open presentation

advertisement

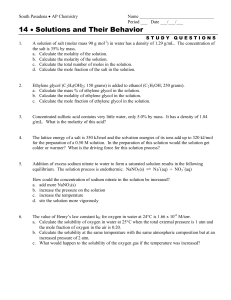

Greenhouse Gas Mitigation Benefits of Expanding the U.S. Renewable Fuel Standard to Promote Biomass Use in Chemical Feedstocks I. Daniel Posen*,1,2 W. Michael Griffin1, H. Scott Matthews,1,2 and Inês Azevedo1 1Department of Engineering and Public Policy 2Department of Civil and Environmental Engineering Carnegie Mellon University 1 I. Background 2 Context: U.S. Biofuel Incentives • Renewable Fuel Standard (RFS2) – Established by Energy Independence and Security Act of 2007 (EISA) – Sets minimum biofuel targets – How are we doing? 138 60 Gasoline Diesel Production in 2022: Fuel Volume (Billion Gallons) 40 30 20 16 billion gal Cellulosic Biofuel Bio-diesel Advanced Biofuel 5 billion gal Renewable Biofuel 15 billion gal 10 0 2008 2012 2016 2020 3 Challenges • Some Problems for the Renewable Fuel Standard – Excess capacity faces demand-side limitations – Ethanol is an imperfect substitute for gasoline – Narrow scope • Concurrent Problem: – Chemical industry a major contributor to greenhouse gas emissions and consumer of non-renewable energy (~5% in the U.S. ) • Possible Solution / Policy Recommendation: – Expand RFS2 to include credits for chemical use of bio-ethanol 4 Chemical Use for Ethanol • Ethylene case study – Easily made from ethanol – Critical building block for chemical industry – Wide range of uses • Biggest use: Polyethylene 5 Key Research Questions • Can bio-based low density polyethylene (bio-LDPE) meet RFS2 greenhouse gas (GHG) targets? • Does bio-LDPE achieve similar GHG benefits to bio-ethanol fuel? 6 II. Methods 7 Overview • Life-Cycle Assessment (LCA) used to quantify greenhouse gas emissions from various fuel and chemical pathways. U.S. Corn U.S. Switchgrass Brazilian Sugarcane Ethanol (1.74 kg) Ethanol Fuel Gasoline (46.9 MJ) Crude Oil • • Bio-LDPE Compare (1 kg) Compare Compare (46.9 MJ) Fossil LDPE (1 kg) Natural Gas Ethane Emphasis on quantifying uncertainty with Monte Carlo simulation. Draws primarily on literature sources and Government Data 8 Model Overview: Fossil-LDPE (Natural Gas) PRODUCTION PROCESS PRODUCTS Pre-production Lease Condensate Dry Natural Gas Extraction Wet Natural Gas Dry Natural Gas Propane Butanes Pentanes Plus Processing Ethane Steam Cracking Hydrogen Propylene Butadiene Aromatics Ethylene Polymerization LDPE (U.S.) (1 kg) 9 Model Overview: Bio-based Pathways Switchgrass Corn Sugarcane Switchgrass Cultivation Corn Cultivation Switchgrass Cultivation Feedstock Transportation Feedstock Transportation Feedstock Transportation Ethanol Production Ethanol Production Ethanol Production Ethanol (U.S.) (1.74 kg) + Electricity (U.S.) Ethanol (U.S.) (1.74 kg) Transport to Ethylene plant Fuel Distribution Dehydration to Ethylene Combustion Polymerization Ethanol (Brazil) (1.74 kg) + Electricity (Brazil) Ethanol (U.S.) (1.74 kg) +DDGS (U.S.) Ethanol (Brazil) (1.74 kg) Transport to U.S. Transport to Ethylene plant Dehydration to Ethylene Polymerization Energy (46.9 MJ) LDPE (U.S.) (1 kg) Transport to U.S. 10 III. Results 11 Simulated Emissions from Production of Low Density Polyethylene (LDPE) 1.6 1.4 Probability Density 1.2 Corn LDPE Fossil LDPE 1.0 Sugarcane LDPE 0.8 Switchgrass LDPE 0.6 0.4 0.2 0.0 -6 -4 -2 0 2 4 6 8 Life-cycle GHG Emissions (kg CO2e / kg LDPE) 12 Simulated Emissions from Production of Ethanol and Gasoline 1.6 1.4 Probability Density 1.2 1.0 0.8 Switchgrass Ethanol 0.6 0.4 0.2 0.0 -6 -4 -2 0 2 4 6 8 Life-cycle GHG Emissions (kg CO2e / 46.9 MJ) 13 Net Emissions From Alternate Pathways (kg CO2e/kg LDPE)(kg CO2e/46.9 MJ) Bio-product has lower GHG emissions than fossil counterpart Bio-product has higher GHG emissions than fossil counterpart Bio-LDPE Fuel Ethanol (gasoline replacement) Switchgrass Sugarcane Corn • Both fuel and feedstock use of switchgrass and sugarcane have the potential to reduce (even capture) greenhouse gas emissions. • Choice of feedstock is more important than how it is used 14 Can These Pathways Meet RFS2 Targets? Advanced biofuel target Cellulosic biofuel target Probability that Emission Reduction Exceeds Policy Target Renewable biofuel target • Neither corn product can meet RFS2 targets • Both sugarcane products can meet RFS2 targets Bio-LDPE Fuel Ethanol (gasoline replacement) • Both Switchgrass products can meet RFS2 targets Figure style inspired by Mullins et al. (2011) 15 Summary • Can the considered pathways meet RFS2 targets? – Yes: U.S. Switchgrass and Brazilian Sugarcane (fuel or LDPE) – No: for U.S. Corn Starch (fuel or LDPE) • Does bio-LDPE achieve the same GHG benefits as bio-ethanol fuel (any feedstock)? – Yes: for Brazilian Production (>95% confidence) – No: for U.S. Production (~80% confidence) 16 Conclusions • RFS2 credits for bio-ethylene products provides flexibility to obligated