Production and Cost Analysis: Part II

advertisement

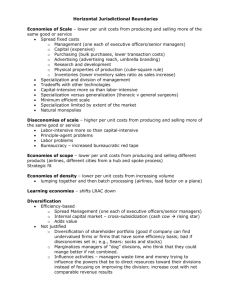

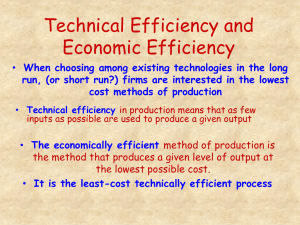

Production and Cost Analysis: Part II Chapter 10 Making Long-Run Production Decisions • To make their long-run decisions, firms look at costs of various inputs and the technologies available for combining these inputs, and then decide which combination offers the lowest cost. Making Long-Run Production Decisions • The firm makes long-run decisions on the basis of the expected costs, and expected usefulness, of inputs. Technical Efficiency and Economic Efficiency • Technical efficiency is a situation in which as few inputs as possible are used to produce a given output. • Technical efficiency is efficiency that does not consider cost of inputs. Technical Efficiency and Economic Efficiency • The economically efficient method of production is that method that produces a given level of output at the lowest possible cost. • It is the least-cost technically efficient process. Determinants of the Shape of the Long-Run Cost Curve • The law of diminishing marginal productivity does not hold in the long run since all inputs are variable in the long run. Determinants of the Shape of the Long-Run Cost Curve • The shape of the long-run cost curve is due to the existence of economies and diseconomies of scale. A Typical Long-Run Average Total Cost Table Total Costs Quantity of Labor 11 12 13 14 15 16 17 18 19 20 $381 390 402 420 450 480 510 549 600 666 Total Cost Total Costs = Average Total of Machines TCL + TCM Costs = TC/Q $254 260 268 280 300 320 340 366 400 444 $635 650 670 700 750 800 850 915 1,000 1,110 $58 54 52 50 50 50 50 51 53 56 A Typical Long-Run Average Total Cost Curve Costs per unit $64 62 60 58 56 54 52 50 48 Average total cost Minimum efficient level of production 11 12 13 14 15 16 17 18 19 20 Quantity Economies of Scale • There are economies of scale in production when the per-unit output cost decreases as output increases when all inputs are changeable. • In real-world production processes, economies of scale are extremely important at low levels of production. Economies of Scale • An indivisible setup cost is the cost of an indivisible input for which a certain minimum amount of production must be undertaken before the input becomes economically feasible to use. Economies of Scale • Indivisible setup costs create many realworld economies of scale. • The cost of a blast furnace or an oil refinery is an example of an indivisible setup cost. Economies of Scale • Because of the importance of economies of scale, business people often talk of a minimum efficient level of production. Economies of Scale • The minimum efficient level of production is the amount of production that spreads setup costs out sufficiently for firms to undertake production profitably. Economies of Scale • The minimum efficient level of production will be at the beginning of the constant returns portion of the average cost curve—where average total costs are at a minimum. Economies of Scale • The minimum efficient level of production is reached once the size of the market expands to a size large enough so that firms can take advantage of all economies of scale. Diseconomies of Scale • Diminishing marginal productivity refers to the decline in productivity caused by increasing units of a variable input being added to a fixed input. Diseconomies of Scale • Diseconomies of scale refer to decreases in productivity which occur when there are equal increases of all inputs (no input is fixed). – Diseconomies of scale occur on the right side of the graph of the long-run average cost curve where it is upward sloping, meaning that average cost is increasing. Diseconomies of Scale • As the size of the firm increases, monitoring costs generally increase. • Monitoring costs are those incurred by the organizer of production in seeing to it that the employees do what they are supposed to do. Diseconomies of Scale • Loss of team spirit can contribute to diseconomies of scale. • As the size of the firm increases, team spirit or morale generally decreases. • Team spirit is the feelings of friendship and being part of a team that brings out peoples’ best effort Constant Returns to Scale • Constant returns to scale is where longrun average total costs do not change as output increases. • It is shown by the flat portion of the LRATC curve. Economies and Diseconomies of Scale Costs per unit $64 62 60 58 56 54 52 50 48 Economies of Scale Constant returns to Scale Diseconomies of Scale Average total cost 11 12 13 14 15 16 17 18 19 20 Quantity Importance of Economies and Diseconomies of Scale • Economies and diseconomies of scale play important roles in real-world long-run production decisions. Importance of Economies and Diseconomies of Scale • The long-run and the short-run average cost curves have the same U-shape, but the underlying causes of these shapes differ. Importance of Economies and Diseconomies of Scale • Economies and diseconomies of scale account for the shape of the long-run total cost curve. Importance of Economies and Diseconomies of Scale • The assumption of initially increasing and then eventually diminishing marginal productivity (as a variable input is added to a fixed input) accounts for the shape of the short-run cost curve. The Envelope Relationship • In the long run all inputs are flexible, while in the short run some inputs are not flexible. • As a result, long-run cost will always be less than or equal to short-run cost. The Envelope Relationship • In the short run the firm faces an additional constraint: all expansion must proceed using only the variable input. • These additional constraints increase cost. The Envelope Relationship • The envelope relationship explains that: – At the planned output level, short-run average total cost equals long-run average total cost. – At all other levels of output, short-run average total cost is higher than longrun average total cost. Envelope of Short-Run Average Total Cost Curves Costs per unit LRATC 0 SRMC1 SRATC4 SRATC1 SRMC2 SRMC4 SRATC2 SRATC3 SRMC3 Q2 Q3 Quantity Entrepreneurial Activity and the Supply Decision • Profit is what underlies the dynamics of production in a market economy. • The expected profit per