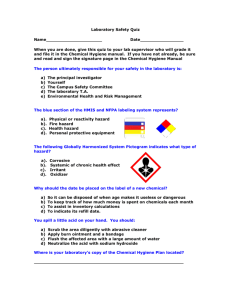

Chemical Hygiene Template - Environmental Health & Safety

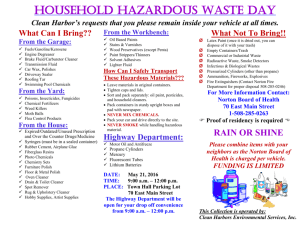

advertisement