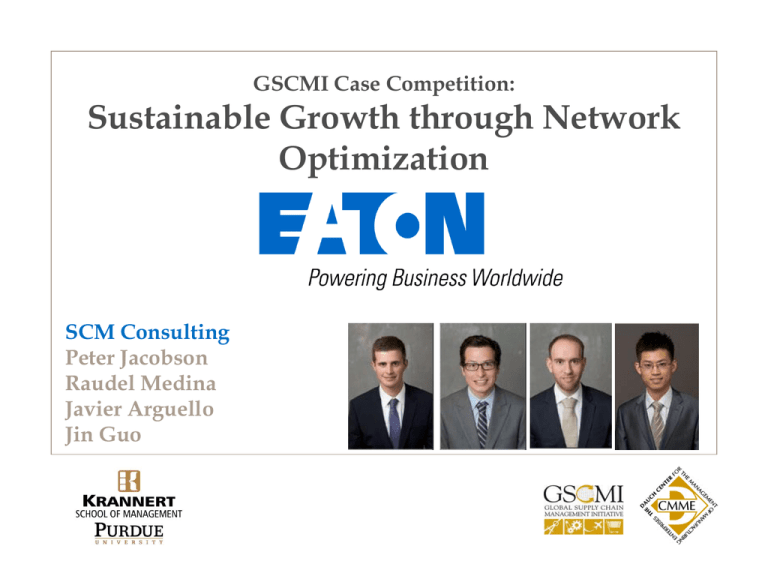

GSCMI Case Competition - Krannert School of Management

advertisement

GSCMI Case Competition: Sustainable Growth through Network Optimization SCM Consulting Peter Jacobson Raudel Medina Javier Arguello Jin Guo West CMSC’s struggle Supply uncertainty • Undeveloped external supply network in west • Warehouses (W34, W87) interests not aligned CSMCs • CDC interests aligned to CSMCs, but located in east • Custom products require custom components Demand uncertainty • Customer orders are difficult to forecast • Customers demand short lead times • Product nature is innovative (highly customized) Problem Recommendation Analysis (Peter Jacobson) Supply chain is misaligned with goals of CSCMs in west High shipping costs High inventory holding costs Implementation GSCMI 2013 Case Competition Risks & 2 Contingencies Eaton’s goals in redesign Short-term Long-term Reduce premium freight frequency Minimize overall inventory level Problem Recommendation (Peter Jacobson) Analysis Ensure sustainable growth Implementation GSCMI 2013 Case Competition Risks & 3 Contingencies An agile supply chain (Peter Jacobson) Reduce supply uncertainty • Establish a dedicated warehouse to serve Electrical Division in the west • Collaborative replenishment: vendor managed inventory • Improve information sharing (EDI) • Review / redesign Kanban System • Develop supply network in west Reduce demand uncertainty • Coordination with customers • Postponement • Product design: Standardized components/multi-functional parts Problem Recommendation Analysis Implementation GSCMI 2013 Case Competition Risks & 4 Contingencies The Solution (Raudel Medina) • Leasing a warehouse in the west coast • Consignment parts • Review/Redesign the Kanban System • Broaden external supplier base • Standardized components/multifunctional parts Problem Recommendation Analysis Implementation GSCMI 2013 Case Competition Risks & 5 Contingencies Solution Analysis (Raudel Medina) • W87 provides small amounts of parts to CMSC sites • “Other” sites account for the intersite CMSC inefficient product move • Costs of leasing reduces the investment in a permanent site Problem Recommendation Analysis Implementation GSCMI 2013 Case Competition Risks & 6 Contingencies Warehouse Location • 7 locations = 62% of Premium Shipments (Javier Arguello) 62% Premium • Los Angeles and Phoenix minimize transportation costs • W87 is located at Los Angeles • Phoenix has lower leasing cost • Lower labor costs • More opportunities to expand Problem Recommendation Analysis Implementation GSCMI 2013 Case Competition Risks & 7 Contingencies Eaton’s Success Plan Problem Recommendation Analysis (Jin Guo) Implementation GSCMI 2013 Case Competition Risks & 8 Contingencies Other factors (Jin Guo) Uncertain Economic Conditions Economic slow-down will negatively impact the demand for Eaton’s services Short-term Lease Contract Project Management Team Wrong supply chain management team may make the problem worse even with a good supply chain strategy Select the right team in charge of the project Coordination Coordination between implementing the new system and satisfying the demand from all sites Well-designed process to execute the new strategy Problem Recommendation Analysis Implementation GSCMI 2013 Case Competition Risks & 9 Contingencies Summary – Q&A Control Inventory Long-term Growth Reduce premium freight GSCMI 2013 Case Competition 10 Backup GSCMI 2013 Case Competition 11 Transportation calculations GSCMI 2013 Case Competition 12 Transportation calculations GSCMI 2013 Case Competition 13 Warehouse leasing Source: http://www.loopnet.com/ GSCMI 2013 Case Competition 14 Arizona vs California GSCMI 2013 Case Competition 15 Shipment trends over year 1,600,000 1,400,000 1,200,000 1,000,000 800,000 600,000 400,000 200,000 Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Month (2013) Orders from CSMC sites 15,000,000 14,000,000 13,000,000 $ $ Orders by premium ship 12,000,000 11,000,000 10,000,000 9,000,000 8,000,000 Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Months (2013) GSCMI 2013 Case Competition 16 Eaton’s financials GSCMI 2013 Case Competition 17