x Cm –Ts(d-t/2) note that d=t/2 usually so second term goes to zero At limit fs = Fs and fm1 = Fb one or the other governs Note that at = kd 27 Effective compression width per bar: TMS 402 Section 5.1.2 For running - bond masonry, or masonry with bond beams spaced no more than 48 in. center – to – center, the width of compression area per bar for stress calculations shall not exceed the least of: Center - to - center bar spacing Six times the wall thickness (nominal) 72 in. Slide 28 Allowable Stress Interaction Diagrams Walls - Singly Reinforced NO GOOD ABOVE P CUT OFF Axial Load P Capacity envelop letting fm1 = Fb P cut off Eq 8-21 or 8-22 Range A Range B Can get a three point interaction diagram easily Most walls have low axial loads Capacity envelop letting fs = Fs Ms Mm Range C Capacity envelop letting fm1 = Fb Moment M 29 West Wall Design for Out-ofPlane Loads • • • • • • Guess at wall unit size –Usually 8” CMU. Guess at bar size location and spacing – can use max. Moment and assume steel stress governs Create interaction diagram for wall. Plot diagram and critical P &M values – If all load effects within capacity envelope wall is OK. No P-delta , or min. As, or max. As. 30 Ex 1 Out-of-Plane Wall Design Flexural Design of the Wall Trial reinforcing steel: D - .7E produces the maximum moment. Assume d =7.63/2 = 3.81 in. P = 3580 lb/ft M = 16,400 lb-in /ft Assume j = 0.9 As = M / fsjd = 16,400 lb-in /(32,000 psi×0.9×3.81 in.) = 0.15 in.2/ft Try a No. 5 bar @ 16 in. on center. This provides As=0.232 in.2 /ft Slide 31 Ex 1 Out-of-Plane Wall Design 21 Ft Wall w/ No. 5 @ 16in (Centered) total depth, t f 'm 1,800,000.00 Fb 900.00 Reduction Factor, R Es 29,000,000.00 Allowable Axial Stress, F a Fs 32,000.00 Net Area, A n d 3.81 Allowable Axial Compr, P a k balanced 0.31 width, bef f Range B Wall Height, h Radius of Gyration, r Em tensile reinforcement, A s Range C 7.63 2,000.00 h/r 21.00 feet 2.20 in 114.5 0.37 187 psi (MSJC8.3.4.2.1 ) 2 91.50 in 17,086 lb 0.23 #5 @ 16 Centered 12.00 because compression reinforcement is not tied, it is not counted k kd fb (psi) Points controlled by steel 0.01 0.04 20 0.05 0.19 105 0.10 0.38 221 0.15 0.57 351 0.24 0.91 627 0.22 0.84 560 0.24 0.91 627 0.30 1.14 851 Points controlled by masonry 0.31 1.19 900 0.40 1.52 900 0.45 1.71 900 0.50 1.91 900 Must change C mas to trapezoid 0.55 2.10 900 when k d>t 0.60 2.29 900 Moment needs to be adjusted 0.62 2.36 900 0.65 2.48 900 0.68 2.59 900 0.70 2.67 900 0.80 3.05 900 0.90 3.43 900 Pure compression C mas (lb) 5 119 504 1,202 3,441 2,817 3,441 5,838 6,416 8,230 9,258 10,287 11,316 12,344 12,756 13,373 13,990 14,402 16,459 18,517 fs Axial Force Moment Axial Force (psi) (lb) (lb-in) w/ stress axial limit -32,000 -7,435 -1 -7,435 -32,000 -7,321 429 -7,321 -32,000 -6,936 1,841 -6,936 -32,000 -6,238 4,335 -6,238 -32,000 -3,999 12,052 -3,999 -32,000 -4,623 9,936 -4,623 -32,000 -3,999 12,052 -3,999 -32,000 -1,602 20,014 -1,602 -32,000 -1,024 21,900 -1,024 -21,750 3,173 27,182 3,173 -17,722 5,138 