Respiratory Protection Training 7-15

advertisement

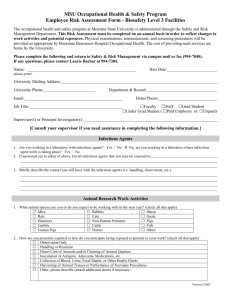

Respiratory Protection Training OSHA 29CFR1910.134 Candis Duncan Who should take this course? If your workplace has been identified as having potential respiratory hazard(s) that could result in an employee exposure • An employee exposure is an exposure to an airborne contaminant that would occur if the employee were not using respiratory protection. • What will this course cover? Respirators protect workers by preventing exposures to harmful airborne chemicals, dust/particulates, and biological agents from the air. If a respirator is worn incorrectly, it will not provide adequate protection to the wearer. This training will cover: • Clemson Respiratory Protection Program • Respirator Selection • Respiratory Hazards • Types of Respirators • Respirator Limitations • Respirator parts, inspections, seal checks • Respirator maintenance, storage, and care • Respirator Filters/Cartridges • Respirator Protection Factors • Fit Testing • Voluntary Use Clemson Respiratory Protection Program The Occupational Safety & Health Administration’s (OSHA’s) Respiratory Protection Standard requires that each employer has a written program which includes: • Medical Surveillance to determine if the employee or student is medically fit to wear a respirator. • Annual Training in the proper use (donning and removing), limitations of the respirator and storage of the respirator selected for use. • Annual Fit testing to determine that the respirator selected for use fits properly. Respirator Use Flow Chart Yes Copy of Respirator Selection and Use Worksheet Respirator Selection and Use Worksheet Department, Unit: Responsible Supervisor: Date Completed: Name of Person to Contact: Contact’s Phone and /or E-mail: RS approval date: Employee: Complete entry for job, work activity, air contaminant and/or type of respirator used if known. Send completed form to supervisor for approval. Employee should send a copy along with medical clearance forms to the Occuaptional Health Nurse (OHN). The OHN will send completed worksheet to RS if approved. Job Title Work Activity Type of Respirator Air Purifying Atmosphere Air Contaminant Supplying Facepiece (neg. Cartridge/ Type pressure, 1/2 face, full specify Canister RS Comments face, PAPR, N-95) Additional Comments: ______________________________________________________________________________________________________________________________________________ ______________________________________________________________________________________________________________________________________________ __________________________________________________________________________________________________________ Employee Signature*:______________________Date_____________ Approval from Research Safety:___________________________Date_____________ Supervisor Signature:______________________Date_____________ Approval from Occupational Health Nurse:__________________Date_____________ *Employee agrees to allow Occupational Health Nurse to notify Research Safety whether employee is approved to wear respirator. Clemson University Research Safety Why is respiratory protection needed? To provide the employee with protection from hazardous air contaminants from a variety of sources such as: •Dusts •Aerosols/mists •Metal fumes •Vapors •Gases •Biological agents •Oxygen-deficient atmospheres • What are respiratory hazards? Particles such as: • Dusts – Fine solid materials that may be caused by milling, sanding, crushing, or grinding operations. The smaller the dust, the longer it stays in the air and the easier it is to inhale. • Mists – Fine droplets of liquid produced by spraying, mixing, and cleaning operations. • Metal Fumes – Vaporized metals which rapidly cool forming fine particles that can remain suspended in the air. May occur in high-heat operations such as welding. What are the respiratory hazards? (continued) • Gases – These substances at ambient pressure and temperature are in a gaseous state and are sometimes colorless. Gases can travel far and fast from their source, often undetected. • Vapors – Substances which evaporate from liquids or solids. • Infectious Agents – Some labs can generate infectious agent aerosols. Infectious agent particles may include protozoa, fungi, bacteria, viruses, etc. How do you control respiratory hazards? The preferred method of controlling respiratory hazards is through the use of control measures such as engineering controls like