Segmental Retaining Walls (Gravity)

advertisement

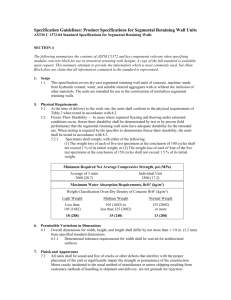

Navascape Products | MasterFormat Specifications Section 32 32 23 – Segmental Retaining Walls (Gravity) Note: This is a guide specification for gravity segmental retaining wall applications over a compacted aggregate base. The text must be edited to suit specific project requirements. This Section includes the term “Architect”. Edit this term as necessary to identify the design professional in the General Conditions of the Contract. PART 1 GENERAL 1.01 SUMMARY A. The work covered by this section includes the furnishing of all labor, materials, equipment, and incidentals for the construction and inspection of a segmental retaining wall including drainage system as shown on the Contract Drawings and Construction specifications. The work included in this section includes but is not limited to, the following: a. b. c. d. e. Furnishing and placement of leveling base. Furnishing and placement of drainage system. Furnishing and placement of geotextile. Furnishing and placement of segmental retaining wall units. Furnishing, placement and compaction of backfill drainage and retained soils. B. Related Sections a. b. c. d. e. f. 1.02 Section [ Section [ Section [ Section [ Section [ Section [ ] – Site Clearing. ] – Excavation and Fill. ] – Aggregate Base. ] – Geotextile. ] –Drainage. ] – Aggregates for Earthwork. REFERENCES Note: All retaining walls should be designed in consultation with a qualified civil engineer, in accordance with established geotechnical procedures, NCMA Design Manual For Segmental Retaining Walls, and in accordance with all jurisdictional regulations. A. American Society of Testing and Materials (ASTM): a. b. c. d. e. f. g. h. i. j. k. l. m. ASTM C 33 - Specification for Concrete Aggregates ASTM C 136 - Method for Sieve Analysis for Fine and Coarse Aggregate ASTM C 140 - Sampling and Testing Concrete Masonry Units ASTM C150 - Specification for Portland Cement ASTM C 979 - Specification for Pigments for Integrally Colored Concrete ASTM C 1372 - Standard Specification for Segmental Retaining Wall Units ASTM D G51 - Soil pH ASTM D 422 - Gradation of Soils ASTM D 424 - Atterburg Limits of Soils ASTM D 698 - Moisture Density Relationship for Soils, Standard Method ASTM D 1248 - Specification for Corrugated Plastic Pipe ASTM D 3034 - Specification for Polyvinyl Chloride (PVC) Plastic Pipe ASTM D 4751 - Standard Test Method for Apparent Opening Size B. Canadian Standards Association (CSA): a. b. c. d. e. CSA A231.2 - Precast Concrete Pavers CSA A23.2A - Sieve Analysis of Fine and Coarse Aggregates CSA A23.1 FA1 - Concrete Materials and Methods of Concrete Construction CSA A23.4 - Precast Concrete Materials and Construction CAN A3000 - Cementitious Materials Compendium Segmental Retaining Walls (Gravity) Page 1 Navascape Products | MasterFormat Specifications C. Ontario Provincial Standard Specifications (OPSS) a. OPSS 1010 - Material Specification for Aggregates – Base, Subbase, Select Subgrade, and Backfill Material b. OPSS 1352 - Material Specification for Precast Concrete Barriers 1.03 SUBMITTALS A. In accordance with Conditions of the Contract and Division 1 Submittal Procedures Section. B. Shop drawings sealed by a registered professional engineer in the [province] [state] (5 sets) submitted in accordance with Section [ ]. Shop drawings to include: a. b. c. d. e. Retaining wall profile Cross sections Site Specific details (if applicable) [corners, steps, etc] Segmental retaining wall unit dimensions and details Project notes C. Sieve analysis of granular base and backfill materials. D. Segmental retaining wall blocks: a. Samples of segmental retaining wall units to indicate color and face texture. Color will be selected by the Architect/Engineer/Landscape Architect/Owner from manufacturer’s available colors. b. Accepted samples become the standard of acceptance for work. c. Test results from an independent testing laboratory for compliance of segmental retaining wall unit requirements to [ASTM C1372] [or other applicable requirements]. d. Manufacturer’s catalogue product data, installation manual and material safety data sheets for the safe handling of the specified materials and products. 