unit must exceed the opportunity cost of supplying the good for a good to be supplied. Entrepreneurial Activity and the Supply Decision • The supplier’s expected economic profit per unit is the difference between the expected price of a good and the expected average total cost of producing it. Entrepreneurial Activity and the Supply Decision • Cost curves do not become supply curves through some magic process. • To move from cost to supply, entrepreneurial initiative is required. Entrepreneurial Activity and the Supply Decision • An entrepreneur is an individual who see an opportunity to sell an item at a price higher than the average cost of producing it. Entrepreneurial Activity and the Supply Decision • Entrepreneurs organize production. • They are the ones who visualizes the demand and convinces the individuals who own the factors of production that they want to produce those goods. Entrepreneurial Activity and the Supply Decision • The entrepreneur also must convince demanders that what the entrepreneur is producing is what the demanders want. Entrepreneurial Activity and the Supply Decision • Without entrepreneurs there would be little supply because there would be no one to recognize and act on demand potential. Entrepreneurial Activity and the Supply Decision • By allowing entrepreneurs to earn profit, market economies encourage people to channel their drive into supplying material goods. Entrepreneurial Activity and the Supply Decision • Cost enters into these decisions as a cutoff since entrepreneurs who do not cover their costs generally do not stay in business. Entrepreneurial Activity and the Supply Decision • The greater the difference between price and average total cost, the greater the entrepreneur’s incentive to tackle the organizational problems and supply the good. Using Cost Analysis in the Real World • Some of the problems of using cost analysis in the real world include the following: – – – – Economies of scope Learning by doing and technological change Many dimensions Unmeasured costs Economies of Scope • The cost of production of one product often depends on what other products a firm is producing. Economies of Scope • There are economies of scope when the costs of producing goods are interdependent so that it is less costly for a firm to produce one good when it is already producing another. Economies of Scope • Firms look for both economies of scope and economies of scale. • Economies of scope play an important role in firms’ decisions of what combination of goods to produce. Economies of Scope • Globalization, by allowing firms to segment the production process, has made economies of scope even more important to firms in their production decisions. Learning by Doing and Technological Change • Production techniques available to realworld firms are constantly changing because of learning by doing and technological change. • These changes occur over time and cannot be accurately predicted. Learning by Doing and Technological Change • Learning by doing means that as we do something, we learn what works and doesn’t, and over time we become more proficient at it. Learning by Doing and Technological Change • The concept of learning by doing emphasizes the importance of the past in trying to predict performance. • The experienced failed manager is preferable to the rookie. Learning by Doing and Technological Change • Many firms estimate worker productivity to grow 1 to 2 percent a year because of learning by doing. Learning by Doing and Technological Change • Technological change is an increase in the range of production techniques that provides new ways to producing goods. Learning by Doing and Technological Change • Technological change offers an increase in the known range of production. Learning by Doing and Technological Change • Whenever learning by doing or technological change occurs, the cost curve shifts down since the same output can be produced at a lower cost. Learning by Doing and Technological Change • In some industries such as the computer business, technological change is occurring so fast that it overwhelms all other cost issues. • Technological change occurs in lowtech businesses as well. Learning by Doing and Technological Change • Moore's law states that the cost of computing will fall by half every 18 months. – As the price of computer chips falls, other industries are affected as well. Learning by Doing and Technological Change • In many businesses, the effect of learning by doing and technological change on prices is built into the firm's pricing structure. – Firms may price low in the expectation of lower costs due to learning by doing and technological change. Many Dimensions • Most decisions that firms make involve more than one dimension. • The only dimension in the standard model is the level of output. • Good economic decisions take all relevant marginal costs and benefits into account. Many Dimensions • The important thing to remember in using the standard model is the reasoning, not the specific model. Unmeasured Costs • The relevant costs as defined by economists are not the costs found in a firm’s books. • Economists include opportunity costs while accountants use explicit costs that can be measured. Economists Include Opportunity Cost • Economists insists on including the business owner’s opportunity cost. • The business owner’s opportunity cost includes forgone income that the owner could have earned by spending his or her time in another job. Economic Versus Accounting Depreciation • Economic depreciation differs from accounting depreciation. Economic Versus Accounting Depreciation • In measuring the costs of depreciable assets, accountants (and the IRS) insist on using historical costs—what a depreciable item costs in terms of money actually spent for it—as the cost basis. Economic Versus Accounting Depreciation • If the depreciable asset increased in value, accountants would still use the historical cost basis while an economist would count its increased value as revenue. The Standard Model as a Framework • Despite its limitations, the standard model provides a good framework for cost analysis. • It can be expanded to include real-world complications. Production and Cost Analysis: Part II End of Chapter 10