A Permit-Required Confined Space

advertisement

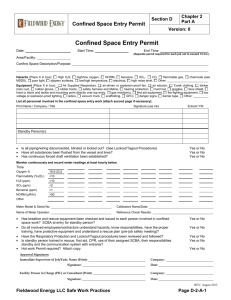

Permit-Required Confined Space Entry 29 CFR 1910.146 Objectives • Understand Legislation Developed by Government Agencies • Identify and Use Those Regulations • Identify a Potentially Hazardous Confined Space Organizations • ANSI • – American National Standards Institute – Consensus Standards for Atmospheric Hazards NIOSH – National Institute for Occupational Safety and Health – Documents Incidents – Develops Guidelines for Safe Work Organizations (continued) • OSHA – Occupational Safety and Health Administration – Began Looking at Confined Spaces in 1975 – Cited Under General Duty Clause – Proposed Standard Released June 1989 Permit-Required Confined Spaces 29 CFR 1910.146 • Became Law April 15, 1993 • Employers MUST – Characterize the Confined Space – Provide a Permit Allowing Entry – Supply Personal Protective Equipment When Required • Excludes Agriculture, Construction, and Shipyards Permit-Required Confined Spaces 29 CFR 1910.146 A Confined Space is... • Large Enough and Configured Such That an Employee Can Enter and Perform Assigned Work • Has Limited or Restricted Means for Entry or Exit (e.g., Tanks, Vessels, Silos, Storage Bins, Hoppers, Vaults, and Pits) • Is Not Designated for Continuous Employee Occupancy Permit-Required Confined Spaces 29 CFR 1910.146 A Permit-Required Confined Space... • • • Contains or Has Potential to Contain a Hazardous Atmosphere Contains a Material That Has the Potential for Engulfment Internal Configuration of Inwardly Converging Walls or Sloping and Tapering Floor • Contains Any Other Recognized Serious Safety or Health Hazard Permit-Required Confined Spaces 29 CFR 1910.146 Engulfment... • Surrounding and Capture of a Person • Liquid or Finely Divided (Flowable) Solid • Can Cause Filling or Plugging of Respiratory System Via Aspiration • Can Exert Enough Force on Body to Cause Death by Strangulation, Constriction, or Crushing Permit-Required Confined Spaces 29 CFR 1910.146 Immediately Dangerous to Life or Health (IDLH)... • Immediate or Delayed Threat to Life • Causes Irreversible Adverse Health Effects • Interferes With the Ability to Escape from a Permit Space Permit-Required Confined Spaces 29 CFR 1910.146 IDLH Conditions... • Flammable Gas, Vapor, or Mist >10% of LFL • (LEL) Airborne Combustible Dust > LFL Dust Obscures Vision at a Distance of 5 ft. or less • Oxygen < 19.5 % or > 23.5% • Exposures in Excess of OSHA’s PELs Employer’s Responsibilities • Determines Whether Permit-Required Confined Spaces Exist (Appendix A - Flow Chart) • Informs Employees and Posts Warning Signs • Prevents Entry If Employees are Not to Work in PRCS Employer’s Responsibilities (continued) • Develop and Implement a Written Permit Entry • • • Program May Use Alternate Procedures If a Non-Permit Space is Reconfigured, Reevaluation of the Space is Required Must Inform Contractors and Use Permitting Program DANGER CONFINED SPACE ENTER BY PERMIT ONLY! Permit-Required Confined Space ELEMENTS OF THE PROGRAM • Prevent Unauthorized Entry • Identify and Evaluate the Hazards Prior to Entry (Appendix B- Who Can Do This, & How) • Develop Safe Entry Procedures – Acceptable Entry Conditions – Isolating the Permit Space – Purging, Inerting, Flushing, or Ventilating – Barriers to Protect from External Hazards Permit-Required Confined Space (PRCS) Equipment • Testing and Monitoring Equipment • Ventilating Equipment • Communications Equipment • Personal Protective Equipment Permit-Required Confined Space (PRCS) Equipment (continued) • Lighting • Barriers and Shields • Ladders and Other Entry/Egress Equipment • Rescue and Emergency Equipment Permit-Required Confined Space ELEMENTS OF THE PROGRAM (continued) • Evaluate Space Before and During Work • Provide at Least One Attendant Outside for the • • • Duration of Entry Operations Multiple Space Response Procedures Designate Active Roles Rescue and Emergency Response Procedures Permit-Required Confined Space ELEMENTS OF THE PROGRAM (continued) • System for Preparation, Issuance, Use and • • • • Cancellation of Permits Procedures for Multiple Employer Worksites Procedures for Closing Space Review of Entry Operations Review of Program Permit-Required Confined Space (PRCS) • • • • Permit System Entry Permit Training Other Appendices – Appendix C: Example Situations – Appendix D: Example Check List & Permit – Appendix E: Sewer System Entry Permit-Required Confined Space The Permit 1. DATE:____ TIME:____ A.M../P.M. 2. VESSEL # 3. JOB # 4. LOCATION: 5.DESCRIPTION OF WORK: 6.PHYSICAL HAZARD ASSESSMENT: Engulfment, Electrical, Steam, Augers, Chain Drives etc.. 7. CORRECTIVE MEASURES: Physical Disconnects, Lockout / Tagout etc.. 8. ATMOSPHERIC ASSESSMENT: Oxygen, LEL, CO, H2S (Other) 9. Instrument # 10. Calibration Date: 11. Name of Operator: 12. Substance 13. P.E.L. 14. Actual 15. Oxygen 16. < 19.5% or > 23.5% 17. Other 18. LEL > 10% 20. 21. Carbon Monoxide (CO) 22. 50 ppm 23. Other 24. Hydrogen Sulphide (H2S) 25. 10 ppm 26. Other 27. PPE 28. Respirators 29.Rescue Equipment 30. Other 31. Other 32. Other 33. Names of entrants, Attendants, and Entry Supervisors: 34. Time work / shift completed: (35.) Problems / concerns 36. Emergency contact: Other OSHA Regulations Hazard Communication – 29 CFR 1926.59 – MSDS – Training – Labeling – Written Program Control of Hazardous Energy Sources – 29 CFR 1926.417 & 1910.147 – “Lock Out/Tag Out” – De-Energize ALL Sources of Energy – Written Program Permit-Required Confined Spaces Administrative Controls Permit Space Entry Program Learning Objectives • Describe the Guidelines for a Permit-Required • Confined Space Program Identify Conditions Which Allow the Use of Alternate Procedures General Requirements • • • • A Written Permit Space Program Authorized Personnel Confined Space Evaluation Procedures Acceptable Entry Conditions and Procedures PRCS Program The Entry Permit Shall Identify: 1) The Permit Space to be Entered. 