29,996 5,138 -14,500 6,916 32,679 6,916 -11,864 8,557 35,230 8,557 -9,667 10,097 37,651 10,097 -8,887 10,690 38,583 10,690 -7,808 11,558 39,941 11,558 -6,824 12,404 41,252 12,404 -6,214 12,957 42,100 12,957 -3,625 15,616 46,026 15,616 -1,611 18,142 49,429 17,086 45,634 0 17,086 Slide 32 Ex 1 Out-of-Plane Wall Design 21 Ft Wall w/ No. 5 @ 16in (Centered) total depth, t f 'm Em 7.63 2,000.00 Wall Height, h Radius of Gyration, r 1,800,000.00 h/r 114.5 Fb 900.00 Reduction Factor, R Es 29,000,000.00 Allowable Axial Stress, F a Fs 32,000.00 Net Area, A n d 3.81 Allowable Axial Compr, P a k balanced 0.31 tensile reinforcement, A s 0.23 #5 @ 16 Centered width, bef f 12.00 0.37 187 psi (MSJC8.3.4.2.1 ) 2 91.50 in 17,086 lb 70r Pa (0.25 f m' An 0.65 Ast Fs ) h Fs = 32,000 because compression reinforcement is not tied, it is not counted k kd fb (psi) Points controlled by steel 0.01 0.04 20 0.05 0.19 105 0.10 0.38 221 0.15 0.57 351 0.24 0.91 627 0.22 0.84 560 0.24 0.91 627 0.30 1.14 851 Points controlled by masonry 0.31 1.19 900 b 0.40 1.52 900 0.45 1.71 900 0.50 1.91 900 Must change C mas to trapezoid 0.55 2.10 900 when k d>t 0.60 2.29 900 Moment needs to be adjusted 0.62 2.36 900 0.65 2.48 900 0.68 2.59 900 0.70 2.67 900 0.80 3.05 900 0.90 3.43 900 Pure compression fs/n [at/ ([d-at]) =f 32000/16.11 [.1(3.81/ ([3.81-.1(3.81]) 21.00 feet 2.20 in C mas (lb) 5 119 504 1,202 3,441 2,817 3,441 5,838 6,416 8,230 9,258 10,287 11,316 m 12,344 12,756 13,373 13,990 14,402 16,459 18,517 70(2.2) Pa (0.25) 2000) 21x12 2 for h 99 r 2 fs Axial Force Moment Axial Force (psi) (lb) (lb-in) w/ stress axial limit -32,000 -7,435 -1 -7,435 -32,000 -7,321 429 -7,321 -32,000 -6,936 1,841 -6,936 -32,000 -6,238 4,335 -6,238 -32,000 -3,999 12,052 -3,999 -32,000 -4,623 9,936 -4,623 -32,000 -3,999 12,052 -3,999 -32,000 -1,602 20,014 -1,602 -32,000 -1,024 21,900 -1,024 -21,750 3,173 27,182 3,173 mas -17,722 5,138 29,996 5,138 -14,500 6,916 32,679 6,916 -11,864 8,557 35,230 8,557 m s -9,667 10,097 37,651 10,097 -8,887 10,690 38,583 10,690 -7,808 11,558 39,941 11,558 -6,824 12,404 41,252 12,404 -6,214 12,957 42,100 12,957 -3,625 15,616 46,026 15,616 -1,611 18,142 49,429 17,086 45,634 0 17,086 P=221 – 0.23 x 32000 C =0.5x0.1(3.81)(12)(221) Mb= e x C –T (d-t/2) =(3.81-( 0.1 x 3.81/3)x32000x0.23 Slide 33 Ex 1 Out-of-Plane Wall Design 21 Ft Wall w/ No. 5 @ 16in (Centered) total depth, t f 'm Em 7.63 2,000.00 Wall Height, h Radius of Gyration, r 1,800,000.00 h/r 114.5 Fb 900.00 Reduction Factor, R Es 29,000,000.00 Allowable Axial Stress, F a Fs 32,000.00 Net Area, A n d 3.81 Allowable Axial Compr, P a k balanced 0.31 tensile reinforcement, A s width, bef f 21.00 feet 2.20 in 0.37 187 psi (MSJC8.3.4.2.1 ) 2 91.50 in 17,086 lb 0.23 #5 @ 16 Centered 12.00 because compression reinforcement is not tied, it is not counted k kd fb (psi) Points controlled by steel 0.01 0.04 20 0.05 0.19 105 0.10 0.38 221 0.15 0.57 351 0.24 0.91 627 0.22 0.84 560 0.24 0.91 627 0.30 1.14 851 Points controlled by masonry 0.31 1.19 900 0.40 