Drilling Simulator : Rock Layer Modelling and Rock Cutting

advertisement

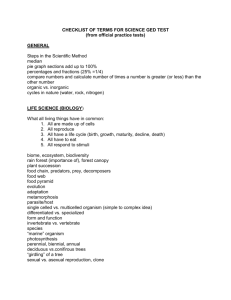

Drilling Simulator : Rock Layer Modelling and Rock Cutting Movement Warsidi#1 # Electrical Engineering Department, School of Electrical and Informatic Engineering, Bandung Institute of Technology Bandung, West Java, Inconesia 1warsidi72@yahoo.com Abstract—Drilling Simulator is one of the oil drilling process simulation is developed based on the concept of interaction between the bit with layers of rock that is in the earth's surface. Drilling Simulator is the representation of objects in the world of rock layers of 3D graphics. The aims of this study is explain the patterns of interaction between the bit and the rock layers that exist (game object) in the Drilling Simulator. The interaction pattern that is expected to provide an overview of the formation pressure distribution (Pformasi), fluid pressure or the pressure of drilling mud (Pmud), and rate of penetration (ROP). Environment development of GUI (graphical user interface) Drilling Simulator based on 3D modeling and applying 3D game engine using the unity engine. The main visual device that is used to describe a 3D model and its environment is a monitor used to display user interaction with 3D environmets in Drilling Simulator. Tests performed included testing the interaction between the bit and the layers of rock that will provide value to the rate of penetration (ROP), formation pressure (Pformasi), and mud drilling pressure (Pmud). Key words: rate of penetration, user, Drilling Simulator, cutting. I. INTRODUCTION Oil well drilling technology and gas have been developed in two decades (1950-1970). Each of the petroleum industry has a goal to be able to explore and exploit oil fields and gas wells. Oil well drilling process can be divided into two groups: well drilling exploration and exploitation drilling. Exploration drilling aimed to determine the geological structure of the surface layer of the earth and to determine the possible discovery of hydrocarbons (petroleum) on the surface of the earth. Exploitation wells while drilling acquisition aims to increase the production of hydrocarbons (petroleum), known as enhanced oil recovery(EOR) methods[3]. The components of the petroleum drilling consists of a power system, hoisting system, fluid circulation system, rotary system, and the model layer of rock beneath the earth's surface and the movement of cutting rock drilling results in the earth's surface to the outer surface of the earth is affected by the density of rock cutting , the density of drilling mud, rheology properties of drilling mud, pipeline velocity (annular) drilling. Computer simulation is a computer program or computer network to simulate the abstract models of a system of particles[7]. According to the Millheim [6] simulator is a device or equipment that mimics some of the physical processes or operations at several large degree. Simulation is not related to equipment and numerical or mimic the logic in some processes, operations or phenomena. Drilling Simulator is a computer program designed to simulate the physical processes that occur in petroleum drilling. Realization of drilling and well engineering simulation created using 3D computer graphics, real-time simulation and sound effects. II. BASIC THEORY Earth composed by three main types of groups of igneous rocks (igneous rocks), sedimentary rocks (sedimentary rocks) and metamorphic rocks (metamorphic rock). this grouping When drilling a well located at a shallow sedimentary rock layers of the formation pressure can be assumed 1 as hydrostatic pressure. Hydrostatic pressure is defined as the weight of the fluid at a certain depth is defined by equation (II.1). ...(II.1) P Po formasigh with P the formation terkanan in Pascal (Pa), formasi is a mass of rock types in kg/m3, g is in the earth's gravitational acceleration 9.81 m/s2, h and the depth of formation (rock layers) from a ref erence point in meters. By using the assumptions above, the amount of pressure can be written for drilling fluid (drilling mud) at a certain depth as in equation (II.2). ...