ventilation, enclosures, isolation, or substitution of less toxic materials. • Other methods may include administrative controls or work practice modifications such as training workers on safe operation procedures, good house keeping, or rotating employees in and out of exposed areas • When engineering controls and administrative controls do not provide adequate protection, personal protective equipment such as respirators may be used to protect the worker. • 2 Understand the contaminants’ effect on workers’ health 1 Identify the Respiratory hazards 3 Select the appropriate respirator FOUR STEP PROCESS FOR SELECTION 4 Train in proper respirator use and care The air we breathe O2 21% Other N2 78% 1% Oxygen Deficient Atmospheres Normal oxygen level in the air is approximately 20.9%. - Symptoms of hypoxia may occur at ~16% oxygen. What may cause oxygen deficient atmospheres? – – – – Oxygen can rapidly deplete in poorly ventilated atmospheres Confined spaces such as in silos or tanks Oxygen consumption by chemical reactions, welding, or fire Chemicals may displace oxygen from the air An air-purifiying respirator will NOT protect you in an oxygen deficient atmosphere. Inhalation Toxicology Acute: – Immediate response from a single short exposure • Symptoms include coughing, dizziness, nausea, sneezing, and/or vomiting • Acute effects may assist in detection of exposure Chronic – Delayed response from repeated expsoure to low levels • May cause decreased lung function, and/or damage to other organs • Caused by workplace exposure, living environemnt or lifestyle (i.e. diet, drugs, tobacco) • A gradual process that may be difficult to detect Respirator Selection Respirator Selection Risks Oxygen Deficiency Self Contained Device Gaseous Motorized Elements Respirator with chemical Cartridge Toxic contaminant No immediate Danger to life or health Immediately dangerous to life or health Gaseous and Particulate Air line System Motorized Elements Respirator with chemical cartridge with filter for particulates Particulate Air Line System Motorized Elements Dust/Vapors Smoke HEPA Respirators Self Contained Device Air Line System Types of Respirators Air PurifyingRespirators (APR) – Remove airborne contaminants such as particles, toxic vapors, and/or gases. They are appropriate for use in environments of low-level contamination and in environments where there is sufficient oxygen. – Tight fitting facepieces or coverings produce a protective seal around the face of the user. – Air is purified when it passes through a filtering media at the inlet cover of the facepiece – Tight fitting facepieces are available in two basic types: ▪ Half Mask ▪ Full Face Types of Respirators Air PurifyingRespirators (APR) – NIOSH-approved particulate filtering facepiece respirators are often called N95 or dust masks. This type of air-purifying respirator protects by filtering particles out of the air the user is breathing. – Various types include: • • • • • • • • N95 - Filters at least 95% of airborne particles. Not resistant to oil. Surgical N95 - A NIOSH-approved N95 respirator that has also been cleared by the Food and Drug Administration (FDA) as a surgical mask. N99 - Filters at least 99% of airborne particles. Not resistant to oil. N100 - Filters at least 99.97% of airborne particles. Not resistant to oil. R95 - Filters at least 95% of airborne particles. Somewhat resistant to oil. P95 - Filters at least 95% of airborne particles. Strongly resistant to oil. P99 - Filters at least 99% of airborne particles. Strongly resistant to oil. P100 - Filters at least 99.97% of airborne particles. Strongly resistant to oil. Remember: N- Not resistant to Oil R – Resistant to Oil P – Oil Proof Types of Respirators Air PurifyingRespirators (APR) – Powered Air Purifying (PAPR) • Available in half mask, full facepiece, loose fitting facepiece helmets or hoods) Types of Respirators Atmosphere Supplying – Supplied air • Provide clean air from either a portable cylinder or from a remote source and are used in environments too hazardous for air-purifying respirators. • Available in half mask, full facepiece, loose fitting facepiece helmets or hoods) Types of Respirators Atmosphere Supplying – Self Contained Breathing Apparatus (SBCA) Half Mask Respirator Parts Half Mask Respirators – Uses & Limitations Reusable Half Mask & Vapor Respirators – Air Purifying devices that cover your nose, mouth, & chin. May be used for protection against gases, vapors, or particulates. – Gas & Vapor Respirators have replaceable cartridges