1.52 900 0.45 1.71 900 0.50 1.91 900 Must change C mas to trapezoid 0.55 2.10 900 when k d>t 0.60 2.29 900 b Moment needs to be adjusted 0.62 2.36 900 0.65 2.48 900 0.68 2.59 900 0.70 2.67 900 b900 0.80 3.05 0.90 3.43 900 Pure compression fb=Fb = 900 C mas (lb) 5 119 504 1,202 3,441 2,817 3,441 5,838 6,416 8,230 9,258 10,287 11,316 12,344 12,756 13,373 13,990 14,402 m 16,459 18,517 fs Axial Force Moment Axial Force (psi) (lb) (lb-in) w/ stress axial limit -32,000 -7,435 -1 -7,435 -32,000 -7,321 429 -7,321 -32,000 -6,936 1,841 -6,936 -32,000 -6,238 4,335 -6,238 -32,000 -3,999 12,052 -3,999 -32,000 -4,623 9,936 -4,623 -32,000 -3,999 12,052 -3,999 -32,000 -1,602 20,014 -1,602 -32,000 -1,024 21,900 -1,024 -21,750 3,173 27,182 3,173 -17,722 5,138 29,996 5,138 -14,500 6,916 32,679 6,916 -11,864 8,557 35,230 8,557 -9,667 10,097 37,651 10,097 mas 38,583 -8,887 10,690 10,690 -7,808 11,558 39,941 11,558 -6,824 12,404 41,252 12,404 -6,214 12,957 42,100 12,957 m -3,625 s 15,616 46,026 15,616 -1,611 18,142 49,429 17,086 45,634 0 17,086 P=221 – 0.23 x 32000 fs = [d-at/ ([at]) nf C =0.5x0.4(3.81)(12)(900) 16.11 [(3.81 -0.4(3.81/ (0.4(3.81])(900 x 16.11 M = e x C –T (d-t/2) =(3.81-( 0.1 x 3.81/3)x32000x0.23 Slide 34 Ex 1 Out-of-Plane Wall Design 21 Ft Wall w/ No. 5 @ 16in (Centered) total depth, t f 'm 7.63 2,000.00 Wall Height, h Radius of Gyration, r Em 1,800,000.00 Fb 900.00 Reduction Factor, R Es 29,000,000.00 Allowable Axial Stress, F a Fs 32,000.00 Net Area, A n d 3.81 Allowable Axial Compr, P a k balanced 0.31 tensile reinforcement, A s width, bef f h/r 21.00 feet 2.20 in 114.5 0.37 187 psi (MSJC8.3.4.2.1 ) 2 91.50 in 17,086 lb 0.23 #5 @ 16 Centered 12.00 because compression reinforcement is not tied, it is not counted k kd fb (psi) Points controlled by steel 0.01 0.04 20 0.05 0.19 105 0.10 0.38 221 0.15 0.57 351 0.24 0.91 627 0.22 0.84 560 0.24 0.91 627 0.30 1.14 851 Points controlled by masonry 0.31 1.19 900 0.40 1.52 900 0.45 1.71 900 0.50 1.91 900 Must change C mas to trapezoid 0.55 2.10 900 when k d>t 0.60 2.29 900 Moment needs to be adjusted 0.62 2.36 900 0.65 2.48 900 0.68 2.59 900 0.70 2.67 900 0.80 3.05 900 0.90 3.43 900 Pure compression C mas (lb) 5 119 504 1,202 3,441 2,817 3,441 5,838 6,416 8,230 9,258 10,287 11,316 12,344 12,756 13,373 13,990 14,402 16,459 18,517 fs Axial Force Moment Axial Force (psi) (lb) (lb-in) w/ stress axial limit -32,000 -7,435 -1 -7,435 -32,000 -7,321 429 -7,321 -32,000 -6,936 1,841 -6,936 -32,000 -6,238 4,335 -6,238 -32,000 -3,999 12,052 -3,999 -32,000 -4,623 9,936 -4,623 -32,000 -3,999 12,052 -3,999 -32,000 -1,602 20,014 -1,602 -32,000 -1,024 21,900 -1,024 -21,750 3,173 27,182 3,173 -17,722 5,138 29,996 5,138 -14,500 6,916 32,679 6,916 -11,864 8,557 35,230 8,557 -9,667 10,097 37,651 10,097 -8,887 10,690 38,583 10,690 -7,808 11,558 39,941 11,558 -6,824 12,404 41,252 12,404 -6,214 12,957 42,100 12,957 -3,625 15,616 46,026 15,616 -1,611 18,142 49,429 17,086 45,634 0 17,086 Slide 35 Ex 1 Out-of-Plane Wall Design ASD Interaction Diagram 8 