2) The Purpose of the Entry. 3) The Date and Duration. 4) The Authorized Entrants. 5) The Attendants. 6) The Entry Supervisor. 7) The Hazards of the Space to be Entered. 8) Measures to Isolate and Eliminate the Hazards Before Entry. 9) The Acceptable Entry Conditions. 10) The results of Initial and Periodic Tests with Initials of Testers. PRCS Program The Entry Permit Shall Identify: 11) The Rescue and Emergency Services That Can Be Summoned. 12) The Communication Procedures Used By Entrants and Attendants. 13) Equipment such as Testing, Communication and Emergency Equipment. 14) Any Other Information Necessary, In Order To Ensure Employee Safety. 15) Any Additional Permits Such As a Hot Work Permit. Authorized Entrant Duties • • • • Knows Hazards, Symptoms, and Consequences Proper Use of Equipment Communicate With Attendant Exit Promptly From PRCS When Necessary Attendant Duties • Knows Hazards, Symptoms, and Consequences • Awareness of Behavioral Effects of Exposure • Continuously Identifies Number and Identity of Entrants • Remains Outside of PRCS • Communicates With Entrants Attendant Duties • • • • • Monitors Entrant & Surrounding Activity Summons Rescue If Needed Keeps Unauthorized Persons Away From PRCS Performs Non-Entry Rescues Performs Only Attendant Duties Entry Supervisor Duties • Knows Hazards, Symptoms, and • • Consequences Verifies Performance of Permit Testing, Procedures and Equipment Terminates PRCS Entry and Permit Entry Supervisor Duties • Verifies Availability and Communication • • With Rescue Services Removes Unauthorized Personnel Determines Compliance With the Entry Permit Rescue and Emergency Services Using Employer’s Personnel... • Trained in PPE and Rescue Equipment • Trained in Rescue and Authorized Entrant Duties • Practice Rescues Once Every 12 Months – Simulated With Mannequins or People – In Actual PRCS • Trained in CPR and Basic First Aid – At Least 1 Member of Rescue Service Holding Current Certification Rescue and Emergency Services Outside Rescue Service... • Must Be Informed of Hazards Prior to Arrival • Must Have Access to All Spaces to Assess and Allow for Practice of Rescues Rescue and Emergency Services Non-Entry Rescue... “Retrieval Systems or Methods Shall Be Used Whenever an Authorized Entrant Enters a PRCS” – – Unless Equipment Increases Risk or Would Not Assist Rescue – – Attached to Mechanical Device or Fixed Point Outside Space Chest or Full Body Harness, Center of Back Near Shoulder or Above Head; Wristlets ONLY if Harness is Infeasible or Greater Hazard MSDS Must Be at Worksite and Furnished to Medical Facility Treating Exposed Entrants Testing and Monitoring Appendix B • Evaluation Testing – Any Hazards – Prior to Entry – Technically Qualified Professional • • • • • OSHA Consultation Service CIH Registered Safety Engineer CSP Verification Testing Testing and Monitoring Appendix B • Duration of Testing • Testing Stratified Atmospheres – Atmospheric Envelope of 4 ft. in Direction of Travel and to All Sides – Rate of Progress of Entrant Slowed to Accommodate Instrument Sampling Speed and Response Time Hot Work Permits Defined As: Written Authorization to Perform Operations Capable of Providing a Source of Ignition (Such As Welding, Cutting, or Brazing) Required for: Hot Work in Grain Handling Facilities and Any Other Combustible/ Explosive Areas Hot Work Permits General Provisions • Remove Fire Hazards & Combustibles • Guard the Work • Guard Openings to Other Areas • Maintain Fire Extinguishers Hot Work Permits General Provisions • Maintain Fire Watch • Written Permit Authorization • Protect Floors & Walls • Protect Drains, Dusts, and Pipes Alternate Procedures Can be used if... • • • • ONLY Hazard is an Actual or Potential Hazardous Atmosphere And Can Demonstrate That Continuous Forced Air is Sufficient to Maintain the Space as Safe Data is Developed to Support the Above A Permit Program is Followed During Data Collection Alternate Procedures (continued) • Hazard from Removing Entrance Cover is • • Eliminated Entrance is Made Safe to Prevent Accidental Falls Atmospheric Testing for – Oxygen – Flammability – Toxic Contaminants Alternate Procedures (continued) • No Hazardous Atmospheres Develop While • Employee is In Space Continuous Forced Air Ventilation is Used – No Entry Until Safe – Remains Until Everyone Has Left Space – Air is From a Clean, Safe Source • Periodic Testing Alternate Procedures (continued) • If A Hazard Develops – Evacuation of Space – Evaluation as to the Source – Protection of Employees Prior to Re-entry • Documentation – Date, Location, Signature of Person Certifying – Certification Made Prior to Entry and Available to each Employee Alternate Procedures (continued) At Issue -“Elimination” of Hazards • • If the Stated Conditions Are Met, the Employer Does Not Have to Implement –Personnel Duties –PRCS Program –Rescue –Permit System –Emergency Services –Entry Permit OSHA Compliance Letter (10/12/95) Interprets the Elimination Provision: “… If the Non-Atmospheric Hazards Were Permanently Eliminated, the Alternate Procedures Could Subsequently Be Applied…” Hazards are usually dictated by... • The material stored in the confined space. • The activity carried out in the confined space. (a particular chemical reaction) • The external environment. (a tank located near rising waters) OSHA Estimates • 224,000 establishments have permit required