Proposal Layout - RP-Jobs

advertisement

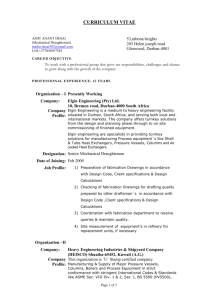

Ahmad Mohammad Abd el-AzeemAbd el-Mo'men Static Equipment Engineer Personal Information:Mobil: 010 9677 9337 e-mail: engalahmedy@gmail.com st Birth Day: September 1 , 1985 Gender: Male. Address: Giza, Al-Aiyat. Nationality: Egyptian. Military Status: Exempted. Marital Status: Married. Language:Arabic & English Professional memberships / Registration: Engineers Syndicate 54/06045 Academic Information (2003-2007):- Mechanical Power Department, Faculty of Engineering, Al-Azhar University, Cairo, Egypt. Bachelor's Degree: Excellent with honor grade. Graduation Project: «B.Sc. New Technologies in Operation, Control, and Maintenance of Pumps & Reciprocating Compressors ». Graduation Project Mark: Excellent. Work Experience:QualificationHighlightsandKey Achievements Feb. 2013 – Sep. 2013 Experience in Designing pressure vessels, heat exchangers & air cooled heat exchanger according to ASME VIII Div.1, TEMA STD, API 660 and API 661. Hard working skills, ability to work under stress, interpersonal skills, communication and analytical skills & planning and organization skills. CB&I Company Position:Static Equipment Engineer Responsibilities: Perform all aspects of mechanical design of static equipment. Preparing and reviewing Equipment requisitions in accordance with project requirements. Performing technical evaluations of incoming quotations from bidders and checking completeness of scope and compliance with specifications. Reviewing vendor data. Cooperate and co-ordinate with project disciplines. Projects:- Longford Gas Conditioning Plant Client: ExxonMobil Development Company Location: Longford, Australia Tasks: Full Mechanical datasheets, scope of supply - based on ASME Section VIII Div.1 &API 661, Engineering specifications and procedure – enquiry requisition, technical offers review and suppliers query list, technical bid tabulation and bids evaluation for:- a- Fifteen Pressure Vessels Div.1. b- Air Cooled Heat Exchanger Ingleside Ethylene Project Client: Occidental Chemical Corporation Location: Ingleside, TX Tasks: Preparing of Mechanical datasheets based on ASME Section VIII Div.1, Site Data & Available Utilities Spec. and Ingleside Ethylene Project Specs (pressure vessel, fireproofing and painting system)for 25th pressure vessels. September 2013 Page 1 of 4 Ahmad Mohammad Abd el-AzeemAbd el-Mo'men Static Equipment Engineer Apr. 2008 – Feb. 2013 PETROJETCompany (The Petroleum Projects & Technical Consultation Company) Position:Static Equipment Design Engineer Responsibilities: Issuing the mechanical calculation of pressure vessels according to ASME code section VIII division-1 using PV Elite and Compress software. Issuing the general arrangement and details drawing of pressure vessels. Preparing the material requisition list according to ASME code sec. II part A. Issuing the thermal calculation for TEMA heat exchangers using HTRI software. Issuing the mechanical calculation for TEMA heat exchangers according to ASME code sec. VIII using PV Elite software. Issuing the construction drawings for TEMA heat exchangers. Projects: El-Wastani Plant Increasing Capacity 200MMSCFD Project Client: WASCO/Enppi Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with TEMA standard, API 660 and ASME section VIII division-1 and section II part A for the following equipment:1. Four Heat exchangers. 2. Three tube bundles. West Harbor Expansion Project 3425-200 Client: Pharaonic Petroleum Company, PhPC / Enppi Location: Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for two pressure vessels. Seth Development Project Client: Petrobel Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for two pressure vessels. Three Phase Separator Project Client: Amerya Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for two pressure vessels. Crude Distillation Unit Project Client: Amerya Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requiSeptember 2013 Page 2 of 4 Ahmad Mohammad Abd el-AzeemAbd el-Mo'men Static Equipment Engineer sition list in accordance with ASME section VIII division-1 and section II part A for one pressure vessel. WDDM, Phase VII, Main Compression Project Client: Burullus Gas Company Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for one pressure vessel. PTW New Oil Treatment Train Project Client: Petrobel Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for two pressure vessels. Abu El-Gharadik Plant Project Client: GUPCO/Enppi Location: RasGhareb, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for one pressure vessel. Kharir Development Project Client: TOTAL/Enppi Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for two pressure vessels. MTA Polystyrene Project Client: Enppi/E-styrenics Location: Alexandria, Egypt Tasks: Preparing the mechanical design calculation, fabrication drawings and material requisition list in accordance with ASME section VIII division-1 and section II part A for six pressure vessels. Dec. 2007- Mar. 2008 September 2013 Working in Arab Steel Fabrication Company (ASF) ELSWEDY GROUP for four months. Cairo – Egypt Position: Maintenance Engineer. Responsibilities: (Steel fabrication, galvanization, towers and high mast factories). The skills I had got there are as the following: 1- Gearing systems and power transmission systems. 2- Hydraulic and pneumatic systems. 3- Construction and manufacturing for new machines. 4- Welding machines (SAW, MIG) automatic &semi-automatic. 5- Flame cutting machines (Plasma, Photocell & CNC). Page 3 of 4 Ahmad Mohammad Abd el-AzeemAbd el-Mo'men Static Equipment Engineer Computer Skills Highlights PV Elite, Compress, HTRI, AutoCAD, Auto Desk Inventor, MS Office (Word / Excel / Power Point). Knowledge ASME Section II, (Materials). ASME Section VIII Division 1, (Rules For Construction of Pressure Vessels). ASME B16.5, (Pipe Flanges and Flanged Fittings). ASME B16.20, (Metallic Gaskets for Pipe Flanges). ASME B16.47, (Large Diameter Steel Flanges, NPS 26 through NPS60). ASME B36.10M, (Welded and Seamless Wrought Steel Pipe) TEMA, (Standards of the Tubular Exchanger Manufacturer Association). API 660, (Shell and Tube Heat Exchangers for General Refinery Services). API 661, (Air Cooled Heat Exchangers for General Refinery Services). Special Courses/ Training September 2013 ASME Sec. VIII Div.1 (Society of Mechanical Engineers) 5/2008. ASME Sec. VIII Div.1 (American University in Cairo) 11/2008 Heat Exchangers Design, Construction and Maintenance. (OGS) 7/2010. Letters and Correspondence Writing Skills (Modern Management Center) 8/2008. Management Training Program (Modern Management Center) 9/2008. Managerial Skills Developing For Engineers (PEMEC) 5/2009. Page 4 of 4