parties with no impact on end user • Recommendation depends on goal of policy – – – – Energy Security Rural Development Market Development Greenhouse Gas Mitigation • Recommendations (for greenhouse gas focus) : – Incentives for corn ethanol production should be discontinued – RFS2 credits should apply to imported Brazilian bio-LDPE – RFS2 credits should be applied to U.S. Bio-LDPE only in a demandconstrained biofuel environment 17 Acknowledgements • • • • • • • • • Steinbrenner Institute Colcom Foundation Mike Griffin Inês Azevedo Scott Matthews Kim Mullins Aranya Venkatesh Fan Tong Stefan Schweitzke This work is supported by a Steinbrenner Institute U.S. Environmental Sustainability Ph.D. Fellowship. The fellowship program is supported by a grant from the Colcom Foundation, and by the Steinbrenner Institute for Environmental Education and Research at Carnegie Mellon University. 18 I. Daniel Posen Advisors: Mike Griffin, Scott Matthews, Inês Azevedo Department of Engineering and Public Policy & Department of Civil and Environmental Engineering Carnegie Mellon University Email Address: idp@andrew.cmu.edu Image: Great Lakes Bioenergy Research Center 19 III. APPENDIX 20 Scope of Ethanol use for Ethylene • Replacement of all current U.S. ethylene production: – 14 billion gallons of ethanol – Savings up to 110 MT CO2e for switchgrass mean reductions (~1-2% of U.S. GHG emissions) • Current US consumption of ethanol (2013): 14 billion gallons • EISA 2022 Renewable fuel target: 36 billion gallons • Ethylene replacement can double current ethanol production and meet 60% of the remaining target 21 Projected Ethylene GHG Emissions (in Function of Feedstock Choice) 350 GHG Emissions (Mt CO2e) 300 250 200 Bulk Chemicals 150 Full transition to switchgrass ethylene by 2040 would Ethane mitigate: Ethylene 100 Corn Ethylene 50 • >100% of emissions from ethylene productionSugarcane Ethylene • • 0 Switchgrass Ethylene -50 Switchgrass Ethylene Net ~50% of direct emissions from bulk chemicals production -100 -150 A population 2010 2015 increase of 102030 million 2020 2025 2035people 2040 (~17% of the projected population Year increase over that time). 22 V. Rough Cost Analysis 23 Bio-ethylene is (currently) far less competitive than bio-ethanol Table 1. Implicit carbon price for bio-ethanol and bio-ethylene (90% confidence interval, $/ton CO2e) Bio-ethanol Bio-ethylene Corn N/A N/A Sugarcane (-250) – 0 200-450 Switchgrass 0-100 300-700 24 Displacement of Gasoline vs Fossil LDPE (Fossil LDPE – Bio LDPE) – (Gasoline – Bio ethanol) Bio-ethanol achieves greater GHG savings than bio-LDPE Bio-LDPE achieves greater GHG savings than bio-ethanol fuel 0.8 0.6 0.4 U.S. Production 0.2 Brazilian Production 2.0 1.5 1.0 0.5 0.0 -0.5 -1.0 -1.5 0.0 -2.0 Probability that emissions difference exceeds given level 1.0 Excess emission reduction from bio-LDPE bio-ethanol fuel (kg CO2e/kg LDPE)(kg CO2e/46.9 MJ) 25 Displacement of Gasoline vs Fossil LDPE Bio-ethanol achieves greater GHG savings than bio-LDPE Bio-LDPE achieves greater GHG savings than bio-ethanol fuel Probability that policy change meets target 1.0 0.8 0.6 0.4 U.S. Production 0.2 Brazilian Production 40% 30% 20% 10% 0% -10% -20% -30% -40% • For U.S. Production: biomass fuel use has greater GHG benefits than0.0chemical feedstock substitution (~80% confidence) • For Brazilian Production: chemical useto be ofmet biomass has Additional GHG emissions reduction target by bio-LDPE overgreater bio-ethanol fuel (% of gasoline emissions) GHG benefits than fuel use (>95% confidence) 26 Model Overview Fossil Fuel Pathways Biomass Pathways (Brazil) Crude Oil Natural Gas Corn Switchgrass Sugarcane Gasoline (life-cycle) Pre-production Corn Cultivation Switchgrass Cultivation Switchgrass Cultivation Feedstock Transportation Feedstock Transportation Feedstock Transportation Ethanol Production Ethanol Production Ethanol Production Extraction Wet Natural Gas Lease Condensate; Dry Natural Gas DDGS Processing Ethane (~1.25kg) Steam Cracking Ethylene (1.0lkg) Dry Natural Gas; Propane; Butanes; Pentanes Plus; Electricity Hydrogen Propylene Butadiene Aromatics Ethanol (1.74kg) Ethanol (1.74kg) Transport to U.S. Transport to Ethylene plant Dehydration to Ethylene Polymerization Electricity Fuel Distribution Combustion Transport to Ethylene plant Dehydration to Ethylene Polymerization Transport to U.S. Energy (46.9 MJ) LDPE (1kg) Energy (46.9 MJ) LDPE (1kg) 27 IV. Importance and Sensitivity 28 Fossil Ethylene Emissions Dominated by Steam Cracking Pre-Production Production Processing Steam Cracking Polymerization Mean (kg CO2e/kg LDPE) 0.04 0.26 0.12 0.80 0.74 Standard Deviation 0.01 0.08 0.17 0.27 0.08 Ethylene Subtotal LDPE Total 1.23 2.0 0.35 0.37 Life-cycle Stage 0.26 0.32 1.40 0.34 0.11 Lower 90% CI 0.03 0.17 0.02 0.36 0.64 Upper 90% CI 0.06 