confined space. • 2.1 million workers enter these spaces annually. • 60% of the deaths that occur in confined spaces are the rescuers who go in after the victim. Confined Space Hazards • Chemical Hazards • Physical Hazards • Biological Hazards • Ergonomic Hazards Engulfment • The surrounding or covering of a person by a liquid or flowable solid. Death may result by suffocation, strangulation, constriction, or crushing. – Concrete – Asphalt Primary Constituents of Normal Air (Permanent Gases) Constituent Chemical Formula Molecular Weight Percent by Volume Nitrogen N2 28 78.1 Oxygen O2 32 20.9 Argon Ar 40 0.9 Water vapor content varies, but is usually the third largest constituent by volume in air. Definitions of O2 Deficient Atmosphere 29 CFR 1910.146 (PRCS) Source 42 CFR Part 84 (NIOSH Resp. Approval) <19.5% Oxygen <19.5% Content 29 CFR 1910.134(g) (Resp. Std.) 16.0%1 29 CFR 1910.94 (Ventilation. Std.) <19.5% 29 CFR 1915.11(b) (Shipyards) <19.5% ANSI Z117.1-1995 (Confined Spaces) <19.5% ANSI Z88.2-1992 (Respirator Practices) 16.0%2 ACGIH (TLV booklet) 18.0% 1 2 Letter of interpretation Oxygen partial pressure <122 mmHg. Confined space with <20.9 % O2 is IDLH, unless source of O2 reduction is understood and controlled. Oxygen-Deficient Atmospheres O2 Content Effects and Symptoms (at patm) 15-19% Decreased ability to work strenuously. May impair coordination and induce early symptoms in persons with coronory, pulmonary, or circulatory problems. 12-14% Respiration increases in exertion, pulse up, impaired coordination, perception, and judgment. 10-12% Respiration further increases in rate and depth, poor judgment, lips blue. 8-10% Mental failure, fainting, unconsciousness, ashen face, blueness of lips, nausea, and vomiting. 6-8% 8 min., 100% fatal; 6 min., 50% fatal; 4-5 min., recovery with treatment. Coma in 40 sec., convulsions, respiration ceases, death. 4-6% NOTE: Exposure to atmospheres containing 12% or less oxygen will bring about unconsciousness without warning and so quickly that individuals cannot help or protect themselves. How an Oxygen-Deficient Atmosphere Can Occur in a Confined Space 1. Consumption a) b) c) 2. Displacement a) b) c) 3. Adsorption a) Nitrogen (N2) • Colorless, odorless inert gas • Slightly lighter than air Argon (Ar) • Colorless, odorless inert gas • Heavier than air Argon (Ar) • Colorless, odorless inert gas • Heavier than air Methane (CH4) • • • • • Natural, marsh, swamp gas Colorless, odorless flammable gas Lighter than air Toxic? LEL = 5%; UEL = 15% Carbon Dioxide (CO2) • • • • • • • Colorless, odorless noncombustible gas Heavier than air Common in solid and compressed liquid forms Carbonation Inerting Organic decay (grain elevators, sewers, storage bins, wells) Fermentation (digestors, molasses pits, beer and wine vats) CO2 (cont’d) • • • • PEL = 5,000 ppm - TWA (Table Z-1) TLV/REL = 5,000 ppm - TWA; 30,000 ppm - STEL IDLH = 50,000 ppm LEL = none Carbon Monoxide (CO) • • • • • Colorless, odorless gas Slightly lighter than air Chemical asphyxiant Primary source: incomplete combustion of organic material Gasoline-fueled combustion engines CO (cont’d) • • • • • • PEL = 50 ppm - TWA TLV = 25 ppm - TWA BEI: <3.5% COHb; 20 ppm (end-exhaled air) REL = 200 ppm - STEL; 35 ppm - TWA IDLH = 1500 ppm LEL = 12.5%; UEL = 74.2% Concentration of CO Necessary to Produce Symptoms Percent ppm Effects 0.02 200 Possibly headache, mild frontal in 2-3 hrs. 0.04 400 Headache, frontal, and nausea after 1-2 hrs.; occipital after 2-1/2 to 3-1/2 hrs. 0.08 800 Headache, dizziness and nausea in 3/4 hour, collapse and possible unconsciousness in 2 hrs. 0.16 1,600 Headache, dizziness and nausea in 20 min.; collapse, unconsciousness, possibly death in 2 hr. 0.32 3,200 Headache and dizziness in 5 to 10 min., unconsciousness and danger of death in 30 min. 0.64 6,400 Headache and dizziness in 1 to2 min., unconsciousness and danger of death in 10 to 15 min. 1.28 12,800 Immediate effect; unconsciousness and danger of death in 1 to 3 min. (Source: Hamilton & Hardy) Symptoms of CO Exposure Percent* Symptoms 0-10 Shortness of breath on exertion 10-20 Tightness across forehead, slight headache 20-30 Throbbing headache 30-40 Severe headache, nausea, vomiting, collapse on exertion 40-50 All symptoms increased, pulse rate and breathing increased 50-70 Coma, interrupted breathing (Cheyne-Stokes), death * Percent saturation of Hemoglobin with CO [Blood Levels] Hydrogen Sulfide (H2S) • • • • Sewer gas, stink gas (rotten eggs) Odor threshold: 0.02 - 0.2 ppm Colorless, flammable gas Heavier than air • • • • • PEL = 20 ppm - C; 50 ppm - Peak (10 min. once) TLV = 15 ppm - STEL; 10 ppm - TWA REL = 10 ppm - C (10 min.) IDLH = 300 ppm LEL = 4.3%; UEL = 46% H2S (cont’d) • • • • • PEL = 20 ppm - C; 50 ppm - Peak (10 min. once) TLV = 15 ppm - STEL; 10 ppm - TWA REL = 10 ppm - C (10 min.) IDLH = 300 ppm LEL = 4.3%; UEL = 46% Effects of H2S Concentration ppm* Local Systemic 20 50 Irritant of conjunctival and corneal epithelium 50-100 Eye and respiratory tract irritation in 1 hr. 100-150 Slight systemic symptoms after several hrs. 150 Olfactory nerve paralysis Fatal in 8-48 hrs. 200 Pulmonary irritation and pulmonary Nervous system depression edema after prolonged exposure * Concentration by Volume Effects of H2S Concentration (cont’d) ppm* Local Systemic 250-350 Fatal in 4-8 hrs. 350-450 Fatal in 1-4 hrs. 500-600 Excitement, headache, dizziness and unconsciousness, death in 30-60 min. 600-700 Rapid collapse, death in 2-15 min. 700-2,000 Cessation of respiration, rapidly fatal * Concentration by Volume Other Toxics May arise from the: 1. Product(s) stored 2. Manufacturing processes 3. Work being performed 4. Adjacent areas