that capture gases and vapors from the air. – Half mask respirators will not work if they are not properly fitted to the wearer’s face. The wear should perform a positive and negative fit test before entering a hazardous area. Full Face Respirator Parts Full Face Respirators – Uses & Limitations Full Face Respirators – Air Purifying devices similar to the Half Mask that cover your nose, mouth, & chin, but with the addition of a facepiece to protect your eyes and face. – Cartridges contain chemicals to absorb gases and vapors. – Allows for the reduction of concentration levels of gases, vapors, or particle hazards. Like the Half Face Respirator, it does not protect against oxygen deficiency, temperature extremes, or hazards not listed on the cartridge. Air-line and Self-Contained Respirators – Uses & Limitations Air-line and Self-Contained – Provide additional head, eye, and face protection. – Air-line respirators will supply you with clean air from a hose. – SCBA’s allow more mobility. – Both protect from oxygen deficiency, temperature extremes, and high concentrations of dusts, fumes, mists, gases, and vapors. Inspection of Respirators • Examine the facepiece for excessive dirt, cracks, tears, holes, or distortion. • Check for cracked or broken air-purifying element holder(s), badly worn threads, or missing gaskets. • Examine the head straps/harness for breaks, loss of elasticity, broken or malfunctioning buckles and attachments. • Remove the exhalation valve cover and examine for foreign material (detergent, residue, dust particles, hair), cracks, tears, or distortion. Look for improper insertion of the valve body and cracks, breaks, or chips in the valve body. Check for missing or defective valve covers and improper installation of the valve. Inspection of Respirators • Examine air-purifying elements for the correct cartridge, canister, or filter. Look for incorrect installation, loose connections, missing or worn gaskets, or cross-threading in holder. Verify the shelf-life date on cartridges/canister and look for cracks or dents on outside case. Inspect for evidence of prior use of sorbent cartridge indicated by absence of sealing material, tape, or foil over inlet. Maintenance, Cleaning, and Storage of Respirators • Routinely inspect respirator before and after each use, after cleaning, and after any maintenance. • Only use manufacturer recommended replacement parts when needed. Do not combine different manufacturer parts. • Employees are responsible for their own day to day cleaning and maintenance of their respirators. • Respirators must be cleanied and sanitized after each use. • Remove canisters and discard after use. • Immerse respirator in a warm solution of a germicidal detergent and water. Gently wash all areas of the respirator. Non-alcohol wipes may also be purchased and used for cleaning. • Rinse, Sanitize, and air dry respirator. • Store in a plastic bag on a shelf or in a cabinet. Do NOT store by hanging respirators from head straps/harness. Do and Don’t • Don’t wear a respirator unless you are approved and fitted to wear one. • Do ensure you are fit tested annually. – Also, if weight fluctuates or facial/dental alterations occur, a fit test should be done again to ensure the respirator remains effective. • Do inspect the respirator before wearing it. • Do wear the size/model that you were fit tested for. • Do have a clean shaven face to ensure a good seal. – Facial hair that lies along the sealing area of the respirator such as beards, sideburns, or even a few days of growth of stubble, shall not be permitted because it will prevent a good seal and may cause leakage of the respirator and cause contaminants to enter your breathing zone. • Do complete a Negative and Positive Pressure Test each time you don a respirator. • Do maintain appropriate sanitation and storage of your respirator. N95, P99, P100 Particulate Respirators – Donning Particualte Respirators: – Slightly bend the nosepiece to form a gentle curve. – Find the two headbands and separate using your index finger and thumb. – Cup the respirator under your chin. – Pull the upper headbands up over your head and position at the corner of your head. – Pull the lower headband and position at the base of your neck – Conform the nosepiece across the bridge of your nose by firmly pressing down with your fingers. – Continue to adjust the respirator and secure the edges until you acheive a good fit. – Adjust the respirator as needed during work to ensure a good fit. N95, P999, P100 Particulate