1.04 QUALITY ASSURANCE A. Retaining Wall Subcontractor Qualifications: a. Installation shall be by a contractor and crew, having successfully completed segmental retaining wall installations on projects of similar nature, complexity, or dollar cost. b. Contractor shall conform to all local, state/provincials licensing and bonding requirements. B. Regulatory Requirements and Approvals: [specify applicable licensing, bonding, etc.] 1.05 DELIVERY, STORAGE AND HANDLING A. General: Comply with Division 1 Product Requirements Section. B. Comply with all manufacturer’s ordering instructions and lead-time requirements to avoid construction delays. C. Delivery: Deliver materials in manufacturer’s original, unopened, undamaged containers packaging with identification labels intact. a. Coordinate delivery and retaining wall construction schedule to minimize interference with normal use of buildings adjacent to project. b. Deliver segmental retaining wall units to the site in steel banded, plastic banded, or plastic wrapped cubes capable of transfer by forklift or clamp lift. c. Unload units at job site in such a manner that no damage occurs to the product. D. Storage and Protection: Store materials protected such that they are kept free from mud, dirt and other foreign materials. Segmental Retaining Walls (Gravity) Page 2 Navascape Products | MasterFormat Specifications E. Coordinate delivery and building schedule to minimize interference with normal use of buildings adjacent to construction. 1.06 ENVIRONMENTAL CONDITIONS A. Do not install base or backfill material during heavy rain or snowfall. B. Do not install base backfill or segmental retaining wall units over frozen or saturated base or sub-base materials. C. Do not install frozen or saturated base or backfill materials. D. Do not install segmental retaining wall units on improperly prepared base material. PART 2 PRODUCTS 2.01 SEGMENTAL RETAINING WALL UNITS A. Manufacturer: a. Navascape Products: RR#2, 1081 Rife Road, Cambridge ON N1R 5S3, Ph: 800 265 6496 b. Navascape Products: 7447 Bren Road, Mississauga ON L4T 1H3, Ph: 800 562 8490 B. The segmental retaining wall units shall be solid concrete interlocking units with a [split rock] [tumbled] [manufactured smooth] face appearance as follows: C. GRANDE® Wall 375 Standard Unit GRANDE® Wall 750 Standard Unit GRANDE® Wall 1125 Standard Unit GRANDE® Wall 438 Coping Unit GRANDE® Wedge Standard Unit GRANDE® Wedge Coping Unit [1000 x 375 x 200 mm high] [39.4 x 14.76 x 7.87” high] [1000 x 750 x 200 mm high] [39.4” x 29.52” x 7.87” high] [1000 x 1125 x 200 mm high] [39.4” x 44.29” x 7.87” high] [1000 x 438 x 200 mm high] [39.4 x 17.24 x 7.87” high] [380/250 x 312.5 x 200 mm high] [14.96/9.84 x 12.3 x 7.87” high] [380/250 x 312.5 x 100 mm high] [14.96/9.84 x 12.3 x 3.93” high] Wallstone™ Standard Unit Wallstone™ Double Unit Wallstone™ Triple Unit Wallstone™ 12” Coping Unit Wallstone™ 18” Coping Unit [300 x 200 x 100 mm high] [11.81 x 7.87 x 3.93” high] [300 x 400 x 100 mm high] [11.81” x 15.75” x 3.93” high] [300 x 600 x 100 mm high] [11.81” x 23.62” x 3.93” high] [300 x 200 x 100 mm high] [11.81 x 7.87 x 3.93” high] [450 x 200 x 100 mm high] [17.72 x 7.87 x 3.93” high] Meet the following physical requirements [For GRANDE and GRANDE Wedge] a. Average compressive strength of three coupons cut from units to be greater than 30 MPa with no individual coupon below 27 MPa when tested in accordance with ASTM C140. b. Average absorption of three specimens to be less than 6% with no individual unit greater than 7% when tested in accordance CSA A165-Series. c. Average loss of three specimens less than 600 g/m2 (17.7 oz/yd2) after 50 freeze-thaw cycles immersed in a 3% saline solution when tested in accordance with OPSS 1352. [For Wallstone ] a. Average compressive strength of three coupons cut from units to be greater than 21 MPa with no individual coupon below 18 MPa when tested in accordance with ASTM C140. b. Average absorption of three specimens to be less than 8% with no individual unit greater than 10% when tested in accordance CSA A165-Series. c. Average loss of three specimens less than 1000 g/m 2 after 50 freeze-thaw cycles immersed in a 3% saline solution when tested in accordance with OPSS 1352. Segmental Retaining Walls (Gravity) Page 3 Navascape Products | MasterFormat Specifications 2.02 PRODUCT SUBSTITUTIONS A. Substitutions: No substitutions permitted. 