in Wall, 21 ft high, #5 @ 16 in. Centered 20,000 P , lb per foot of length 15,000 10,000 5,000 0 0 10,000 20,000 30,000 40,000 50,000 60,000 Capacity D + Lr D + .6W: D-.7E D + 0.75 (.6)W + 0.75 Lr D - 0.75 (0.7E) 0.6 D + .6W: 0.6 D +0.7 E: -5,000 -10,000 M, lb-in per foot of length Slide 36 Example Shear wall in a single story Building Shear Wall Ex2 7 North Wall 8 VD1N2 2 1 East 2 Wall 2 West wall North Wall 1 East Wall 2 Diaphragm 1 North Wall A 1 Plan of Typical Big Box - single story Flexible diaphragm VD1N1 VD1E2 VD1E1 East Wall 1 East Wall 1 West Wall West Wall Diaphragm 2 Diaphragm2 See MDG for Load determination and distribution to shear wall lines - Flex Diaphragm – SDCD E VD2S South Wall 37 VD2W VD2E1 VD2N1 Look at Shear Wall Design To check wall segments under in -plane loads must first • • Distribute Load to Shear wall lines – Either by Trib. Width or Rigid Diaphragm analysis. Distribute Line load to each segment w.r.t. relative rigidity. 38 Shear Wall Loads Distribution Segments get load w.r.t. relative k East Wall 2 1 2 8 5 6 7 4 160.8 kips Diaphragm Shear due to seismic 1 2 3 West Wall Elevation 1 2 3 4 5 7 6 8 9 East Wall Elevation 1 2 3 4 5 7 6 8 9 10 South Wall Elevation North Wall 2 10 9 8 7 6 5 4 3 2 North Wall Elevation 39 1 Shear Wall Loads Distribution Segments get load w.r.t relative k • For Cantilevered Shear wall segments • h' h ' k c Em t 4 3 lw lw For Fixed-Fixed Shear wall segments 1 3 h' h' kc Emt 3 lw lw 3 1 40 Shear Wall Load Distribution Table18.1-2 DPC Box Building Shear Load on Wall Segments on the West Wall DPC Box West Wall (Grid 1) Segment h l 1 22 12 2 22 24 3 22 24 4 22 24 5 22 24 6 22 24 7 22 24 8 22 6.67 Sum Ri 0.332 1.715 1.715 1.715 1.715 1.715 1.715 0.065 10.687 Vd = 160.8 kips Vi from Diaphragm (lb) Vi wt (lb) 4.99 4.05 25.80 8.1 25.80 8.1 25.80 8.1 25.80 8.1 25.80 8.1 25.80 8.1 0.98 2.25 160.800 41 Shear Wall Load Distribution Table18.1-2 DPC Box Building Shear Load on Wall Segments on the West Wall DPC Box West Wall (Grid 1) Segment h l 1 22 12 2 22 24 3 22 24 4 22 24 5 22 24 6 22 24 7 22 24 8 22 6.67 Sum 22 22 Ri 10 4 3 12 12 3 Ri 0.332 1.715 1.715 1.715 1.715 1.715 1.715 0.065 10.687 1 Vd = 160.8 kips Vi from Diaphragm (lb) Vi wt (lb) 4.99 4.05 25.80 8.1 25.80 8.1 25.80 8.1 25.80 8.1 25.80 8.1 25.80 8.1 0.98 2.25 160.800 1.715 Vi 160.8 10.687 42 Segment 2 Designed in later Example Design of Reinforced Masonry (ASD) In Plane Loading (shear Walls) Axial Force V h L 43 ASD Design of Reinforced Masonry -In Plane Loading (Shear Walls) Still use interaction diagrams Axial Load is still dealt with as out of plane (M=0) In plane load produces moment and thus moment capacity is dealt with slightly differently 44 P-M Diagrams ASD-In Plane Initially assume fm = Fb and Neutral Axis then same as out-of-plane but area and S are based on Length = d and t = b use OOP equations in Range A and B. Adjust aL as before until rebars start to go into tension. Note that aL = kd Determine fsi from similar triangles & get Ti Check extreme