Respirators – Seal Check Checking your Seal: – Place both hands over the respirator, take a quick breath in to check whether the respirator seals tightly to your face. – Place both hands completely over the the respirator and exhale. If you feel leakage, there is not a proper seal. – If air leaks around the nose, adjust the nosepiece. If air leaks at the mask edge, adjust the straps along the sides of your head until a proper seal is achieved. – If you cannot achieve a proper seal due to air leakage, try a different size or model. N95 Particulate Respirators – Doffing Removing the Respirator: – Do not touch the front of the respirator; it may be contaminated. – Remove by pulling the bottom strap over the back of the head, followed by the top strap. – Discard the used respirator. – Wash your hands. NIOSH-Certified Respirators Some disposable masks are not ‘respirators’ at all, since they are not NIOSH (National Institute for Occupational Safety and Health) certified. – Do not use these for tasks where a real respirator is needed, it will not provide the level of protection needed. Inspection and Assembly for Half or Full Face Respirator– Example using North ½ Mask Respirator Donning a Half or Full Face Respirator– Example using North ½ Mask Respirator User Seal Checks for a Half or Full Face Respirator– Example using North ½ Mask Respirator Respirator Cartridges/Filters • Filters are an essential component used with negative and positive pressure air purifying respirators to remove solid or liquid aerosols (e.g. dusts, fumes, smokes, mists) from the inspired air. • The requirement to replace a filter is not the same as chemical cartridges. Filters should be replaced when breathing becomes labored or as needed for sanitary reasons. • Mechanical filter elements provide protection against particulate matter such as dusts, mists, fibers, mold, bacteria, and metal fumes. This type of element "filters" particulate matter by physically trapping it in the fibrous filter material. Respirator Cartridges/Filters • Filters have different classifications of filter efficiency based on the NIOSH testing procedures for protection against oil mist. • P100 filter designation is the primary type of filter used for protection against dusts, mists, fumes, smokes (any particulates). It has been tested for a 99.97% filter efficiency when tested against 0.3 um docytl phthalate (DOP- "oil mist") particles. • P100 filters are color coded purple/magenta. Respirator Cartridges/Filters • High efficiency particulate air (HEPA) filter means a filter that is at least 99.97% efficient in removing particles of 0.3 micrometers in diameter. The equivalent NIOSH 42 CFR 84 particulate filters are the N100, R100, and P100 filters. Respirator Cartridges/Filters A Cartridge is a container with a filter, sorbent, or catalyst, or combination of these items, which removes specific contaminants from the air passed through the container. They differ from aerosol filters in that they use sorbents, generally carbon to remove harmful gasses and vapors. • Colors are used for easy identification of respirator cartridges and filters. The color is based on the type of air contaminant(s) for which the user will require protection. Organic Vapors-Black Acid Gases–White Organic Vapors/Acid Gases-Yellow Ammonia/Methylamine-Green Formaldehyde/Organic Vapor-Olive/Black Multi-Gas Vapor- Olive Mercury Vapor/Chlorine Gas- Orange P100 & HEPA filters-Purple/Magenta Respirator Cartridges/Filters • Chemical cartridges are filled with a specially treated activated carbon with a very high adsorption capacity. Gases and vapors passing through chemical cartridges are attracted and held to the surface of the carbon. In the case of acid and alkaline gases, a chemical reaction and/or absorption occurs. The adsorption capacity is limited. • It is important to implement a chemical cartridge change out schedule. The change schedule described in the plan for canister and cartridges must be based on objective information or data (e.g. industrial hygiene air monitoring data) that will ensure that canisters or cartridges are changed before their end of service life. The service life of the chemical cartridges will vary. Respirator Cartridges/Filters • Changing the cartridges on a regular basis will prevent "breakthrough" and will prevent the wearer from being exposed to air contaminants as a result of overuse of a saturated chemical cartridge. When using a respirator for protection for gases and vapors, if you detect a chemical