2.03 FOUNDATION SOIL A. The foundation shall be native undisturbed on-site soil. The foundation shall be examined and approved by the geotechnical engineer prior to the placement of the base materials. B. Should the foundation soil not be suitable for bearing loads to be applied, the Engineer shall provide guidance on the removal and replacement of suitable soil to meet the bearing requirement. 2.04 BASE MATERIAL A. Provide base materials as follows: a. The footing material shall be non-frost susceptible, well-graded compacted granular material manufactured from crushed rock conforming to grading requirements in Table 1. [Depth required behind wall according to retaining wall designer’s requirements]. b. Compaction density of base material should be no less than 100% Standard Proctor Modified Dry Density according to ASTM D 698 [according to retaining wall designer’s requirements]. c. Sieve according to [CSA A23.2A]. Table 1 Grading Requirements for Base Material OPSS 1010 - Granular ‘A’ Sieve Size 6” (150 mm) 1” (26.5 mm) ¾” (19 mm) ½” (13.2 mm) 3/8” (9.5 mm) No. 4 (4.75 mm) No. 16 (1.18 mm) No. 50 (0.300 mm) No. 200 (0.075 mm) 2.05 Percent Passing 100 100 85 to 100 65 to 90 50 to 73 35 to 55 15 to 40 5 to 22 2 to 8 BACKFILL MATERIAL A. Provide backfill material as follows: a. The backfill material shall be a non-frost susceptible, free draining sand and gravel material conforming to the grading requirements in Table 2. [Depth required behind wall according to retaining wall designer’s requirements]. b. Compaction density should be no less than 98% Standard Proctor density according to ASTM D 698 [per retaining wall designer’s requirements]. c. Sieve according to [CSA A23.2A]. Segmental Retaining Walls (Gravity) Page 4 Navascape Products | MasterFormat Specifications Table 2 Grading Requirements for Backfill Material OPSS 1010 – Granular ‘B’ Sieve Size 6” (150 mm) 1” (26.5 mm) ¾” (19 mm) ½” (13.2 mm) 3/8” (9.5 mm) No. 4 (4.75 mm) No. 16 (1.18 mm) No. 50 (0.300 mm) No. 200 (0.075 mm) 2.06 Percent Passing 100 50 to 100 20 to 100 10 to 100 2 to 65 0 to 8 ACCESSORIES A. Provide accessory materials as follows: a. Drainage Pipe i. Manufacturer: [Specify manufacturer] ii. Material: [Specify material] iii. Material Standards: a. Size: [Specify diameter of pipe] b. Perforation / Covering: [Specify flow rate / fabric wrapped] c. Outlet distance: [Specify distance between outlets] Note: The need for a geotextile is left to the designer. When certain backfill materials are used that does not meet the above standard, a geotextile may be mandatory. A qualified civil engineer shall decide whether the geotextile is required for the project. Delete below article if geotextile is not to be used. b. Geotextile i. Manufacturer: [Specify manufacturer] ii. Material: [Specify material] iii. Material Standards: a. Apparent Size Opening: [Specify] b. Weight of material: [Specify weight of material] c. Coefficient of permeability: [Specify] PART 3 EXECUTION 3.01 ACCEPTABLE INSTALLERS A. [Specify acceptable retaining wall contractors] 3.02 EXAMINATION A. Acceptance of Site Verification of Conditions: a. General contractor shall inspect, accept and certify in writing to the retaining wall installation subcontractor that site conditions meet specifications for the following items prior to installation of the retaining wall. i. Verify that sub-grade preparation, compacted density and elevations conform to the specified requirements. ii. Provide written density test results for soil sub-grade materials to the Owner, General Contractor and retaining wall installation subcontractor. iii. Verify location, alignment, and elevations of retaining wall, [attachments], [utility structures], [and drainage inlets]. Segmental Retaining Walls (Gravity) Page 5 Navascape Products | MasterFormat Specifications B. Do not proceed with installation of granular base and retaining wall blocks until sub-grade soil conditions are corrected by the General Contractor or designated subcontractor. 