fsi ≤ Fs & fm ≤ Fb Cm = aL x b x ½ Fb (or fm when fsn = Fs) M capacity (Σabout center)= Σ (Ti x (di -L/2) + Cm 45 x(L/2 – aL/3)) Reinforced Masonry Shear Walls - ASD Axial Force ~ 0 V h L V= base shear P M = overturning moment 46 Reinforced Masonry Shear Walls - ASD V Flexure Only P = 0 on diagram Multiple rebar locations h L M = over turning moment V= base shear P- self weight only ignore 47 Reinforced Masonry Shear Walls – ASD (P =0) Can use the singly reinforced equations di – location to centroid of each bar Tension fsn/N<= Fs/N Compression d*– location centroid of all bars in tension f*si/N k*d* fsi/N fsi/N fsi/N fsi/N fsi/N fsi/N fsi/N Fs1/N fsi/N Fsc/N Tsn= Fs As Ti Ti Ti Ti Ti L Ti Ti Ti T1 fm Cm V= base shear M = over turning moment 48 Moment only ASD In Plane To locate Neutral Axis – Guess how many bars on tension side – As* Find d* (centroid of tension bars) and *=As*/bd* Get k* = ((*n)2 + 2*n)1/2 – n* Unless tied ignore compression in steel. 49 Moment only ASD In Plane Check k* d* to ensure assume tension bars correct – iterate if not Determine fsi from similar triangles and Ti M capacity (Σabout C)= Σ (Ti x (di – k*d*/3)) 50 Shear Wall Example 3 Geometry: typical wall element: 25 ft – 4 in. total height 3 ft – 4 in. parapet 24 ft length between control joints 8 in. CMU grouted solid: 80 psf dead VD 25’-4” VP 22’-0” 12’-8” f’m = 1500 psi 24’-0” 51 Shear Wall Example 3 West Wall seismic load condition Vdiaphragm= 25,800 lb acting 22 ft above foundation Vpier = 8,100lb acting 12.7 ft above foundation 8 in. CMU grouted solid (maximum possible dead load) Pbase = 80lb/ft2 x 25.3 ft x 24 ft = 48,6 00 lb Vertical Seismic: Vpier = 0.2 SDSD= (-0.2 (1.11)(48,600 )=10,800 lb ASD Load Combination 0.6 D + 0.7 E P = 0.6 x 48,600 + 0.7 x-0.2 (1.11) (48,600 ) = 21,600lb M = 0.6 x 0 + 0.7 x (25,800 lb x 22ft + 8,100lb x 12.7ft) = 469,000lb-ft = 5,630,000 lb in. V = 0.6 x 0 + 0.7 x (25,800 lb + 8,100 lb) = 23,700 lb 52 Shear Wall Example 3 #5 bar (typ) 4” 8” 8” 24” 24” Assume the rebar in the wall are as shown – Axial load is negligible – ignore - To simplify assume that only three end bars are effective (only lap these to foundation) 53 Shear Wall Example 3 For the 24 ft long wall panel between control joints subjected to in-plane loading, the flexural depth is the wall length less the distance to the centroid of the vertical steel at the ends of the wall. d 12 in (24 ft 12 in / ft ) 12 in 276 in We are using 3 #5 Bars but if needed an estimate of As can be Assumedetermined that j = 0.9 The area jof=reinforcing steel canmoment be calculated by required assuming .9 and applied , Mas: 5,630,000 lb in M M 5 , 630 , 000 lb 2 in M As Fs jd As req 'd 0.944 in 2 2 Fs jd 24,000 lb in 0.9 276 Asreq in 0.71in Fs jd 32,000 psi 0.9 276in Es 29000000 n 21.48 21.5 Em 900(1500) 54 Shear Wall Example 3 Try 3 No. 5 bars, As = 3 × 0.31 in.2 = 0.93 in.2 Calculate j and k: As 0.93 in 2 0.000442 bd 7.63 in 276 in n 21.5 0.000442 0.00950 k 2n n n 2 0.00950 (0.00950) 2 0.00950 0.129 2 k 0.129 