0.37 0.33 1.26 0.87 0.28 0.19 0.72 1.4 1.77 2.6 Coefficient of Variation 29 Corn Emissions are evenly distributed Corn LDPE LUC Corn farming Ethanol production Co-product credit Transportation Ethanol dehydration Polymerization EOL (growth credit) Mean (kg CO2e/kg LDPE) 1.3 2.0 2.0 -0.61 0.36 0.34 0.71 -3.1 Standard Deviation 0.22 0.46 0.20 0.04 0.03 0.08 0.08 - Coefficient of Variation 0.17 0.23 0.10 -0.07 0.09 0.24 0.11 - LDPE Total 2.9 0.56 0.20 Life-cycle Stage Lower 90% Upper 90% CI CI 0.91 1.6 1.4 2.9 1.6 2.3 -0.68 -0.54 0.32 0.41 0.23 0.49 0.62 0.85 2.0 3.9 30 Electricity Credits are Critical for Switchgrass Switchgrass LDPE Life-cycle Stage LUC Switchgrass farming Ethanol production & electricity credit Transportation Ethanol dehydration Polymerization EOL (growth credit) LDPE Total Mean (kg CO2e/kg LDPE) 0.6 0.56 Standard Deviation 0.14 0.13 Coefficient of Variation 0.25 0.23 Lower 90% CI 0.34 0.39 Upper 90% CI 0.8 0.82 -2.4 0.31 0.34 0.71 -3.1 1.20 0.01 0.08 0.08 - -0.50 0.03 0.24 0.11 - -4.4 0.30 0.23 0.62 - -0.51 0.33 0.49 0.85 - -3.1 1.2 -0.38 -5.1 -1.2 31 Sugarcane Emissions are Dominated by Farming Sugarcane LDPE Life-cycle Stage LUC Sugarcane farming Ethanol production & electricity credit Transportation Ethanol dehydration Polymerization EOL (growth credit) LDPE Total Mean (kg CO2e/kg LDPE) 0.2 0.82 Standard Deviation 0.17 0.19 Coefficient of Variation 1.01 0.23 Lower 90% CI -0.1 0.52 Upper 90% CI 0.5 1.1 -0.041 0.3 0.2 0.2 -3.1 0.042 0.02 0.05 0.05 - -1.0 0.06 0.30 0.32 - -0.12 0.3 0.1 0.1 - 0.00 0.4 0.2 0.3 - -1.4 0.26 -0.18 -1.8 -1.0 32 Surplus Electricity Sale is Essential for meeting Cellulosic Targets Probability that emission reduction Exceeds policy target Renewable biofuel target Advanced biofuel target Cellulosic biofuel target Switchgrass Chemical use (LDPE) Sugarcane Fuel use (gasoline replacement) With Surplus Without Surplus Electricity Sale Corn Reduction target (% below LC gasoline) 33 Corn Sensitivity to Land-Use Change Emissions Base Case: distribution from US EPA (2010) 2.5th Percentile 1.0 97.5th Percentile Mode 0.9 Probability of meeting target 0.8 Break-even 0.7 Chemical use (LDPE) 0.6 0.5 Fuel use (gasoline replacement) 0.4 0.3 0.2 20% reduction target 0.1 0.0 0 5 10 15 Tipper 2009d(26.6) Dunn 2013d Tyner 2010 (26.6) a: 2.5th percentile b: median and above c: “marginal” scenario d: “mean” scenario 20 25 2010a 30 35 40 Plevin Hertel 2010 (26.6) Al Riffai 2010) c Tipper 2009 45 Searchinger 2008 Plevin 2010b LUC Emissions (g CO2e / MJ corn ethanol) 50 Switchgrass Sensitivity to Land-Use Change Emissions Base Case: distribution from US EPA (2010) 2.5th Percentile Mode 97.5th Percentile 1.0 0.9 Probability of meeting target 0.8 0.7 0.6 Chemical use (LDPE) 0.5 0.4 Fuel use (gasoline replacement) 0.3 0.2 Break-even 60% reduction target 0.1 0.0 0 10 Dunn 2013 (-1.5) 20 30 40 50 60 70 80 90 100 110 120 Taheripouri 2013 (1.3) LUC Emissions (g CO2e / MJ Switchgrass ethanol) 130 140 150 Sugarcane Sensitivity to Land-Use Change Emissions Base Case: distribution from US EPA (2010) 2.5th Percentile Mode 97.5th Percentile 1.0 0.9 Probability of meeting target 0.8 0.7 0.6 0.5 0.4 0.3 50% reduction target Break-even 0.2 0.1 0.0 -10 0 10 20 Tipper c 2010 Bauen 2010 Lywood (min) (7.82-27.38) 2008 30 40 50 60 70 80 Tipper 2010 (max) LUC Emissions (g CO2e / MJ Sugarcane ethanol) 90 100 V. Rough Cost Analysis 37 Bio-ethylene is (currently) far less competitive than bio-ethanol Table 1. Implicit carbon price for bio-ethanol and bio-ethylene (90% confidence interval, $/ton CO2e) Bio-ethanol Bio-ethylene Corn N/A N/A Sugarcane (-250) – 0 200-450 Switchgrass 0-100 300-700 38 VII. The Bigger Picture 39 Next Questions We already know bio-LDPE can offer a near-perfect GHG mitigation strategy, but: • What is the scope for emissions reduction from feedstock substitution? • How do chemical needs influence the picture of long-term resource limits? • What is the best use for biomass from a larger set of options? • What is the best way to green the chemical industry? 40 Bulk Chemicals Projected Growth Value of Shipments 400 300 Energy Consumption 200 100 0 2010 2015 2020 2025 2030 2035 2040 CO2 Emissions (Mt) Greenhouse Gas Emissions 350 300 250 200 150 100 50 0 2010 2015 2020 2025 2030 2035 2040 Energy Consumption (Quadrillion BTU) Value of Shipments (billion 2005 dollars) 500 8 7 6 5 4 3 2 1 0 2010 2015 2020 2025 2030 2035 2040 EIA (2014). Annual Energy Outlook 41 Projected Ethylene GHG Emissions (in Function of Feedstock Choice) 350 GHG Emissions (Mt CO2e) 300 250 200 Bulk Chemicals 150 Full transition to switchgrass ethylene by 2040 would Ethane mitigate: Ethylene 100 Corn Ethylene 50 • >100% of emissions from ethylene productionSugarcane Ethylene • • 0 Switchgrass Ethylene -50 Switchgrass Ethylene Net ~50% of direct emissions from bulk chemicals production -100 -150 A population 2010 2015 increase of 102030 million 2020 2025 2035people 2040 (~17% of the projected population Year increase over that time). 