RESPIRATOR REFERENCES - the Mining Quiz List

advertisement

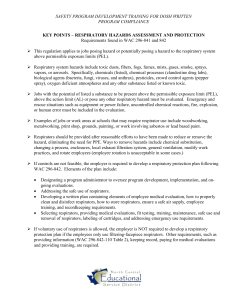

RESPIRATOR REFERENCES • 29 CFR 1910.134 • ANSI Z88.2-1992 29 CFR 1910 RESPIRATORY PROTECTION • In controlling those occupational diseases caused by breathing contaminated air, the primary objective shall be to prevent atmospheric contamination. RESPIRATORY PROTECTION • HAZARDS: - DUSTS - FOGS - FUMES - MISTS - GASES - SMOKE - SPRAYS - VAPORS Respiratory Protection SOP’s, Signs Enclosure’s, confinement, general/ local ventilation, substitution Respirators and Clothing Respiratory Protection • 29 CFR 1910.134 states that when effective engineering controls are not feasible (or while they are being instituted or evaluated), appropriate respirators shall be used Many occupational activities expose personnel to air contaminants which can be dangerous, if inhaled. The best means of protecting personnel from exposure to potentially hazardous materials is to eliminate the air contaminant at its source. When elimination of the air contaminant is not possible, the preferred protection method is engineering controls. Activity work center personnel shall use respirators where neither elimination of the air contaminant nor use of engineering controls is wholly effective. Respiratory Protection • The employer shall include in the written program the following provisions of the standard, as applicable: – Standard operating procedures governing the procedures for selecting respirators for use in the workplace – Medical evaluations of employees required to use respirators – Fit testing procedures for tight-fitting respirators – Procedures for proper use of respirators in routine and reasonably foreseeable emergency situations – Procedures and schedules for cleaning, disinfecting, storing, inspecting, repairing, discarding, and otherwise maintaining respirators Respiratory Protection – Procedures to ensure adequate air quality, quantity and flow of breathing air for atmosphere-supplying respirators – Training of employees in the respiratory hazards to which they are potentially exposed during routine and emergency situations – Training of employees in the proper use of respirators, including putting on and removing them, any limitations on their use, and their maintenance – Procedures for regularly evaluating the effectiveness of the program MCO 5100.8F Para 13008 Whenever respiratory protection is required, activities shall establish and maintain a respiratory protection program per this chapter and 29 CFR 1910.134. The Commanding Officer or Officer-In-Charge shall appoint a respiratory protection program manager (RPPM) who shall implement program requirements of Section 13008. Types of Respirators: • Air-Purifying Respirators –Gas and Vapor-Removing Respirators –Particulate Respirators •Powered Air-Purifying Respirator •Supplied Air Respirators –Air-line Respirators (Types C and CE) •Self-Contained Breathing Apparatus –Closed Circuit –Open Circuit –Demand Pressure Flow –Demand Continuous Flow –Escape-Only SCBAs FOOT PROTECTION CON’T • IF WORKING AROUND ELECTRICAL WIRES, BOOTS/SHOES MUST BE METAL FREE AND NONCONDUCTIVE • STATIC FREE ENVIRONMENTS REQUIRE CONDUCTIVE SHOES • RUBBER OR SYNTHETIC FOOTWEAR MAY BE REQUIRED AROUND CHEMICALS • AVOID LEATHER SHOES/BOOTS AROUND CORROSIVES • FOOT GUARDS AND HEEL AND ANKLE SHIELDS MAY BE REQUIRED FOR PARTICULAR WORK Respiratory Protection • For protection against gases and vapors: – An atmosphere-supplying respirator, or – An air-purifying respirator, provided that the respirator is equipped with an end-of-service-life indicator (ESLI) certified by NIOSH for the contaminant or • If there is no ESLI appropriate for conditions, the employer implements a change schedule for canisters and cartridges based on objective information or data that will ensure that canisters and cartridges are changed before the end of their service life. Respiratory Protection • For protection against particulates, the employer shall provide: – An atmosphere-supplying respirator or – An air-purifying respirator equipped with a filter certified by NIOSH under 30 CFR part 11 as a HEPA filter or an air-purifying respirator equipped with a filter certified for particulates by NIOSH under 42 CFR part 84 Respiratory Protection • Particulate Filtering (42 CFR 84) – Filter Series N • Non-specific service time – Filter Series R • One work shift (8 hours) service time – Filter Series P • Non-specific service time for use against both oil and non-oil particulate aerosol(s) Respiratory Protection • Respirators for IDLH atmospheres. – A full facepiece pressure demand SCBA certified by NIOSH for a minimum service life of thirty minutes – A combination full facepiece pressure demand supplied-air respirator (SAR) with auxiliary selfcontained air supply • Respirators provided only for escape from IDLH atmospheres shall be NIOSH-certified for escape from the atmosphere in which they will be used • All oxygen-deficient atmospheres shall be considered IDLH Respiratory Protection Respiratory Protection • Medical evaluation – Employer’s must provide a medical evaluation to determine an employee's ability to use a specific respirator, before the employee is fit tested or required to use that respirator in the workplace – The medical evaluation shall obtain the information requested by the questionnaire in Sections 1 and 2, Part A of Appendix C of 29 CFR 1910.134 Respiratory Protection • Fit Testing Paragraph F of the standard, requires that, before an employee may be required to use any respirator with a negative or positive pressure tight-fitting facepiece, the employee must be fit tested initially and annually, thereafter – Qualitative fit test – Quantitative fit test MAINTENANCE • INSPECTION OF EQUIPMENT BEFORE AND AFTER USE • REPAIR DAMAGE OR REPLACE IT • CLEAN AND SANITIZE EQUIPMENT • PROPER STORAGE AND HANDLING OF ALL PPE • TRAINING MISCELLANEOUS PPE • • • • • • • LIFE PRESERVERS (PFD) WRIST RESTS SUN, WIND AND DUST GOGGLES CRANIALS SEAT BELTS SAFETY HARNESS RUBBER APRON CONCLUSION • CONDUCT A HAZARD ASSESSMENT • • • • • • • SELECT THE CORRECT PPE CORRECTLY USED MEDICAL SURVEILLANCE MAINTENANCE OF PPE TRAINING ENFORCEMENT PPE IS DESIGNATED FOR YOUR SAFETY AND WELL BEING