21 Cladding With Metal and Glass

Aluminum Extrusions

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum Extrusions

Alumnium in Curtain

Walls

• Aluminum is most common in

metal curtain wall because it:

–

–

–

–

Protects against corrosion

Accepts and holds a variety of

attractive surface finishes

Can be fabricated into elaborate

shapes by extrusion

Is light and strong

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum Extrusions

Extrusion Production

• The principle of extrusion is

easily visualized:

–

–

It is like squeezing

toothpaste from a tube

The tube extrudes a

column of toothpaste in

the shape of the orifice

which is cylindrical

• Very intricate aluminum

sections can be extruded for

variety of purposes including

curtain wall components,

door frames, window

frames, entrances,

storefronts, handrails,

grillwork, and structural

shapes

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum Extrusions

Extrusion Production

1.

2.

3.

4.

Hundreds of extrusion

dies for many components

of curtain walls are

organized in racks

A heated billet of

aluminum is inserted into

the cylinder of the

extrusion press

An extrusion emerges

from the die

Long extrusions cool on

rollers, ready for

straightening and cutting

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

1

2

3

4

Aluminum Extrusions

Connections of Extruded

Shapes

1.

2.

Screw ports are extruded

1

cylindrical features that

allow a screw to be driven

in parallel to the long axis

of the extrusion

Self-tapping screws are

driven through screw ports

to fasten an extruded

aluminum shear block to

a vertical mullion

2

2

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum Extrusions

Connections of Extruded

Shapes

1.

2.

Screw slots allow screws to

be driven perpendicular to

the long axis of an

extrusion

Snap-on and snap together

features are commonly

used in extruded

aluminum curtain wall

components

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

1

2

Aluminum Extrusions

Thermal Breaks and

Finishes

• Thermal breaks

–

–

They are internal components of

insulating material that thermally isolate

the aluminum on the interior side from

the exterior side

They dramatically reduce heat flow

• Creating thermal breaks

–

–

Cast and debridged thermal break

Inserting Rubber, plastic gaskets or

plastic strips

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum Extrusions

Thermal Breaks and

Finishes

• This aluminum glazing

extrusion relies on an

extruded rubber gasket

(1) to act as a conductive

separation between the

pressure cap and the

main body of the

extrusion

• Such thermally improved

glazing systems are less

expensive than fully

thermally broken systems,

but also allow greater heat

loss

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

1

Aluminum Extrusions

Thermal Breaks and

Finishes

• Surface finishes

–

–

–

–

–

–

Aluminum does not corrode but forms a

tenacious oxide film

Anodizing is a process that produces an integral

oxide coating on the aluminum. It can be done

in different colors

Organic coatings can also be used such as

fluoropolymer coatings, polyvinyl fluoride

(PVF) and are available in broad spectrum of

colors are most expensive but have high service

life

Powder coatings are manufactured with

thermosetting powders applied electrostatically.

Baked enamel finish consists of spray applied

acrylic or polyester polymers and have high

gloss

A wide range of surface effects are also possible

by mechanical and chemical means

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum and Glass Framing Systems

Thermal Breaks and

Finishes

• A clear-anodized

storefront

system

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

21 Cladding With Metal and Glass

Aluminum and Glass

Framing Systems

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Aluminum and Glass Framing Systems

3

Framing Systems

1.

Entrances

–

2.

Storefronts

–

–

–

3.

These are systems of aluminum framed

doors, hardware, aluminum framing and

glass typically used in commercial

buildings

These are based on simplified, lighter

framing elements that are less expensive

and quicker to assemble than curtain wall

Rather then being hung it is installed

between floor slabs or wall openings

They are lighter and mostly used on

single storey

Curtain wall

–

They are more high performance and

can be used on any number of stories

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

2

1

21 Cladding With Metal and Glass

Modes of Assembly

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Stick System

• Principal components are:

–

–

–

Metal mullions

Rectangular panels of glass

Rectangular panels of

spandrel

• All materials are assembled

on the building

• Low shipping bulk and high

degree of ability to adjust to

unforeseen conditions

• Assembly on site more labor

intensive and impacted by

site conditions

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Unit System

• Units with glass spandrel

and mullion are shipped to

site

• Units need more space for

shipping and more

protection from damage

then stick systems

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Unit and Mullion System

• Mullion and units are

shipped separately

• Hybrid between unit and

stick systems

• Seldom used in today’s

construction

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Panel System

• Made up of homogenous

units that are formed from

metal sheet

• Advantages and

disadvantages are similar to

unit system but its

production involves higher

tooling costs of a custom

made die or mold

• It is advantageous for

buildings that requires large

numbers of similar pieces

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Column-Cover-andSpandrel-System

• Emphasizes the structural

module of the building

rather than creating its own

grid on the facade

• A custom design must be

created for each project

• Special care required in

detailing spandrel panel

support to ensure that

panels do not deflect when

loads are applied to spandrel

beams of the building frame

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Outside Glazed Curtain

Wall System

Kawneer 1600 System – Outside Glazing

In an outside glazed system

the glass must be installed or

replaced by workers standing

on scaffolding. Outside

glazing systems utilize

relatively simple set of

shapes and are less

expensive

1.