j 1 1 0.957 3 3 You need to get the stress at the centroid based on the extreme bar fs=Fs 276-kd x 32,000 31,476 psi Should get third bar stress then S Moments but M ≈ 280 kd M 0.93 in 2 31,476 lb in 2 0.957 276 in 7,732,000 lb in 5,630,000 lb in ok Check Masonry Compression Stresses Fb 0.45 f' m 0.45 1500 psi 675 psi fb M 5,630,000 157 psi 0675 psi 2 2 0.5 jkbd 0.5(0.957)0.129(7.63)(276) 55 Shear Wall Example 3 Check Shear Stress Assume no shear reinforcing and thus Fv Fvm Fvs Fvm P M ' 1 Fvm 4 1 . 75 f 0 . 25 m 2 An Vd 5,630,000 0 1 4 1.75 1500 0.25 2 An 23,700 ( 276 ) 48.3 psi Fv (Conservatively) 2 f m' 2 1500 77.5 psi OK 56 Shear Wall Example 3 Check Shear Stress Conservatively assume just face shell bedded areas resist shear V 23,700lb fv 33.9 psi 48.3 psi OK Anv 280(1.25)2 57 Shear Wall Design So the Final Design – can use the # 5 at the ends of the wall – ignoring any bars that will likely be there for out-of-plane loading #5 bar (typ) 4” 8” 8” 24” 24” Check Prescriptive Seismic Reinforcing 58 Requirements for Detailed Plain SWs and SDC C: TMS 402 Section 7.3.2.3 roof connectors @ 48 in. max oc roof diaphragm #4 bar (min) within 16 in. of top of parapet Top of Parapet #4 bars around openings #4 bar (min) within 8 in. of corners & ends of walls 24 in. or 40 db past opening #4 bar (min) @ diaphragms continuous through control joint #4 bar (min) within 8 in. of all control joints control joint #4 bars @ 10 ft oc #4 bars @ 10 ft oc or W1.7 joint reinforcement @ 16 in. oc Slide 59 Seismic Design: TMS 402 Chapter 7 Seismic Design Category D Masonry that is part of the lateral force – resisting system must be reinforced so that v + h 0.002, and v and h 0.0007 Type N mortar and masonry cement mortars are prohibited in the seismic force – resisting system Shear walls must meet minimum prescriptive requirements for reinforcement and connections (special reinforced) Other walls must meet minimum prescriptive requirements for horizontal and vertical reinforcement Slide 60 Requirements for Special Reinforced Shear Walls: TMS 402 Section 7.3.2.6 roof connectors @ 48 in. max oc roof diaphragm #4 bar (min) within 16 in. of top of parapet Top of Parapet #4 bars around 24 in. or 40 db openings past opening #4 bar (min) within 8 in. of corners & ends of walls #4 bar (min) @ diaphragms continuous through control joint #4 bar (min) within 8 in. of all control joints control joint #4 bars @ 4 ft oc #4 bars @ 4 ft oc Slide 61 Seismic Design Categories E and F: TMS 402 Section 7.4.5 Additional reinforcement requirements for masonry not laid in running bond and used in nonparticipating elements Horizontal Reinforcement of at least 0.0015 Ag Horizontal Reinforcement must be no more than 24 in. oc. Must be fully grouted and constructed of hollow open-end units or two wythes of solid units Slide 62

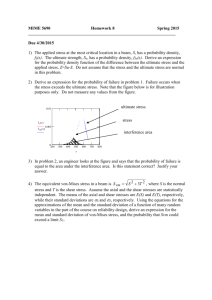

![Applied Strength of Materials [Opens in New Window]](http://s3.studylib.net/store/data/009007576_1-1087675879e3bc9d4b7f82c1627d321d-300x300.png)