Definitions • Vapor Pressure- Pressure exerted by a vapor. If a vapor is kept in confinement over its liquid so that the vapor can accumulate above the liquid, the vapor pressure approaches a fixed limit called the maximum vapor pressure. (How much the liquid wants to become a gas) • Flash Point- The minimum temperature at which a liquid gives off vapor within a test vessel in sufficient concentration to form an ignitable mixture with air near the surface of the liquid. Combustible is >100 F Flammable is <100 F 0 0 BOILING POINT IA IB 100 F 0 IC II IIIA IIIB (NFPA) (29 CFR 1910.106) Flammable/Combustible Liquid Classification Flammable (Explosive) Limits • When vapors of a flammable or combustible liquid are mixed with air in the proper proportions in the presence of a source of ignition, rapid combustion or an explosion can occur. The proper proportion is called the flammable range and is also often referred to as the explosive range. The flammable range includes all concentrations of flammable vapor or gas in air, in which a flash will occur or a flame will travel if the mixture is ignited. There is a minimum concentration of vapor or gas in air below which propagation of flame does not occur on contact with a source of ignition. There is also a maximum proportion of vapor in air above which propagation of flame does not occur. These boundary-line mixtures of vapor with air are known as the lower and upper flammable or explosive limits (LFL or UFL) respectively, and they are usually expressed in terms of percentage by volume of vapor in air. Atmospheric Pressure • Atmospheric pressure is 760 mmHg a substance with a vapor pressure of 760 mmHg is a gas at room temperature. – Water vapor pressure= 25 mmHg – Fuel oil vapor pressure= 2 mmHg – Vinyl chloride vapor pressure= (760 mmHg)(3.4) • “1300 rule” – 1300*VP= concentration just above the surface of the liquid MSDS Exercise • What color is this substance? • What type of odor does it have? • What PEL or TLV is set for this substance? • What are some of the synonyms for this substance? • What products are incompatible with this product? • What type of PPE should be worn while handling this product? • What are some of the symptoms of overexposure? • If a co-worker was overexposed to this product what information should be • • give to medical personnel? Is this substance designated as a hazardous waste by the EPA? Who might you call for more information about this product? Air Monitoring Permit-Required Confined Spaces Objectives • Describe Why the Work Environment Needs to • • Be Monitored Understand the Value of Personal, Area, and Perimeter Monitoring Identify Several Types of Monitoring Equipment Why Do Monitoring? • To Detect if Potential Hazardous Conditions Exist • To Measure Concentrations of Hazardous Substances Detection of Hazards • To Determine Whether Hazardous Materials Are • • • Present Under Normal Conditions Whether the Environment is IDLH Measure Releases During Work to Ensure Proper PPE and Work Practices Ensure That No Hazardous Materials Remain After a Release Hazards In The Air • • • • • Oxygen Deficiency/Enrichment Explosive Atmospheres Toxic Chemicals Radioactivity Biological Hazards Oxygen Oxygen Enriched 23.5% Oxygen Deficient 19.5% 16.0% 14.0% 6.0% Minimum for Safe Entry Impaired Judgment & Breathing Faulty Judgment Rapid Fatigue Difficulty in Breathing Death in Minutes Explosive Limits Too Rich UEL Combustible LEL Too Lean 10% of LEL Personal Air Monitoring • • • • PRO Accurate Measure of Actual Exposure Compares to OSHA PEL, STEL Documents Exposure Allows Appropriate PPE Selection • • • • CON Lab Analysis 1 to 14 Days No Peak or Ceiling Measures Need to Know What Exposures are Possible Preparation and Calibration Needed Prior and Following Personal Monitoring Equipment • Battery Operated Sampling Pumps – Filters - Fumes/Particles/Mists – Charcoal Tubes - Gases/Vapors – Silica Gel Tubes - Gases/Vapors • Passive Badge Dosimeters Gases and Vapors Real-Time Measurements • • • • • PRO Immediate Measures Measures Variety of Exposures Measures IDLH Situations Detects Peak Toxic and Flammable Levels Determines Ability to Enter PRCS • • • • • CON May Not Detect “Low” Levels Not Specific May False Alarm Interferences and Cross Sensitivity May Require Factory Calibration Direct Reading Instruments • • • • • Oxygen Meter Explosive Gas Meter/Combustible Gas Indicator Detector Tubes Personal Alarm Monitors Multi-Gas Analyzer/Meters Examples of Direct Reading Instruments Review • • • • Where Are Measurements Taken? What Types of Measurements Can Be Made? How Are These Measurements Used? What Are Some of the Limitations of Air Sampling? Instrumentation • O2 Meters – Use O2 Meters • Flammable Gases and Vapors – Use Combustible Gas Indicator • Toxic Air Contaminants – Use Colorimeteric Detector Tubes Combustible Gas Indicators • Used to sample vapor concentrations near and in permit spaces • Reads LEL • A reading above 10% should be considered a potentially explosive atmosphere Combustible Gas Indicators Precautions • The equipment may not respond the same to all vapors • O2 MUST BE MEASURED FIRST! Oxygen Meters • Used to sample oxygen concentrations in and near • • • confined spaces. Reads between 0-25% or 0-100% At greater than 23.5% O2, the explosion hazard increases. At less than 19.5% the space cannot be entered without a SCBA or SAR with escape pack. Oxygen Meter Precautions • Very sensitive to temperature and pressure changes. • At high concentrations of carbon monoxide, the meter may give improper readings. • Must be calibrated before every use! Colorimeteric Detector Tubes • Used to sample gas or vapor concentration in any work