3.03 PREPARATION A. The Contractor shall retain an Engineer to oversee all aspects of construction of the retaining wall. The items to inspect include, but are not limited to the following: a. Verify that sub-grade preparation, compacted density and elevations conform to the specifications. The site must be stripped of all topsoil, unstable or unconsolidated materials to the grades indicated. Construction will not proceed until the sub-grade has been inspected and approved by the Engineer. b. Verify that aggregate base materials, thickness, compaction, surface tolerances, and elevations conform to the submitted Shop Drawings. Base material to extend a distance equal to the depth of the granular base in front of the intended face of wall and behind the back of the base block. c. Verify that the drainage pipe behind the wall has been installed and outlet according to the Shop Drawings. d. Verify the retaining wall units are placed in accordance with the Shop Drawings. e. Verify that the aggregate backfill materials, thickness, and compaction conform to the Shop Drawings. f. Verify the type, placement and location of the geotextile is in accordance with the Shop Drawings. B. The certifying engineer must furnish the contractor with a letter indicating the retaining wall has been constructed in accordance with the Shop Drawings. 3.04 INSTALLATION A. The foundation soil shall be excavated or filled as required to the grades and dimensions shown on the Contract Drawings. The foundation soil shall be proof rolled and examined by the inspecting engineer to ensure it meets the minimum strength requirements indicated on the Shop Drawings. If unacceptable foundation soil is encountered, the contractor shall excavate the material out to the satisfaction of the Engineer and replace with suitable material under the direction of the Engineer. B. [Place geotextile]. C. Spread the granular base evenly over the geotextile and compact to standard as indicated on the Shop Drawings. D. Level the granular base to level of underside of base block to +/- 3 mm [+/- 1/8”] off approved final base grade elevations. Care should be taken to ensure the base material is level front to back and side to side. E. Place the base row of retaining wall units as indicated on Shop Drawings. Care should be taken to ensure the blocks are aligned correctly and are level side to side and back to front and are in complete contact with the base material. F. Retaining wall units above the base course shall be placed according to the desired batter configuration. Units shall be places such there is a minimum 1/3 running bond between successive courses. G. Place drainage pipe behind the retaining wall units in the location indicated. The pipe should be laid at a gradient to ensure adequate drainage to outlet sources. H. Before the placement of the successive courses, the top of the laid units shall be swept clean to ensure no dirt, concrete or foreign particles interfere with the placement of the next course. I. Backfill between the back of the retaining wall units and the undisturbed native soil with the backfill material and compact. At no time should the units be stacked higher than two courses above the backfill material. J. Backfill should be placed in lifts no greater than 100 mm (4”) thick before compacting. Segmental Retaining Walls (Gravity) Page 6 Navascape Products | MasterFormat Specifications K. Compaction equipment should not get closer than 300 mm (12”) retaining wall during compaction of backfill material. Larger compaction equipment should be kept a minimum 1 m (40”) behind wall. L. Cut units as required with a masonry saw. M. Retaining wall shall be finished at the top with coping units. [For Wallstone the coping unit shall be secured to the course below it using a concrete adhesive]. 3.05 FIELD QUALITY CONTROL A. The following are the maximum allowable deviations from the Contract Drawings: a. b. c. d. Vertical Control - +/- 32 mm [1 ¼”] over a 3000 mm [10 ft] distance Horizontal Location Control - +/- 32 mm [1 ¼”] over a 3000 mm [10 ft] distance Rotation – 2 degrees from published batter Bulging – 25 mm [1”] over a 3000 mm [10 ft] distance B. All retaining wall units shall be free of defects that would interfere with the proper placement of the unit or would significantly affect the structural integrity of the structure. 3.06 PROTECTION A. After work in this section is complete, the General Contractor shall be responsible for protecting work from damage due to subsequent construction activity on site. END OF SECTION Segmental Retaining Walls (Gravity) Page 7