(II.2) P Po mud gh with P the formation terkanan in Pascal (Pa), formasi is a mass of rock types in kg/m3, g is in the movement speed of cutting rock drilling results are influenced by these factors: (1) the density of cutting rock (rock layers), (2) the density of drilling mud, (3) drill pipe annular velocity, (4) angle hole drilling. Cutting speed of the rock removed from the drilling bit affects the efficiency and speed of penetration. Observations about the ability of a numerical study of the mud to lift the rock cutting depends on the type of flow, laminar flow or turbulent flow. In the turbulent flow, the velocity profile is more flat and the reverse will not happen as shown in Figure II.1 below. earth's gravitational acceleration 9.81 m/s2, h and the depth of formation (rock layers) from a ref erence point in meters. Factors that influence the ROP[1] is the type of bit, the characteristics of the formation (rock layers), the properties of drilling fluid (drilling mud), bit operating conditions (heavy bit and bit rotational speed), use of dental bits, and bits of hydraulic pressure. In drilling with tricone bit, there are four factors that affect the drilling process, the mathematics can be expressed by equation (II.3). …(II.3) ROP f (WOB , N , C, Q) [5] With ROP the rate of penetration, WOB is the weight on bit, N rotation speed is in bits, C is a bit high gear, and Q the volume of air flow is used. Rock drilling capability means ROP is given to the rocks by the drilling bit. In 1971 Bauer[5] formulated on the ROP as expressed by equation (II.4). WOB N …(II.4) ROP 61 28 . log S c D 300 with S c is uniaxial compressive strength (UCS) in MPa, D is bit diameter in meter. In 1994, equation (II.4) is modified by Bauer into equation (II.5). ROP 5.7105 RF 28 log0.145S c WN …(II.5) with RF the penetration factor of the rock. Table II.1 The penetration factor of the rock ( RF ) No 1. 2. 3. Rock Name limestone shale sandstone UCS(MPa) RF 220 25 50 61 200 200 Cutting rock drilling is the result of the drilling process is performed bit. The magnitude of the Figure II.1 Differences in laminar flow and turbulent flow[4] In laminar flow, rise and fall of rock cutting advanced by Pigott by applying Stokes law, as in equation (II.6) and equation (II.7) below[4]. 148 d c2 s m vls ...(II.6) Equation (II.6) for cutting a spherical rock. As for the cutting flat shaped stones according to equation (II.7) 57 .5d c2 s m vls …(II.7) With vls the maximum slip velocity (terminal) of rock cutting on the laminar flow (ft / min), d c the rock cutting diameter (in), is the density of mud and rock cutting is the density (lb / gal), the sludge viscosity (cp), 148 and 57.5 is the constant dimensional coefficient including grit (cutting a flat rock about 40% faster than the ball-shaped rock cutting). Turbulent velocity obtained from the equation changes Rittinger. William and Bruce have used equation (II.8) and equation (II.9) below [4]. d m …(II.8) vc 170 c s m Equation (II.8) for cutting a spherical, while equation (II.9) for cutting flat shaped rocks. t d c s m …(II.9) vc 133 c dc m 2 With vc the cutting slip velocity in turbulent flow (ft/min), and tc the ratio of the thickness and dc diameter rock cutting.The value v c must be corrected for the influence of the wall, or rock cutting itself from an annular region. This is achieved by the empirical expression as in equation (II.10) below. vc vts …(II.10) d 1 c da with vts the cutting slip velocity on turbulent flow (ft/min) and d a the hydraulic diameter anullus. Annulus diameter ( d a ) can be expressed by equation (II.11). d a d lub ang d pipa …(II.11) with the borehole diameter in meters and the diameter of the drill pipe being used. Reynolds number is a number that is used to check the type of fluid flow, laminar flow, turbulent flow or transitional flow between laminar flow and turbulent flow. Reynolds number is expressed by equation (II.12) below. [4] 928 vd Re ...(II.12) with Re the Reynolds number, is the density of the fluid (lb / gal), v is the average velocity of flow (ft / s), d is the diameter of the pipe (in), is the fluid viscosity(cp). With the following conditions: (1) if <2000, then the type of flow is laminar flow, (2) if> 4000, then the type of flow is turbulent flow, (3) if 2000 << 4000, then the type of flow is a flow transition between laminar flow to turbulent flow. III. DESIGN AND ANALYSIS A. Specifications To analyze and design the system behavior Drilling Simulator, based on system specifications are as follows: 1. user can select and use the menu on the Drilling Simulator; 2. user can menentukkan magnitude of the density of drilling mud (rho_mud), the magnitude of the rotational speed (RPM); 3. user can menngganti bit; 4. the interaction between the bit with a layer of rock that is expressed by the magnitude of ROP; 5. game object created, such