taste, smell, or irritation, you should exit to a clean area and replace the cartridges and inspect the respirator immediately. Protection Factors • The amount of protection a respirator can provide is determined by an Assigned Protection Factor (APF). APF’s are assigned by OSHA and are legally enforable. • The higher the concentration of airborne contaminates, the greater the need for a high APF. • APF’s are numerical ratings that relay the anticipated protective ability against a given contaminate. The higher the APR, the greater protection provided by the respirator. • A protection factor of 50 means that you can be exposed to an atmosphere concentration 50 times higher than the PEL (permissible exposure limit). Protection Factor = Concentration of Particles Outside Mask Concentration of Particles Inside Mask Levels of Protection Mask types Air purification No maintenance 10 x TLV Low maintenance 10 x TLV Air measurements Continuous flow Half mask or full mask 10000 x TLV Maintenance required 10 x TLV Full Mask Self-contained 100 x TLV Forced supplied air 1000 x TLV 10,000 x TLV How to Determine the Protection Level? • The Occupational Exposure Limit x APF = maximum airborne contaminate concentration in which the respirator can be used. • Example: If the established occupational exposure limit for chemical A is 10ppm (parts per million), a full face respirator with an APF of 50 can safely be used in airborne concentrations of up to 500ppm. (10ppm X 50 APF = 500) Fit Testing • Employees at Clemson University are required to receive a quantitative fit test with the respirator that they will be using. The fit-testing will occur prior to initial use of the respirator, or whenever a different respirator facepiece (size, style, model, or make) is used, and at least annually thereafter. • An additional fit-test is conducted whenever the employee, supervisor, or Research Safety makes visual observations of changes in the employee's physical condition that could affect respirator fit. • Such conditions include, but are not limited to, facial scarring, dental changes, cosmetic surgery, or any obvious change in body weight. The employee may select a different respirator if he/she does not think the respirator fit is acceptable, even after passing the test. Voluntary Use of Respirators Respirators are an effective method of protection against designated hazards when properly selected and worn. Respirator use is encouraged, even when exposures are below the exposure limit, to provide an additional level of comfort and protection for workers. However, if a respirator is used improperly or not kept clean, the respirator itself can become a hazard to the worker. Sometimes, workers may wear respirators to avoid exposures to hazards, even if the amount of hazardous substance does not exceed the limits set by OSHA standards. If your employer provides respirators for your voluntary use, or if you provide your own respirator, you need to take certain precautions to be sure that the respirator itself does not present a hazard. You should do the following: 1. Read and heed all instructions provided by the manufacturer on use, maintenance, cleaning and care, and warnings regarding the respirators limitations. 2. Choose respirators certified for use to protect against the contaminant of concern. NIOSH, the National Institute for Occupational Safety and Health of the U.S. Department of Health and Human Services, certifies respirators. A label or statement of certification should appear on the respirator or respirator packaging. It will tell you what the respirator is designed for and how much it will protect you. 3. Do not wear your respirator into atmospheres containing contaminants for which your respirator is not designed to protect against. For example, a respirator designed to filter dust particles will not protect you against gases, vapors, or very small solid particles of fumes or smoke. 4. Keep track of your respirator so that you do not mistakenly use someone else's respirator. Contacts If you have any questions regarding the content of this training or general questions regarding respirators, please feel free to contact the Research Safety Industrial Hygiene team. Anne Kogut | Industrial Hygiene Manager (352)455-2354 akogut@Clemson.edu Naomi Kelly | Chemical Hygiene Officer (864)656-7554 nkelly@Clemson.edu Candis Duncan | Industrial Hygiene Specialist (864)656-0989 csdunca@Clemson.edu Office of Research Safety 114 Long Hall Clemson, SC 29634-5737 www.clemson.edu/research/safety