42 Projected Light Duty Vehicle (LDV) Fuel Use 140 Billion Gallons of Fuel 120 100 80 Motor Gasoline 60 Ethanol for LDV 40 20 0 2010 2015 2020 2025 Year 2030 2035 2040 EIA (2014). Annual Energy Outlook 43 Projected Light Duty Vehicle GHG Emissions (in Function of Fuel Choice) GHG Emissions (Mt CO2e) 2000 1500 Gasoline 1000 Corn Ethanol Full transition from gasoline to switchgrass ethanol Sugarcane by 2040Ethanol would 500 mitigate: 0 Switchgrass Ethanol • 70-120% of emissions from LDV gasoline use • -500 A population increase 30-70 million 2010 2015 2020 of 2025 2030 2035people 2040 (~50-120% of the projected population increase over that time). Year Switchgrass Ethanol without electricity 44 Resource Limits: Land for bio-energy “Bio-based chemicals and other biomaterials might add significantly to the growing biomass demand, yet they are not usually included in biomass potential or demand estimates.” (Dornburg 2010). • 2050 North American bio-energy potential: 38-102 EJ (Smeets 2006) • 2030 U.S. potential with strict environmental controls: 5 EJ (UCS 2012) Today 2040 Ethylene 1.2 EJ 1.8-2.0 EJ All Chemical Feedstocks 3.3 EJ 4.4-4.8 EJ LDV Gasoline/Ethanol 16 EJ 10-12 EJ Total U.S. Energy Needs 100 EJ 100-120 EJ 45 Long-term Conclusions • Biofuels and bio-based chemicals offer substantial scope for greenhouse gas mitigation • Ethylene production need not present a long-term challenge for greenhouse gas emissions – Incentives to begin the long-term transition can be implemented immediately • Chemical production alone will not be resource limited • Total U.S. food, energy and chemical needs may be resource limited – Estimates of bio-energy production potential must be updated to reflect chemical needs 46 Human Appropriation of Net Primary Production (HANPP) North America NPP: 7 GtC / yr HANPP: 1.6 GtC / yr (25%) Additional HANPP from RFS : • 0.15 GtC / yr • 2% of NPP • 10% of HANPP Additional HANPP from replacing all U.S ethylene: • 0.06 GtC / yr • 1% of NPP • 4% of HANPP World NPP: 60 GtC / yr HANPP: 15 GtC / yr (25%) Additional HANPP from replacing all world ethylene: • 0.29 GtC / yr • 0.5 % of NPP • 2% of HANPP 47 Resource Limits: Land • U.S Arable Land: 1.6 million km2 • World Arable land: 59 million km2 • Land used to replace all US ethylene: – With Corn: 130 thousand km2 (8% of US arable land) – With Switchgrass: 85 thousand km2 (5% of US arable land) • Land use to replace global ethylene: – With Corn: 670 thousand km2 (1% of arable land) – With Switchgrass: 440 thousand km2 (0.7% of arable land) 48 Resource Limits: Land for bio-energy • World bio-energy potential: 65-300 EJ (Van Vuuren 2009) • U.S. primary energy consumption in 2012: 100 EJ – Predicted growth through 2040: 0.3% per year (EIA 2013) • Ethanol used to replace all U.S. ethylene: 1.1 EJ • Ethanol used to replace global ethylene: 5.8 EJ 49 Long-term Conclusions • Ethylene production need not present a long-term challenge for greenhouse gas mitigation – Incentives to begin the long-term transition can be implemented immediately • Ethylene production alone will not be resource limited • Estimates of resource limits for bio-energy production must be updated to reflect chemical needs 50 ORIGINAL APPENDIX 51 Model Overview Fossil Fuel Pathways Biomass Pathways (Brazil) Crude Oil Natural Gas Gasoline (life-cycle) Wet Natural Gas Corn Switchgrass Sugarcane Ethanol (1.74kg) Ethanol (1.74kg) Ethane (~1.25kg) Ethylene (1.0lkg) Energy (46.9 MJ) LDPE (1kg) Energy (46.9 MJ) LDPE (1kg) Energy (46.9 MJ) LDPE (1kg) 52 Sources • Fossil LDPE model inspired by modeling from Venkatesh et al. (2011); data from multiple sources • Corn and Switchgrass based on a reconstruction of Mullins et al. (2011) with slight modification • Sugarcane pathway based on a modified reconstruction of Seabra et al. (2011) and Liptow and Tillman (2012) • Ethanol dehydration from Kochar (1981) • Polymerization as per Liptow and Tillman (2012) • Distribution for Gasoline from Venkatesh et al. (2011) 53 Scope of Ethanol use for Ethylene • Replacement of all current U.S. ethylene production: – 14 billion gallons of ethanol – Savings up to 110 MT CO2e for switchgrass mean reductions (~1-2% of U.S. GHG emissions) • Current US consumption of ethanol (2012): 13 billion gallons • EISA 2022 Renewable fuel target: 36 billion gallons • Ethylene replacement can double current ethanol production and meet 60% of the remaining target 54 Cost of Bio-Ethylene Production International Renewable Energy Agency (IRENA), Production of Bio-Ethylene: Technology Brief; 2013 55 Pre-Production Weber and Clavin (2012): • Well Pad Constructions • Well Drilling • Production