Vertical mullions

2.

Horizontal mullions

3.

Shear block

4.

Glazing gaskets

5.

Pressure plates

6.

Snap on cover

7.

Molded rubber plug

1

3

7

5

2

6

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

4

Modes of Assembly

Outside Glazed Curtain

Wall System

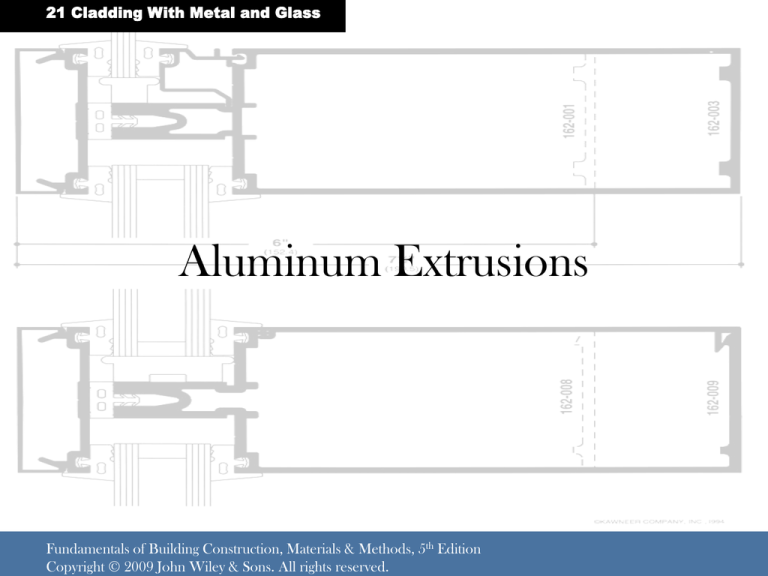

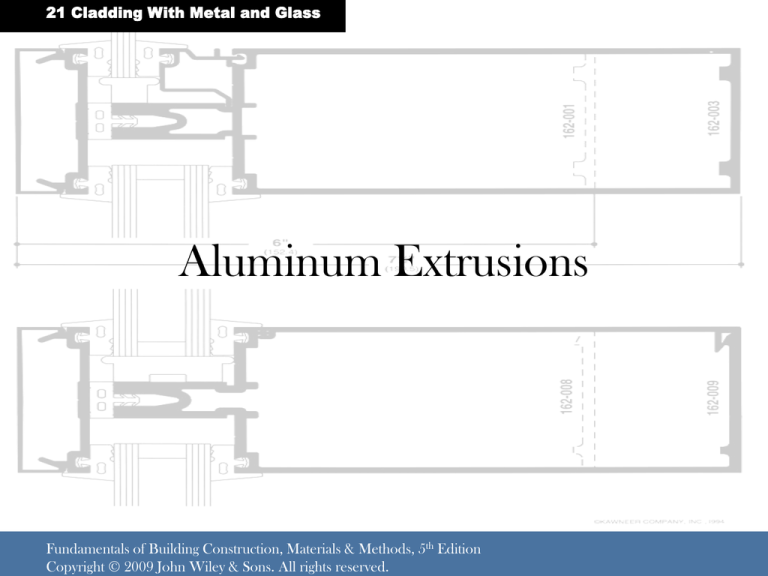

Manufacturer’s details for

Kawneer 1600 – outside

glazed system. The details

are keyed to location shown

on top left

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Outside Glazed Curtain

Wall System

1

2

Detail of a vertical mullion

1.

Basic extrusion is a rectangular shape

that provides a neat appearance on the

inside

2.

Broken lines indicate a smaller profile

availability

3.

The extruded plastic thermal break

attaches to the mullion with a projecting

pine tree spline

4.

Glazing gaskets attach to aluminum

pieces with projecting splines

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

4

4

3

4

4

Modes of Assembly

Outside Glazed Curtain

Wall System

2

1

Detail of horizontal mullion

– closed extrusion top and

open-back extrusion bottom

1.

Rubber setting blocks are shown beneath the

glass

2.

Aluminum extrusion added for spandrel glass

3.

Weep holes are not shown but drilled

horizontally through the top part of pressure plate 3

4.