as the pipe model, the model layer of rock, rig models, models of rolling cutter bits, drill collar and models. Specification of requirements modeling and its interaction with the rock layers on the simulator drilling bits as follows. (1) The simulator can model the layers of rock drilling in the oil drilling area consists of sandstone rock layer model, the model layer of shale, limestone layer models that have a variable such as density of rock (rho_rock), depth (h), pressure (P_formation), the fluid pressure or drilling mud (P_mud) and data robustness rock (K_batuan), (2) Drilling Simulator to show an association between ROP bit values to the model layer of rock being drilled (ROP depends on the layer of rock). (3) Drilling Simulator can display the value of the formation pressure (Pfor), drilling mud pressure, depth, time of drilling, the value of WOB on the panel are available. Specification modeling of rock layers and their interaction with the system bit Drilling Simulator as follows. (1) Model rock layer in the form of a 3D model with a thick layer of rock layers of the model includes some sandstone, limestone rock layer model, and model layers of shale rock. (2) Model rock layer contains the physical data such as density of rock (rho_sandstone = 2650 kg/m3), rho_limestone = 2710 kg/m3, and rho_shale = 2500 kg/m3), depth of bedrock (h), rock hardness (usandstone = 10000000 Pa, Pa ulimestone = 250000000, and ushale = 2000000 Pa) and rock penetration factor (Rfsandstone = 200, Rflimestone = 61, and Rfshale = 200). (3) Model rock layer affect the bit value of ROP, the ROP is calculated using equation (II.7). ROP 5.7105 RF 28 log0.145S c WN (4) Model rock layer determines the pressure of the rock formations (Pfor) and the drilling fluid pressure (pmud). Pressure value formations (rock layers) can be calculated using equation (II.1) while the value of the drilling mud pressure can be calculated using equation (II.2). P Po formasigh P Po mud gh Specification modeling the movement of rock cutting bits from the bottom to the surface of the Earth Simulator in Drilling system as follows. (1) Cutting rock is modeled as a 3D model in a spherical shape with a size that matches the size of rocks in the drill. 3 (2) The process of breaking rock layers depends on the UCS and RF rocks (depending on the value of ROP) of each layer of rock being drilled. (3) The model of rock cutting speed can be determined by determining the Reynolds number as in equation (II.13). (4) Speed of rock cutting bits from the bottom up to the surface of the earth can ditentukkan by using equation (II.8) for laminar flow model and equation (II.10) to model the turbulent flow. Figure III.2 Model layer of limestone rock B. Analysis To realize the system specifications that will be designed in this study required supporting components. (1) Software for modeling and 3D animation Required to create 3D models such as models of rock layers, drilling rig models, model pipe, drill colar models, models of blow out preventer (BOP) and the model bit. (2) Software for the creation and graphic design Required to make a rock texture, texture pipeline. (3) Software for the game engine used Drilling is required to make the system simulator. C. Design Modeling of rock layers include three-dimensional modeling and object modeling physically. Model rock layer that covers the model layer is made of rock shale, sandstone rock layer models, and models of limestone rock layers with different layer thickness variation. Figure III.2 Model layer of sandstone rock Modeling the interaction between the model and bit of rock layers can be illustrated by Figure III.4 below. Picture III.4 model the interaction between the models with a bit of rock layers Design use case diagram for Drilling Simulator as shown in Figure III.5. <<include>> play <<include>> <<include>> tutorial Or physical modeling involving data for layers of rock shale, sandstone, and limestone that includes a data density of the rock consists of shale density (rho_shale), the density of the sandstone (rho_sandstone), and the density of limestone (rho_limestone) as in Figure III.1, Figure III.2 and Figure III.3 below. scene viewdrillmovement <<include>> scenetutorial <<include>> help <<include>> scene help <<include>> <<include>> about scene about exit Figure III.5 Use case drilling simulator To determine the relationship between rock layers with ROP may be illustrated by the following algorithm below. Figure III.1 Model layer of shale rock Start