space. • Reads percent of the concentration in PPM. • Concentration indicated by color change or length of color stain. Detector Tube Precautions • They are not very accurate-- within 25% of the • • • real value at best. The tubes are very sensitive to temperature and humidity. Different tubes must be used for different chemicals. They are breakable. Tips To Help In Monitoring • • • • Check the accuracy of the instruments you are going to use. – Have they been recently calibrated? Always test in this order: Oxygen, Flammability/Combustibility, and Toxic Gases. Test the air from the top to bottom including all corners and spaces! Test the atmosphere frequently! Ventilation of Permit-Required Confined Spaces Comfort - General/Dilution Ventilation • Temperature and humidity regulations ASHRAE 55-1992 – Winter: 68 - 74oF – Summer: 73 - 79oF – RH: 30 - 60 % Comfort - General/Dilution Ventilation (cont’d) • Odor removal - outside air movement ASHRAE 62 - 1989 – Public bathrooms: 50 CFM/wc or 2 CFM/ft2 – Office: 15 CFM/person – Smoking lounges: 20 - 60 CFM/person Safety - General/Dilution Ventilation Fire and explosion control (1) Volume of air required to dilute the vapor from 1 gallon of solvent to 25% LEL. [1910.94(c)(6)(ii)] Dilution volume = 4(100-LEL)VV LEL VV = cubic feet of vapor per gallon of solvent (vapor volume) Safety - General/Dilution Ventilation (cont’d) Example: acetone Dilution volume = 4(100-2.5)44.0 2.5 = 6,864 ft3 air / gal acetone (70oF) Safety - General/Dilution Ventilation (cont’d) (2) Volume of air required to dilute the vapor from 1 gallon of solvent to 10% LEL. [1910.146(b)] Dilution volume = 10(100 - LEL)VV LEL Safety - General/Dilution Ventilation (cont’d) Example: acetone Dilution volume = 10(100 - 2.5)44.0 2.5 = 17,160 ft3 air / gal acetone (70oF) Ventilation Volume Calculation Ventilation volume = Dilution volume x Gallons of solvent evaporated per minute CFM = ft3 air gal solvent x gal solvent min Ventilation Volume Calculation (cont’d) Example: Acetone-thinned paint applied at rate of one gallon per minute. Paint is 40% solvent. Ventilation volume (for 25% LEL) 6,864 ft3 air gal solvent x 1 gal paint min x 0.4 gal solvent gal paint = 2,746 CFM Ventilation volume (for 10% LEL) 17,160 ft3 air 1 gal paint 0.4 gal solvent x x gal solvent min gal paint = 6,864 CFM Dilution Ventilation for Fire and Explosion • Reduce the concentration of vapors within an • enclosure to below the LEL. This concept is never applied in cases where workers are exposed to the vapor. Dilution rates for health hazard control are always applied in these instances, since the PEL is a much lower concentration than the LEL. Safety - Dilution Ventilation Q= 403(SG)(100)(C)(w) (MW)(LEL)(B) where, Q = air flow rate (CFM) required to dilute vapor concentration to safe condition 403 = conversion factor SG = specific gravity of liquid (water = 1) Safety - Dilution Ventilation (cont’d) 100 = constant to convert LEL to decimal fraction C = dimensionless safety factor which depends on % LEL necessary for safe conditions (10% LEL: C = 10, 25% LEL: C = 4 w = pints of liquid evaporated in one minute MW = molecular weight of vapor LEL = lower explosive limit (%) B = constant reflecting fact that LEL decreases at elevated temperatures (£ 250oF: B = 1, > 250oF: B = 0.7) Flammable Liquid Storage Rooms Ventilation must provide for a complete change of air within the room at least six times per hour (6 A.C. / hr). Exchanging all the air in the room is equivalent to 1 A.C. [i.e., Room volume (L x W x H) = 1 A.C.] 6 A.C. / hr = (6 x Room volume) / hr CFM = [6 x Room volume (ft3)] x 1 hr / 60 min CFM = Room volume (ft3) / 10 Health - Dilution Ventilation 403(SG)(106)(w)(K) Q= (MW)(PEL) where, Q = air flow rate (CFM) required to dilute vapor concentration to the PEL. K = dimensionless safety factor (varies from 3-10) to maintain concentration well below PEL. Higher value for high toxicity, high evolution rate, poor ventilation, and large number of exposed workers. Considerations for PRCS Ventilation • • • • • • • • Space configuration Ventilation mode (exhaust/supply) Ventilation flow rate Availability of make-up air Obstacles for ducting Availability of power sources Location of employee within space Characteristics of contaminant Achievement of Accceptable Atmospheres • Dilution - use general/forced air ventilation to • • dilute the contaminant Exhaust - use local exhaust ventilation to remove the contaminant Dilution/Exhaust - use a combination of both methods to remove the contaminant Dilution Ventilation • Introduces fresh air to space • Best when toxicity levels • • and concentrations are low Best when contaminants well distributed Requires larger air volume when contaminants generated at a point Local (Source) Ventilation • Exhausts from a localized area • Removes high concentrations • of contaminants from space Requires smaller volume of air Solutions • Inerting • Purging • Ventilation Inerting • Displacement of the atmosphere by a nonreactive gas (such as nitrogen) to such an extent that the resulting atmosphere is noncumbustible. Purging • The method by which gases, vapors, or other airborne • impurities are displaced from a confined space. Purpose is to do a complete air exchange in a confined space prior to entry. Normally, a purge is considered complete when atmospheric tests indicate the air is of suitable quality to sustain life. Inerting • Displacement of the atmosphere by a non-reactive gas (such as nitrogen) to such an extent that the resulting atmosphere is noncumbustible. Ventilation • At opening of blower 100% capacity • Blower plus 25’ of hose 78% capacity • 25’ of hose plus one 90 degree bend 67% capacity • 25’ of hose plus two 90 degree bend 56% capacity Electricity • Electricity Doesn’t Spring Into Action Until • • Current Flows Current Doesn’t Flow Until there is a Loop to and from the Transformer Current Always Returns to the Transformer that created it Electricity • Voltage Water Pressure • Ohms Resistance / Size of Water Pipe • Current Flow Rate of Water Electrical Shock • Contact with a normally energized conductor • • • • (wire). Contact with an energized conductor on which the insulation has lost it’s protective value Equipment failure, causing an open or short circuit Static Electricity Discharge Lightning Strike Cords & Corded Equipment • Do not remove ground plug • Flexible cords must Not be: Used instead of fixed wiring Run through holes in ceilings, walls, or floors Run through doorways, windows, or openings Concealed in walls, ceilings, or floors • Flexible cords may be used for: Pendants Fixture wiring Portable lamps or appliances Cranes and hoists Frequently Moved equipment Lockout/Tagout 29 CFR 1910.147 Control of Hazardous Energy Sources (Lockout/Tagout) Scope 1910.147 (a)(1)(i) • Covers servicing and maintenance of machines when unexpected startup or release of stored energy could cause injury. Application 1910.147 (a)(2)(i) • Standard applies to control of energy during • servicing and/or maintenance. Note: Servicing / maintenance during normal production operations is covered if: an employee is required to remove or bypass a guard, or an employee must place his / her body into danger zone Does not cover: 1910.147 (a)(1)(ii) • Construction, agriculture, maritime • Installations under control of electric utilities • Exposure to electrical hazards from work on, • near, or with conductors or equipment in electrical utilization installations (see Subpart S) Oil and gas drilling, and servicing Also Excluded 1910.147 (a)(2)(ii) & (iii) • Normal production operations (see Subpart O) • Work on cord and plug connected equipment • Hot tap operations, under special conditions Definitions 1910.147 (b) & (c)(7)(i)(C) *While not defined in 1910.147 (b), “other employees” are discussed in 1910.147 (c)(7)(i)(C). • Authorized Employee: Person who locks or tags • • machines / equipment to perform servicing. Affected Employee: One who is required to use machines / equipment on which servicing is performed under lockout / tagout or who must work in such an area. Other Employees: * All employees whose work operations are or may be in an area where energy control procedures may be utilized. Definitions (continued) 1910.147 (b) “Capable of being locked out” • Designed with hasp or attachment to which lock can be affixed; or, • Has locking mechanism built in; or, • Lockout can be achieved without need to dismantle, rebuild, replace or permanently alter. Definitions (continued) 1910.147 (b) • Normal Production Operations: Utilization of a • machine or equipment to perform its intended function. Servicing and/or Maintenance: Includes lubrication, cleaning or unjamming, making adjustments and tool changes, where employees may be exposed to UNEXPECTED energization, startup or release of hazardous energy. Energy Control Program 1910.147 (c)(1) • The employer shall establish a program consisting of an energy control procedure and employee training... in accordance with paragraph (c)(4) of this section. Lockout vs. Tagout • Lockout system is preferred method and shall be used when equipment can be locked out -- unless employer can show that tagout system provides full employee protection. Full Employee Protection 1910.147 (c)(3)(i) • When tagout is used on equipment which is capable of being locked out: Tags shall be attached where lockout devices would be; and, Employer must demonstrate that tagout will provide safety equivalent to lockout. Energy Control Procedure 1910.147 (c)(4)(i) • Procedures shall be developed, documented and utilized for the control of potentially hazardous energy when employees are engaged in servicing and maintenance. Energy Control Procedures must be written, unless all of the following exist: 1910.147 (c)(4)(i) exception • Equipment has no potential for stored / residual energy. • Equipment has a single energy source. • Isolation and lockout of one energy source completely • • • • deactivates equipment. Equipment is isolated from energy source & locked out. Lockout device is under exclusive control of authorized employee performing maintenance. No other hazards are created. Employer has had no related accidents. Procedures must contain: • Scope • Purpose • Authorization • Rules • Techniques to be utilized • Means to enforce compliance 1910.147 (c)(4)(ii) Materials / Hardware 1910.147 (c)(5) • Provided by employer • Singularly identified • Only devices used • Not used for other purposes • Durable • Standardized • Substantial Periodic Inspection • • • • • • 1910.147 (c)(6)(i) At least annually Performed by authorized employee (other than the one(s) using procedure being inspected). Designed to correct deficiencies. Lockout: Must review each authorized employee’s responsibilities. Tagout: Must review each authorized and affected employee’s responsibilities and additional training requirements of 1910.147 (c)(7)(ii). Employer certification required. Training 1910.147 (c)(7)(i) • Authorized Employee – Recognition of hazardous energy sources – Type & magnitude of energy in workplace – Methods for energy isolation / control • Affected Employee – Purpose / use of energy control procedure • Other Employee – Procedure – Prohibition on restarting machines or equipment Additional Training - Tagout System 1910.147 (c)(7)(ii) • Employees shall be trained in the limitations of tags, as follows: – – – – – – Warning devices only Must not be removed / bypassed / ignored Must be legible Must withstand environmental conditions May (will) evoke false sense of security Must be securely attached Employee Retraining 1910.147 (c)(7)(iii) • Provided when: – Change in job assignments – Change in machines, equipment or processes that present new hazards – Change in energy control procedures – Periodic inspection reveals, or employer has reason to believe, there are deviations in employee knowledge of procedures Specific Procedures 1910.147 (d)(1) - (6) • Lockout / Tagout procedures shall cover the following elements in the following sequence: – Preparation for shutdown – Shutdown – Isolation – Lockout / tagout device application – Release of stored energy – Verification of isolation Release from Lockout / Tagout 1910.147 (e)(1) - (3) • Prior to restoring energy, the following procedures are required: – Inspect machine and equipment – Safe positioning and notification of employees – Removal of lockout / tagout device Testing of Machines 1910.147 (f)(1) • When lockout / tagout devices must temporarily be removed for testing / positioning: – Clear machine of tools / equipment – Remove employees – Remove lockout / tagout device – Energize and test – De-energize and reapply energy control measures Outside Personnel (Contractors) 1910.147(f)(2) • On-site employer and outside employer shall • inform each other of their respective procedures. On-site employer shall ensure that his / her employees understand and comply with contractor’s procedures. Group Lockout / Tagout 1910.147 (f)(3) • Additional Requirements – Primary responsibility is vested in an authorized employee for a set number of employees. – Authorized employee must ascertain exposure status of group members. – If more than one crew is involved, coordinator needed. – Each authorized employee shall use a personal lockout / tagout device and remove it when finished. Shift / Personnel Changes 1910.147 (f)(4) • Specific procedures needed to ensure continuity of lockout / tagout protection. Lockout/Tagout Purpose - 1910.147(a)(3) This section requires employers to establish a program and utilize procedures for affixing appropriate lockout devices or tagout devices to energy isolating devices, and to otherwise disable machines or equipment to prevent unexpected energization, start-up or release of stored energy in order to prevent injury to employees. Lockout/Tagout Definitions - 1910.147(b) Affected employee: An employee whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is being performed under lockout or tagout, or whose job requires him/her to work in an area in which such servicing or maintenance is being performed. Authorized employee: A person who locks out or tags out machines or equipment in order to perform servicing or maintenance on that machine or equipment. An affected employee becomes an authorized employee when that employee’s duties include performing servicing or maintenance covered under this section. Energy isolating device: A mechanical device that physically prevents the transmission or release of energy. Lockout/Tagout Employer Responsibilities Education – Documentation: a written statement of company’s Energy Control Plan. – Employee training: to help employees in the use of the Energy Control Plan. Enforcement – Inspection: to make sure energy control procedures are being carried out. – Self-audit: a periodic review of the procedures and the program. Lockout/Tagout General - 1910.147(c) The employer shall establish a program consisting of energy control procedures, employee training and periodic inspections to ensure that before any employee performs any servicing or maintenance on a machine or equipment where the unexpected energizing, start up or release of stored energy could occur and cause injury, the machine or equipment shall be isolated from the energy source, and rendered inoperative. Lockout/Tagout Applying Energy Controls • Energy isolation and lockout/tagout are to be applied only by trained employees authorized to perform service or maintenance. • Before lockout/tagout is applied, all employees who work in the affected area must be notified. • The OSHA regulation requires that control of hazardous energy be done according to a six-step procedure. Lockout/Tagout Preparation for Shutdown - 1910.147(d)(1) Before you turn off any equipment in order to lock or tag it out, you must know: • The types and amounts of energy that power it • The hazards of that energy • How the energy can be controlled Lockout/Tagout Equipment Shutdown - 1910.147(d)(2) • Shut the system down by using its operating • • controls. Follow whatever procedure is right for the equipment, so that you don’t endanger anyone during shutdown. An orderly shutdown must be utilized to avoid any additional or increased hazard(s) to employees as a result of the equipment stoppage. Lockout/Tagout Equipment Isolation - 1910.147(d)(3) • Operate all energy-isolating devices so that the • • • equipment is isolated from its energy sources. Be sure to isolate all energy sources-secondary power supplies as well as the main one. Never pull an electrical switch while it is under load. Never remove a fuse instead of disconnecting. Lockout/Tagout Application of LOTO Devices - 1910.147(d)(4) • All energy-isolating devices are to be locked, tagged or both according to company’s • • • • • • • Energy Control Plan. Only the standardized devices supplied by your employer are to be used for lockout/tagout, and they are not to be used for anything else. Use a lockout device if you lock cannot be placed directly on the energy control. When lockout is used, every employee