Weep holes are also drilled vertically through the

bottom part of the snap on cover

1

4

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Inside Glazed Curtain

Wall System

An example of a building

with outside glazed curtain

wall system

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Inside Glazed Curtain

Wall System

5

1

In an inside glazed system

workers stand inside the

building to install the glass. It

is more convenient and

economical for tall buildings

but requires more elaborate

extrusions

1.

Vertical mullions

2.

Horizontal mullions

3.

Shear block

4.

Glazing gaskets

5.

Pressure plates

6.

Snap on cover

7.

Bottom half extrusion

3

4

6

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

2

7

Modes of Assembly

Inside Glazed Curtain

Wall System

Manufacturer’s details for

Kawneer 1600 – inside

glazed system. The details

are keyed to location shown

on top left

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Inside Glazed Curtain

Wall System

1

2

Detail of a vertical mullion

1.

Basic extrusion is a rectangular shape

that provides a neat appearance on the

inside

2.

Broken lines indicate a smaller profile

availability

3.

Thermal break is an H shaped extrusion

of rigid plastic that is crimped securely

into grooves

4.

Removable glazing gaskets

5.

Glazing pockets of different depths to

allow for glazing from the inside

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

4

5

4

3

Modes of Assembly

Inside Glazed Curtain

Wall System

Detail of horizontal mullion

1.

Bottom half of mullion is off until glass is

installed

2.

Interior glazing gaskets are installed after

the bottom part of the mullion. They are

called glazing wedges because of their

blunt wedge shape

3.

3

2

Exterior gaskets have a different shape

which are installed before the glass is

installed

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

1

Modes of Assembly

Inside Glazed Curtain

Wall System

2

4

Installing glass from

inside

1.

1

Setting blocks and

exterior side gaskets are

installed

4

2

2.

Glass unit is pushed

obliquely into the deep

glazing pocket squared

away and backed into

the shallow pocket

3.

Bottom half of mullion

is installed (see previous

slide #1)

4.

Inside gaskets are

installed

1

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Modes of Assembly

Inside Glazed Curtain

Wall System

An example of a building

with inside glazed curtain

wall system

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

2

21 Cladding

With Metal and Glass

3

1

The Rainscreen Principle in

Metal-and-Glass Cladding

1

4

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Rain Screen Principle in Metal-and-Glass Cladding

Rain Screen Principle

•

•

•

During a wind-driven rain gravity and capillary

action would be likely to draw some water

past the outer gasket

If water has leaked in along the vertical edge it

will fall by gravity to the bottom where it

drains out

If water accumulates in the horizontal mullion

it is prevented from running out at the ends

by plugs shown earlier

1.

2.

3.

4.

2

3

1

1

Its only recourse is to drain through weep

holes in the pressure plate and the snap-on

cover

External gasket serves only as a deterrent seal,

essentially a rainscreen

Internal gasket serves as an air barrier

Hollow spaces are pressure equalization

chamber

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

4

Rain Screen Principle in Metal-and-Glass Cladding

Rain Screen Principle

•

•

A sheet metal, rain screen cladding system

Behind the metal skin is metal framing for supporting

the panels, a drainage space, and a waterproof

membrane

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

21 Cladding With Metal and Glass

Expansion Joints in Metaland-Glass Walls

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Expansion Joints in Metal-and-Glass Walls

Attachment and Joints in

Mullion

1.

•

•

Vertical mullions are

attached to the edges of the

building’s floor with angle

anchor. Oval slots (4) allow

for adjustments to

accommodate construction

tolerances

Sections of vertical mullions

are spliced with aluminum

internal spline shown with

dotted lines

The spline is screwed to the

lower section of mullion with

upper section free to slide to

accommodate vertical

movement

1

4

3

2

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

21 Cladding With Metal and Glass

Sloped Glazing

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

Sloped Glazing

Sloped Glazing

Kawneer 1600 S.G. Framed With Aluminum

Extrusions Incorporating Internal Gutters

• Water leakage is a big issue

and therefore there is an

internal drainage system

• Structural issues need to be

considered and laminated or

plastic glass is often required

• Moisture condensation can

also be contained by the

gutter

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.

21 Cladding With Metal and Glass

MasterFormat Sections

For Cladding With Metal

and Glass

CSI/CSC MASTERFORMAT SECTIONS FOR CLADDING WITH METAL AND GLASS

08 40 00

ENTRANCES, STOREFRONTS, AND CURTAIN WALL

08 41 00

Entrances and Storefronts

Aluminum-Framed Entrances and Storefronts

08 44 00

Curtain Wall and Glazed Assemblies

Glazed Aluminum Curtain Walls

Sloped Glazing Assemblies

Fundamentals of Building Construction, Materials & Methods, 5th Edition

Copyright © 2009 John Wiley & Sons. All rights reserved.