PLASTICS

advertisement

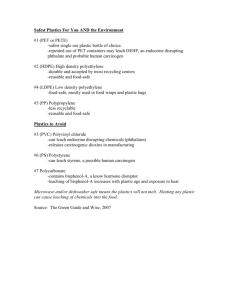

ASSALAMUALAIKUM & GOOD MORNING FOR MUSLIM: ALWAYS FOLLOW THE WAY OF ISLAM COMPLETELY FOR NON MUSLIM: ALWAYS SET GOAL BEFORE WORKING TOWARDS IT PLASTICS TYPES OF PLASTIC There are 2 types of plastic that is: a) Thermoplastics - A polymer that softens ans melts gradually when heated and it can be reshaped when still warm. b) Thermosets - A polymer that can’t be reshaped after manufacture Thermoplastics polyethylene, polypropylene, polystyrene & polyvinyl chloride (PVC) most common thermoplastics Any object made from thermoplastic can be remolded into a new shape. Thermoplastics creep considerably more than thermosets, particularly at higher temperature Can be used for light structural properties Polystyrene has specific gravity of 1.05 It tensile strength is low, less than 48.5 MPa Modulus of Elasticity is low has good water resistance and dimensional stability and inexpensive (cheap) But it possesses poor heat resistance, limited weather resistance. It is brittle and lacks toughness Pure polystyrene that is crystal clear used for storage container and cups. Polystyrene and expanded polystyrene used in tiles, packaging, containers, foams and housewares. Foamed polystyrene used in poured-inplace concrete wall systems & as insulation boards for foundation walls, masonry and wood walls and roofing. Polystyrene Sheeting In-situ concrete flooring on 300mm of Expanded Polystyrene insulation. Polystyrene Block ( Usage In Construction ) Polyvinyl Chloride (PVC) Specific gravity about 1.39 It’s made from monomer, vinyl chloride Tensile strength low nearly like polystyrene It’s an excellent insulator Used in raincoats and shower curtains Extensively used in floor tiles, electric cables, flexible sheeting, hoses, pipes, expansion joint filler, ,moldings, luggage, decorative wall coverings, Multi-Lock Industrial Warehouse Floor Tile Made Using PVC PVC Vinyl Floor Tile PVC pipe Polyethylene Specific gravity of 0.92 Tensile strength very low, less than 13.8 Mpa Modulus of Elasticity is very low It’s tough, weather-resisting plastic & durable Has excellent electrical properties Has favorable chemical resistance It’s common application is as polyethylene bags Polyethylene used in manufacture of films, sheets, pipings, tanks, foams, electrical conduit and moldings. Polyethylene films & sheets used as dampproof courses, membranes & curing membranes Polyethylene Plastic Polyethylene Bags Product Made Using Polyethylene Polypropylene Has low specific gravity like polyethylene Low modulus of elasticity lightest material of all thermoplastics Has a higher softening point and shinier Good heat resistance but degrades under exposure to sunlight Has good abrasion resistance and hardness Used for pipes, sheets, geomembranes Polypropylene Sheets Protector Pack Geomembranes Made Using Polypropylene Polypropylene Pipe Fittings Acrylics Crystal clear in natural form has good weather resistance and ease of forming Tensile strength higher than other thermoplastic material Used in light fittings, skylights, screen doors, paints and adhesives Acrylic Acrylic Shower Base, Screen and Door Thermosets Most popular thermosets are unsaturated polyester, epoxides, phenol-formaldehyde and polyurethane. Polyester used in manufacture of fiberglass product and composite materials Phenol-formaldehyde used in lavatory seats, electrical fittings and equipment decorative laminates. Rope Made Using Polyester Beaker Made Using Phenol Formaldehyde Advantages Of Plastic It has high damping capacity ( ability to absorb part of the vibrational energy) that makes it suitable in application where vibration is encountered. Excellent water resistant. - It have low water-absorption properties making suitable as impervious membrane layers that could prevent movement of water. Application in foundation, water supply installation, for concrete curing It’s lower prices have contributed to the universal application of plastic. Low cost Plastics have a favorable strength / weight ratio. It has low density (less than half of the concrete and 1/7 steel) Since plastic is light, it present ease in handling, transportation, storage and assembly. Most plastics are generally maintenance free and have good corrosion resistance Thermal insulation of plastic is higher than other material. - used extensively as wall & ceiling insulation in both cast-in-place (as foamed insulation) and precast constructions (as rigid insulation) Plastics can be molded to any shape and pattern. Plastic products come in variety of colors & textures. - Manufactured plastics have good surface finish and may not require maintenance. - It’s availability in many color & texture makes it commonly used for floor, wall tiles & countertops. Plastics can be manufactured with consistent quality. Disadvantages Of Plastic It has low stiffness and strength which make it can be used for load bearing construction - It is subject to creep, that is the increase in deformation, under load, with time - Rate of creep of plastic higher than concrete - Creep deformation increases with stress level - Therefore, plastics become dimensionally unstable under load. Plastics are combustible/flammable material. Plastics emits toxic gases such as carbon monoxide during burning. Plastics may emit dense smoke, thereby making escape more difficult. - Shouldn’t be used in exits areas of building such as around stairways and corridors Expensive and subject to uncertainties arising for the oil price fluctuations. Acoustical insulation of plastic is poor. Modified Plastic Addition substances can be added to the plastic during manufacturing process to improve the properties of the plastic. Plasticizers to soften the plastic & make it easier for shaping. Antioxidants prevent degradation by light and heat. Colorants give color to plastic Fibers to improve strength of thermoplastic & thermosets Fiber Reinforced Plastic For application requiring very high tensile strength Fibers added not only increase stiffness & strength but also reduce shrinkage, improve abrasion resistance & provide dimensional stability to plastic resin. This is a light weight, high strength & corrosion resistance material. In civil engineering application for pedestrian bridges, bridge repair and as prestressing tendons. ALWAYS SAY THANKS AS A SIGN OF APPRECIATION TO OTHERS WHO HELP YOU GOOD LUCK