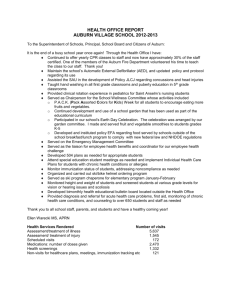

UTC proposal draft 10-10-11

advertisement