of Chemicals for Hydraulic Fracturing • Water Management for Hydraulic Fracturing EPA and other sources: • Well Completions and Workovers – Conventional – Unconventional (uncontrolled) – Conventional (reduced emission) 56 Production EIA State Level Data: • Lease Fuel Consumption • Natural Gas Vented and Flared – Base Case assumes all flared EPA GHG Inventory: • Fugitive Methane 57 Processing • Facilities matched from EPA Greenhouse Gas Reporting Program and EIA Processing Capacity Database – 222 facilities matched, accounting for 80% of processing • Data treated for outliers and examined for both linear trends and Heteroskedasticity • Continuous distribution fitted to data weighted by average daily processing 58 Processing Emission Data Fitting 0.45 0.40 0.30 0.25 0.20 0.15 0.10 0.05 15 Tons CO2e / MMCf Processed 12 9 6 3 0.00 0 Probability Density 0.35 59 Ethane Steam Cracking • Energy input required: 15-25 GJ/t ethylene (multiple sources) – Simulated with uniform distribution • Distributions of products and losses simulated with triangular or uniform distributions (multiple sources) • Ethylene, Propylene, Butadiene and Aromatics treated as products for allocation • Hydrogen treated as product for system expansion – Uniform distribution for emissions from steam reforming • All other products burned for fuel • Excess fuel requirements met by dry natural gas; Life-cycle emissions from Venkatesh et al. (2011) 60 Natural Gas Pre-Production Parameters Parameter Well pad construction Value or distribution Triangular (0.05, 0.13, 0.3) Units g CO2e/MJ Source (Weber and Clavin 2012) Well Drilling Triangular (0.1, 0.2, 0.4) g CO2e/MJ (Weber and Clavin 2012) Fracking Chemicals Triangular (0.04, 0.23, 0.5) g CO2e/MJ (Weber and Clavin 2012) Fracking Water Management Triangular (0.04, 0.07, 0.1) g CO2e/MJ (Weber and Clavin 2012) Gas venting for conventional well completions Gas venting for conventional well workovers Conventional well annual workovers Operating Lifetime of Conventional well Daily production for conventional well Uncontrolled gas vented/flared for unconventional completions and workovers Unconventional Well Estimated Ultimate Recovery Flowback Captured in Reduced Emission Completions 0.71 0.05 1 5 0.15 tons CH4/completion tons CH4/workover workover/year Years MMscf/day (U.S. EPA 2010) (U.S. EPA 2010) (Venkatesh, et al. 2011) (Venkatesh, et al. 2011) (Venkatesh, et al. 2011) Normal (8900,2006067) Mcf “CH4”/completion (U.S. EPA 2012) Triangular (0.5, 2, 5.3) Bcf (Weber and Clavin 2012) 90% % (U.S. EPA 2011) Flare Efficiency Uniform (51,100) (100% for regulated scenario) 98% Number of refractures per unconventional well Bionomial (p = 0.01, n= 30) # Green Completion Percentage 51% 100% (for regulated scenario) % State by state % (U.S. EIA 2013c) By NEMS region for each state % (U.S. EPA 2013a) Percent of released gas which is flared Convention unconventional percent of growth withdrawals 2011 CO2 and CH4 content in raw natural gas % % (Jiang, et al. 2011) (Federal Register 2012) (Jiang, et al. 2011) (U.S. EPA 2012) for p (U.S. EIA 2013h) for n (U.S. EPA 2012) (Federal Register 2012) 61 Natural Gas Production, Processing and Cracking Parameter Value or distribution Units Source Production Lease Fuel Consumed Gas Vented and Flared State by state (discrete distribution) State by state (discrete distribution) Triangular (.81*best, best, 1.30*best) by (aggregated) NEMS region(s) MMcf/year MMcf/year (U.S. EIA 2013c) (data from 2011 reporting year) (U.S. EIA 2013d) (data from 2011 reporting year) Mg CH4/year (U.S. EPA 2013c) (data from 2011 reporting year) Log-logistic(1.66,2.12) tons CO2e/MMcf processed Own Analysis of (U.S. EIA 2013b, U.S. EPA 2013a) Specific Energy Required Uniform (15,25) GJ/t ethylene (EC 2003, Ren et al. 2006, Worrell et al. 2000) Ethylene Produced Propylene Produced Butadiene Produced Aromatics Produced Hydrogen Produced Methane Produced C4 Components Produced C5 and C6 Components Produced Product Losses Triangular (764, 803, 840) Triangular (14.1, 16, 29.9) Triangular (17.4, 19.9, 23) Uniform (0, 19.9) Triangular (57.9, 60, 89.7) Triangular (58.8, 61, 70.1) Triangular (0, 6, 8.1) Uniform (0, 26) Uniform (3, 20) kg/ton ethane kg/ton ethane kg/ton ethane kg/ton ethane kg/ton ethane kg/ton ethane kg/ton ethane kg/ton ethane kg/ton ethane (ACC 2004, EC 2003, Neelis et al. 2005, Ren et al. 2006, Worrell et al. 2000) kg CO2e/kg H2 Multiple sources consulted. Lower bound from (Boustead 2005) as cited in SimaPro software. Upper bound from (Spath and Mann 2001) Production CH4 Emissions Processing Processing Emissions Steam Cracking Emissions from Hydrogen Production via steam reforming (for system expansion) Uniform (7.8, 12) 62 Corn Ethanol Parameters Parameter Land-use Change Value or Distribution Units Domestic (Direct) Land