in the work crew must attack his/her personal lock. More than one employee can lock out a single energy-isolating device by using a multiplelock hasp. For big jobs, a lockout box can be used to maintain control over a large number of keys. If tags are used instead of locks, attack them at the same point as you would a lock, or as closed to it as possible. Fill tags out completely and correctly. Lockout/Tagout Control of Stored Energy - 1910.147(d)(5) • • • • • • Inspect the system to make sure all parts have stopped moving. Install ground wires. Relieve trapped pressure. Release the tension on springs, or block the movement of spring-driven parts. Block or brace parts that could fall because of gravity. Block parts in hydraulic and pneumatic systems that could move from loss of pressure. Lockout/Tagout Control of Stored Energy (con’t.) - 1910.147(d)(5) • • • • • • Bleed the lines and leave vent valves open. Drain process piping systems and close valves to prevent the flow of hazardous materials. If a line must be blocked where there is no valve, use a blank flange. Purge reactor tanks and process lines. Dissipate extreme cold or heat, or wear protective clothing. If stored energy can reaccumulate, monitor it to make sure it stays below hazardous levels. Lockout/Tagout Equipment-Isolation Verification - 1910.147(d)(6) Take any of the following steps that fit your company’s equipment and energy control program. • • • • • Make sure all danger areas are clear of personnel. Verify that the main disconnect switch or circuit breaker can’t be moved to the on position. Use a voltmeter or other equipment to check the switch. Press all start buttons and other activating controls on the equipment itself. Shut off all machine controls when the testing is finished. Lockout/Tagout Removing Energy Controls • Make sure the equipment is safe to operate. – Remove all tools from the work area. – Be sure the system is fully assembled. • Safeguard all employees. – Conduct a head count to make sure everyone is clear of the equipment. – Notify everyone who works in the area that lockout/tagout is being removed. • Remove the lockout/tagout devices. Except in emergencies, each device must be removed by the person who put it on. Lockout/Tagout Removing Energy Controls (con’t.) • In some workplaces, the last person to remove • his/her lock may have extra duties. – He/she may have to remove the hasp and lockout device. – Tags should be removed, signed, and turned in. – In some companies, the supervisor always removes his lock last. Follow a checklist of required steps to re-energize the system. Limitations of Tags 1910.147(c)(7)(ii) • Tags are essentially warning devices affixed to energy isolating devices, and do not provide the • • • • • physical restraint on those devices that is provided by a lock. When a tag is attached to an energy isolation means, it is not to be removed without authorization of the authorized person responsible for it, and it is never to be bypassed, ignored, or otherwise defeated. Tags must be legible and understandable by all authorized employees, affected employees, and all other employees whose work operations are or may be in the area, in order to be effective. Tags and their means of attachment must be made of materials which will withstand the environmental conditions encountered in the workplace. Tags may evoke a false sense of security, and their meaning needs to be understood as part of the overall energy control program. Tags must be securely attached to energy isolating devices so that they cannot be inadvertently or accidentally detached during use. Respiratory Protection • • The basic function of a respirator is to reduce the risk of respiratory injury due to breathing airborne contaminants. A respirator provides protection by removing the contaminants from ambient air or by supplying the wearer with an alternate source of clean breathing air. All respiratory apparatus are composed of two main parts: – the device which supplies or purifies air, – the facepiece which covers the nose and mouth and seals out the contaminants. – The first component defines what class of respirator the device is; the second determines the relative measure of protection afforded by that respirator. Respirator Program Elements 1. 2. 3. 4. 5. 6. 7. 8. Selection Medical evaluation Fit testing Use Maintenance and care Breathing air quality and use Training Program evaluation Respiratory Protection Classifications of respirators: – Air purifying respirators (APRs) • Particulate- mechanical filter • Gas and vapor- chemical cartridge • Requires knowledge of ambient concentration and Maximum Use Limit (MUL) of the respirator • APRs only clean the air, the ambient concentration of oxygen must be sufficient (19.5%) for the user Air-Purifying Respirator (APR) • An air-purifying respirator that uses a blower to force the ambient air through air-purifying elements to the inlet covering. Respiratory Protection Classifications of respirators: • Air supplying respirators (ASRs) – Provide a substitute source of clean breathing air. – The respirable air is supplied to the worker from either a stationary source through a long hose, or from a portable container. • The first type are called supplied-air respirators. • The second type are known as self-contained breathing apparatus. Supplied Air Respirator (SAR) • An atmosphere-supplying respirator for which the source of breathing air is not designed to be carried by the user. Also called airline respirator. Self-Contained Breathing Apparatus (SCBA) • An atmosphere-supplying respirator for which the breathing air source is designed to be carried by the user. QUESTIONS? THANK YOU