if any collision between bit with layer rock model then Cek collision.gameObject.layer == 9 then Rock layer is ”shale” Count formation pressure Pfor = Po+rho_shale*g*h Count ROP; else 4 Cek collision.gameObject.layer == 10 maka Rock layer is ”sandstone” Count formation pressure Pfor = Po+rho_shale*g*h Count ROP; else Cek collision.gameObject.layer == 10 maka Rock layer is ”limestone” Count formation pressure Pfor = Po+rho_shale*g*h Count ROP; Finish Figure III.6 image panel on the drilling simulator models E. Implementation In the implementation phase dilakukkan following steps: 1. Implementation of the model into the engine 2. Program Code Implementation (coding) This stage is the implementation phase of the program code (coding) to build the interaction between the user with a Drilling Simulator and the interaction between the bit with the model of rock layers. a. Program code for the interactions between the bits of rock layers to the model include: • display the slider to adjust the rotation speed, • Print a magnitude of ROP, • display the time of drilling, • show the type of rock layers, • display the depth of drilling (bit), • displaying rock formation pressure, • displays pressure drilling fluid (mud), • display the WOB. b. Program code for collision detection. c. Program code for loading sound. 3. Object into the implementation stage of the game engine: a. makes modeling in 3D Max; b. export the model into a format *. FBX; c. import the model into the engine; d. add a mesh collider (for collision detection); e. add script (coding) for each behavior designed. F. Testing The following is the initial view Drilling Simulator using the game engine Unity 3.4. Figure III.5 The initial view of drilling simulator Testing is done to the parameters of the design and implementation can be measured very well. Here is a table mapping functionality in modeling the movement of rock layers and rock cutting. III.7 picture below is a display parameter Drilling Simulator run time. Figure III.7 Image display parameters of drilling simulator Table IV.1 The test results Spesification Rock model Implementation + Test Output layer Yes The influence of rock type on the pressure rock formations and the ROP Rock cutting movement model No View the movement of rock particles from the bottom bit to the surface (not available) Model rock layer can accept input from user No - Rig model yes Rig display Pipe model yes Pipe display Drill Collar model yes DrillCollar display 5 IV. CONCLUSIONS AND SUGGESTIONS A. Conclusions The conclusion to be drawn from this study are as follows. (1) The design and implementation of the model can provide a layer of rock stones lithologi. (2) For this type of rock layers of different models will give different values of ROP. (3) The more models of rock layers, the more varied the value of ROP bit and the movement of rock cutting. Evolution Fourth, Brooks/Cole, forth edition, Belmont, 2006. [8] Prassl, Wolfgang F., Drilling Engineering, Departement of Petroleum Engineering, Curtin University of Technology. B. Suggestions Some suggestions that may be applied further on the results of this study are as follows. (1) Make the model more layers of rock. (2) Drilling Simulator created a 3D model of the movement are not yet cutting rock, resulting in the development can then use the particle method for modeling the movement of the cutting system of the lower bits of rock to the surface of the earth. (3) The parts of Drilling Simulator is yet to be made can be developed further as a model the flow of drilling mud (drilling fluid models) and models of petroleum reservoirs. REFERENCES [1] Bourgoyne Jr, Adam T, Millheim, Keith K, Chenevert, Martin E., dan Young Jr, F.S., Applied Drilling Engineering, SPE, Richardson, TX, 1991 [2] Bruno, Michael, Han, Gang, and Honeger, Claudia, Advanced Simulation Technology for Combined Percussion and Rotary Drilling and Cutting Transport. Terralog Technologies, USA, 2005. [3] Darley,H.C.H, Gray,George R, Composition and Properties of Drilling and Completion Fluids, Gulf Publishing Company, fifth edition, Houston, 1988. [4] Gatlin, Carl, Petroleum Engineering Drilling and Well Completions, Prentice Hall Inc, Englewood Cliffs,N.J, 2006. [5] Gokhale,B.V, Rotary Drilling and Blasting in Large Surface Mines, CRC Press. London, 2011. [6] Jose Gregorio Salas Safe, Drilling Optimization Using Drilling Simulator, Texas A&M University, Texas, 2004. [7] Monroe, James S., Wicander, Reed, The Changing Earth Exploring Geology and 6