Use Change Uniform (-4, 55) kg CO2e/mmBtu International (Indirect) Land Use Change Triangular (20.9, 31.8, 44.7) kg CO2e/mmBtu Lower bound from (U.S. EPA 2010b); upper bound converted from (Fargione et al. 2008) as cited in (Mullins et al. 2011) Fit to confidence interval given by (U.S. EPA 2010b) Beta (α=21.62, β=5.86, [0,14.3]) Mg dm/ha (Mullins et al. 2011) Nitrogen Application Triangular (141, 150, 160) kg N / ha (Paz et al. 1999) as cited in (Mullins et al. 2011) Crop residue applied Triangular (73, 80, 86) kg N / ha Fossil Fuel Use 968 g CO2e / bushel Corn starch content Triangular(62.6, 67.3 ,72) %w of dry matter Heat input Triangular (0.32, 0.42, 0.51) MJ heat / MJ EtOH Electricity input Triangular (0.023,0.038,0.049) MJ elec/MJ EtOH Co-product credit 15 g CO2e/MJ EtOH 454 g CO2e/bushel 1000 km 0.0203 L diesel / t-km Agricultural Operations Corn Yield Source From (Klein et al. 2006) as modeled by (Mullins et al. 2011) Calculated from (Wang 2013) Ethanol Production Transportation Feedstock transportation Trucking distance for ethanol to ethylene plant Truck fuel consumption (Kwiatkowski et al. 2006) and (Boyer and Shannon 2003) as used in (Mullins et al. 2011) (Kwiatkowski et al. 2006, McAloon et al. 2000, Perrin et al. 2009) as cited in (Mullins et al. 2011) (Plevin 2009) as cited in (Mullins et al. 2011) Calculated from (Wang 2013) Approximate distance from mid-west to gulf states (NREL 2013c) 63 Switchgrass Parameters Parameter Land-use Change Domestic (Direct) Land Use Change International (Indirect) Land Use Change Agricultural Operations Switchgrass Yield Nitrogen Application Crop Residue Applied Fossil Fuel Use Ethanol Production Glucan Content Xylan Content Mannan Content Galactan Content Arabinan Content Lignin Content Energy Input Percent of energy to electricity, heat Boiler efficiency Turbine Efficiency Transportation Feedstock Transportation Trucking distance for ethanol to ethylene plant Truck fuel consumption Value or Distribution Units Uniform (-4, 55) kg CO2e/mmBtu Triangular (7.9, 15.1, 23.7) Source Lower bound from (U.S. EPA 2010b); upper bound from (Fargione et al. 2008) Fit to confidence interval given by (U.S. kg CO2e/mmBtu EPA 2010b) Beta (α=21.62, β=5.86, [0,21.6]) Mg dm / ha (Mullins et al. 2011) Triangular (55, 74, 100) kg N/ ha Triangular (143.5, 133.5, 171.7) kg N / ha 22 g CO2e/ kg SW (McLaughlin and Walsh 1998, Schmer et al. 2008) as cited in (Mullins et al. 2011) From (Klein et al. 2006) as modeled by (Mullins et al. 2011) Calculated from (Wang 2013) Triangular (31, 34.4, 37.2) Triangular (20.6, 23.0, 26.0) Triangular (0.29, 0.32, 0.36) Triangular (0.67, 1.0, 1.2) Uniform (2.6, 3.4) Triangular (17.3, 19.2, 21.1) Uniform (0.44, 0.72) %w %w %w %w %w %w MJ / MJ EtOH 10% / 90% MJ (Aden et al. 2002, Luo et al. 2009) as cited in (Mullins et al. 2011) 15 g CO2e/ kg SW 1000 km 0.0203 L diesel / t-km Calculated from (Wang 2013) Approximate distance from mid-west to gulf states (NREL 2013c) 68% 85% (U.S. DOE 2009) as cited in (Mullins et al. 2011) 64 Sugarcane Parameters Parameter Value or Distribution Units Source Triangular (-3.7, 4.3,11) g CO2e/MJ EtOH (U.S. EPA 2010b) Normal(86.7,13.4) Normal (274,75) t cane / ha L diesel /ha (Seabra et al. 2011) (Seabra et al. 2011) Nitrogen Application Triangular (39, 777, 1515) g N/t cane (Seabra et al. 2011) Trash burning Emissions from Trash Burning Triangular (3,82,126) 113 kg CO2e/t cane g CO2e / kg straw (Seabra et al. 2011) (Wang 2013) Normal (81.1, 4.3) Exponential (10.7) L EtOH/ t cane kWh/t cane (Seabra et al. 2011) (Seabra et al. 2011) Field to ethanol mill, fuel use 10300 kcal diesel/t cane Ethanol to ethylene plant, fuel use Shipping distance, Brazil (Parangua) to U.S. (Houston) Ship fuel consumption (Ocean Freighter) 0.217 MJ / kg ethanol (Macedo et al. 2004) as cited in (Liptow and Tillman 2009) (Liptow and Tillman 2009) 10700 Km (Sea-Rates 2013) 4.93 *10-3 L residual fuel oil/t-km (NREL 2013b) Land-use Change Land-use change (total) Agricultural Operations Harvest Yield Diesel Consumption Ethanol Production Ethanol yield Surplus Electricity Transportation 65 Common Parameters Parameter Value Units Ethanol Production (parameters used for switchgrass and corn) Hydrolysis yield Fermentation yield from glucose Uniform (0.85, 0.95) Uniform (0.85, 1) % % Fermentation yield from other sugars Uniform (0.75, 0.9) % Ethanol Fuel Distribution Emissions from fuel distribution 1.2 g CO2e/MJ Calculated from (Wang 2013) Ethanol dehydration to ethylene Ethylene yield Fuel used Electricity Used 0.57 0.40 310 kg ethylene / kg ethanol Gcal/t ethylene kWh/t ethylene Calculated from (Kochar et al. 1981) (Kochar et al. 1981) (Kochar et al. 1981) 451700 150 417 t/yr kt/yr GWh/yr (Borealis 2008) as cited in (Liptow and Tillman 2009) On-site emissions 38.9 t CO2e/yr Calculated from (Borealis 2008) as cited in (Liptow and Tillman 2009) LDPE share of energy consumption 0.40 Unitless (Liptow and Tillman 2009) Polymerization Input Ethylene Output LDPE Electricity Used Source (Sheehan et al. 2003) as cited in (Mullins et al. 2011) 66 Fuels, Electricity and Agrochemicals Parameter Fuel Emissions Gasoline life-cycle emissions Diesel life-cycle emissions Residual fuel Value Units Source Log-logistic (2.2, 0.2, 80) Log-logistic (2.3, 0.2, 82) Log-logistic (2.3, 0.3, 83) g CO2e/MJ (LHV) g CO2e/ MJ (LHV) g CO2e/ MJ (LHV) Normal (66, 3.5) Normal (73, 3.9) g CO2e/MJ (HHV) g CO2e/MJ (LHV) (Venkatesh et al. 2011a) (Venkatesh et al. 2011a) (Venkatesh et al. 2011a) Approximate distribution selected; fit to parameters from (Venkatesh et al. 2011b); Brazilian electricity (average) 35 g CO2e/MJ U.S. electricity TRE Electricity MRO Electricity 168 164 200 g CO2e/MJ g CO2e/MJ g CO2e/MJ Calculated from (Coltro et al. 2003) as cited in (Liptow and Tillman 2012) SI. (Wang 2013) (Wang 2013) (Wang 2013) 4.8 5.4 kg CO2e/kg N kg CO2e/kg N Calculated from (Wang 2013) Calculated from (Wang 2013) Triangular (0.003, 0.01, 0.03) kg N2O-N/kg N applied Natural gas life-cycle emissions Electricity Emissions Agrochemicals U.S. Fertilizer production Brazilian Fertilizer Production Direct N2O from synthetic fertilizer and crop residue Volatilization from synthetic fertilizer Indirect N2O from volatized N Triangular (0.03, 0.1, 0.3) Triangular (0.002, 0.01, 0.05) Runoff/Leaching of N from Triangular (0.1, 0.3, 0.8) synthetic fertilizer and crop residue Indirect N2O from runoff Triangular (0.0005, 0.0075, 0.025) (kg NH3-N + kg NOx-N) /kg N kg N2O-N / (kg NH3-N + kg NOx-N) (Klein et al. 2006) kg N runoff / kg N applied kg N2O-N/kg N runoff 67 Energy and Mass Densities Liquids Item Gasoline Diesel/distillate, etc. Residual Fuel Oil Ethanol Ethane (liquefied) Propane (liquefied) n-Butane (liquefied) Isobutane (liquefied) Pentanes plus n-Hexane LHV Energy Density (btu/gal) 112,194a 128,450a 140,353a 76,330a 84,250a 94,970a 90,060a 105,125a HHV Energy Density (btu/gal) 120,439a 137,380a 150,110a 84,530a 91,330b 103,000b 94,620b 110,000b - LHV Energy Density (btu/ft3) 983a 962a 290a HHV Energy Density (btu/ft3) 1,089a 1,068a 343a Mass Density 2,836a g/gal 3,167a g/gal 3,752a g/gal 2,988a g/gal 546.5d kg/m3 582d kg/m3 601.4d kg/m3 593.4d kg/m3 651c kg/m3 655a kg/m3 Gasses Item Natural gas Methane Hydrogen Solids 22a g/ft3 20.3a g/ft3 2.55a g/ft3 Solids Item Glucan/Cellulose Xylan Mannan Galactan Arabinan Lignin Mass Density HHV Energy Density (MJ/kg) 16.9e 17.4e 16.6e 17.2e 16.9e 25.1e Item Glucose Xylose Mannose Galactose Arabinose Non-sugar, non-lignin switchgrass components HHV Energy Density (MJ/kg) 15.6f 15.6f 15.6f 15.5f 15.6f 11.8e 68 Summary Statistics for Natural Gas LDPE Pre-Production Production Processing Steam Cracking Polymerization Mean (kg CO2e/kg LDPE) 0.04 0.22 0.13 0.66 0.79 Standard Deviation 0.01 0.07 0.19 0.24 - Ethylene Subtotal LDPE Total 1.1 1.9 0.31 0.32 Life-cycle Stage 0.23 0.30 1.47 0.37 - Lower 90% CI 0.03 0.16 0.02 0.26 - Upper 90% CI 0.05 0.31 0.36 1.05 - 0.30 0.17 0.61 1.4 1.5 2.3 Coefficient of Variation 69 Summary Statistics for Corn Pathways Corn Ethanol LUC Corn farming Ethanol production Co-product credit Transportation Mean (g CO2e/MJ) 31 43 37 -15 4.0 Standard Deviation 4.6 8.7 3.4 0.18 Coefficient of Variation 0.15 0.2 0.09 0.04 Lower 90% CI 23 31 31 3.7 Upper 90% CI 39 59 42 4.3 Ethanol fuel Total 100 10 0.10 86 120 Life-cycle Stage Corn LDPE LUC Corn farming Ethanol production Co-product credit Transportation Ethanol dehydration Polymerization EOL (growth credit) Mean (kg CO2e/kg LDPE) 1.4 2.0 1.7 -0.61 0.31 0.30 0.79 -3.1 Standard Deviation 0.41 0.41 0.16 0.01 - Coefficient of Variation 0.31 0.20 0.09 0.03 - LDPE Total 2.8 0.49 0.18 Life-cycle Stage Lower 90% Upper 90% CI CI 1.1 1.8 1.5 2.8 1.5 2.0 0.30 0.33 - 2.0 3.7 70 Summary Statistics for Switchgrass Pathways Switchgrass Ethanol Life-cycle Stage LUC Switchgrass farming Ethanol production & electricity credit Transportation Ethanol fuel Total Mean (g CO2e/MJ) 23 12 Standard Deviation 6.6 2.5 Coefficient of Variation 0.29 0.21 Lower 90% Upper 90% CI CI 12 33 8.4 17 -34 3.2 17 0.11 -0.49 0.03 -62 3.1 -7.4 3.4 3.4 17 5.2 -26 31 Switchgrass LDPE Life-cycle Stage LUC Switchgrass farming Ethanol production & electricity credit Transportation Ethanol dehydration Polymerization EOL (growth credit) LDPE Total Mean (kg CO2e/kg LDPE) 1.1 0.56 Standard Deviation 0.31 0.12 Coefficient of Variation 0.29 0.21 Lower 90% CI 0.56 0.39 Upper 90% CI 1.6 0.77 -1.6 0.28 0.30 0.79 -3.1 0.78 0.01 - -0.49 0.03 - -2.9 0.27 - -0.35 0.29 - -1.8 0.81 -0.45 -3.2 -0.5 71 Summary Statistics for Sugarcane Pathways Sugarcane Ethanol Life-cycle Stage LUC Sugarcane farming Ethanol production & electricity