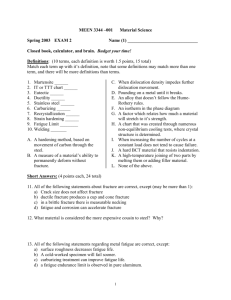

Exam 1 Review

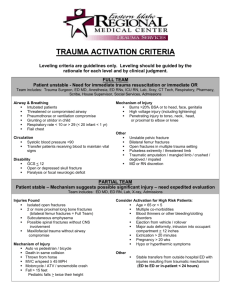

advertisement

MatSE 259 Exam 1 Review Session 1. Exam structure – 25 questions, 1 mark each 2. Do NOT forget to write your student I.D. on the answer sheet 3. Exams are sent to UTS for machine grading – please mark your answers clearly. No credit will be given if the machine cannot decipher your score Steel designation AISI-SAE numbering system for steels XX XX Percent carbon (wt) x 100 Alloy content For example, 5060 has ??? Aluminium alloy designation Numbering system for Al alloys not the same as steels Number 1xxx 2xxx 3xxx 4xxx 5xxx 6xxx 7xxx 8xxx Major alloy addition Cu Mn Si Mg Mg & Si Zn other Numbering system also includes heat treatments – see website Changing Mechanical Properties • C content in steel • Alloying elements • Heat treatment - annealing, normalizing, tempering… • Mechanical working - cold rolling, hot rolling, STRUCTURE changes Phase Diagrams Differentiate between “phase” and “state”. Phase: A phase is a homogenous part of a system that has uniform physical and chemical characteristics. Phase diagram is a plot showing the relationship between temperature, composition and the quantities of phases in a system. On a phase diagram, you should be able to understand simple heat treatments, like the T6 studied in class. For example, Al 2024-T4. Mechanical properties Tensile testing • Elastic deformation – Plastic deformation – Yield • Hooke’s Law Hardness testing • Penetration by indenter under load • Types – Rockwell, Brinell, Vickers, Knoop, Mohs • Hardness-strength conversion Mechanical properties (contd.) Impact Toughness testing • Charpy and Izod • Ductile-to-brittle transition Creep testing • Primary, secondary, tertiary • Steady-state creep rate Fatigue testing • S-N curves • Fatigue limit, fatigue strength, fatigue life Mechanical properties (contd.) Fracture Toughness testing • Pre-cracked specimen • Large Kc ductile fracture, small Kc brittle fracture Fractures • Investigation of the fracture surface for the origin of crack: “Chevron’’ markings, striations, beachmarks • Be able to recognize ductile fractures/ brittle fractures/ intergranular fractures/ transgranular fractures/ fatigue fractures….. Crystal Structures Most common crystal structures for metals are: - Cubic close-packed - Hexagonal close-packed Close-packed unit cells - A2 (“Body centered cubic”) • close-packed; most densely packed • Slip planes are the most densely packed planes in these structures. Dislocations • Dislocations move along slip planes – ductility • It is possible to plastically deform a material which contains dislocations Dislocations (contd.) • The ability of a metal to deform depends on the ability of the dislocation to move • Restricting dislocation motion will strengthen the material. Methods: - solid solution hardening - grain size reduction - strain hardening (work hardening) - precipitation hardening (age hardening or aging) Dislocation Interactions • With each other - annihilate - entangle - form generators • With grain boundaries - disappear - pile-ups Resolved Shear Stress R=(F Cos )/(A Cos )=CosCos The critical resolved shear stress is the least stress required to cause slip. T4 Temp Time Natural Aging T4 (contd.) Properties Al 2024-O Tensile Strength Yield Strength 179 MPa 75.8 MPa 26000 psi 11000 psi Al 2024-T4 Tensile Strength Yield Strength 469 MPa 324 MPa 68000 psi 47000 psi Charpy/Izod Bar Close-packed unit cells