credit Transportation Ethanol fuel Total Mean (g CO2e/MJ) 4 17 Standard Deviation 3.7 4.1 1.01 0.23 Lower 90% CI -2.6 11 Upper 90% CI 10 24 -0.88 11 0.89 0.64 -1.0 0.06 -2.7 10 -0.04 12 31 5.5 0.18 22 41 Coefficient of Variation Sugarcane LDPE Life-cycle Stage LUC Sugarcane farming Ethanol production & electricity credit Transportation Ethanol dehydration Polymerization EOL (growth credit) LDPE Total Mean (kg CO2e/kg LDPE) 0.2 0.82 Standard Deviation 0.17 0.19 Coefficient of Variation 1.01 0.23 Lower 90% CI -0.1 0.52 Upper 90% CI 0.5 1.1 -0.041 0.3 0.2 0.3 -3.1 0.042 0.02 - -1.0 0.06 - -0.12 0.3 - 0.00 0.4 - -1.4 0.26 -0.18 -1.8 -1.0 72 Bio-LDPE GHG Equivalence Factor 1 Switchgrass Sugarcane 73 Probability that bio-LDPE achieves same emission reduction as bio-ethanol fuel Bio-LDPE Equivalence Factor 2 Sugarcane Switchgrass Bio-LDPE Equivalence factor 74 Corn Ethanol Importance Analysis 75 Corn LDPE Importance Analysis 76 Switchgrass Ethanol Importance Analysis 77 Switchgrass LDPE Importance Analysis 78 Sugarcane Ethanol Importance Analysis 79 Sugarcane LDPE Importance Analysis 80 Net Emissions – Sensitivity to Surplus Electricity (kg CO2e/kg LDPE)(kg CO2e/46.9 MJ) Bio-product has lower GHG emissions than fossil counterpart Bio-product has higher GHG emissions than fossil counterpart Chemical use (LDPE) Fuel use (gasoline replacement) Switchgrass Sugarcane Corn With Surplus Without Surplus Electricity Sale 81 Sensitivity to Land Use Change Base Case (kg CO2e / functional Unit) No LUC (kg CO2e / functional Unit) Switchover LUC emissions (g CO2e/MJ ethanol) Corn Ethanol +1.3 -1.3 28 Corn LDPE +1.6 -1.0 20 Sugarcane Ethanol -2.7 -2.9 62 Sugarcane LDPE -3.3 -3.4 73 Switchgrass Ethanol -4.1 -5.1 109 Switchgrass LDPE -3.7 -4.7 101 82 Comparison to Other Studies • Corn results – Similar to Mullins et al. (2011) – Higher emissions than EPA (2010) due to DLUC and fertilizer use • Switchgrass results – Lower Emissions than Mullins et al. (2011) due primarily to surplus electricity accounting • Sugarcane results – Higher than Seabra et al. (2011) due to displaced electricity accounting and LUC – Lower than Liptow and Tillman (2012) due to EOL 83 After this are less relevant slides 84 Growing Interest in Bio-based Chemicals • • • • • • Long term sustainability Reduced Environmental Impact Resource Security Unexploited economic and technological potential Corporate image and sales Rural Economic Development 85 Ethylene Production Continues to Grow True (2010). OGJ FOCUS:Global ethylene production. 86 Major plastics and their uses • Annual Production Volumes (Shen et al. 2009) – – – – – – – HDPE: 31 million tons LDPE: 37 million tons PP: 45 million tons PS: 16 million tons PA: 3 million tons PET: 15 million tons PVC: 35 million tons Goodship, V. (2007). Introduction to Plastics Recycling. 87 Bio-Based Chemicals: Possible Challenges • Technical Potential and Unproven Technologies • Environmental Impact • Availability Resources and Competition with Other Needs • Crop Variability • Cost 88 Alternate Strategies • Mode of Substitution – Direct (e.g. Ethylene) – Functional (e.g. PLA) Dornburg et al. (2008) Environmental Science & Technology 42(7): 2261-2267. • Scope of Production – Single Product – Full system (e.g. Biorefinery) Bottom: U.S. DOE (2004). Top Value Added Chemicals from Biomass, Volume 89 I 2. Total Potential of Renewable Feedstocks • Focus on technical potential – long-term vision • Existing studies have focussed on market potential (see figure) • Others focus on potential for energy production Market Potential for biobased bulk Chemicals in Europe (high scenario) Dornburg et al. (2008) Environmental Science & Technology 42(7): 2261-2267. 90 1. Existing Studies on Bio-ethylene • Bos et al. (2010), – – – – – • LCA of polyethylene from 6 different sources No land use change Deterministic Analysis European Context See figure for GHG results; NREU qualitatively similar. Liptow and Tillman (2012) – Comparative LCA of Polyethylene from Brazilian Sugar Cane and Saudi Crude oil – Largely deterministic analysis – European context – Critical role of Land use change – Generally, sugar cane (mildly) preferable for GHG and NREU, while oil route preferred for ACP, EU, CED. Bos et al. (2010). Sustainability aspects of biobased applications, Report 1166. Liptow and Tillman (2012). Journal of Industrial Ecology 16(3): 420-435. 91 Technical Substitution Potential Shen et al. (2010) Biofuels Bioproducts & Biorefining-Biofpr 4(1): 25-40 92 Additional Motivations • Asymmetric Incentives – EISA, RFS – USDA Biopreferred • Competing Uses For Biomass • Competing mechanisms to improve impacts of chemical industry • Existing corporate ventures – Coca Cola, Heinz, P&G… http://coke-stuff.blogspot.com/2013/04/the-bottle.html • Long term sustainability and Carrying Capacity 93