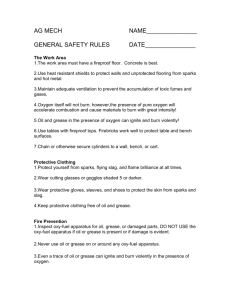

Fire Protection

advertisement

• Cigarette smoking on the roof or around flammables • Sparks from cutting metal deck • Electrical fires or exposed wires • Smoldering asphalt under roof • Kettle fires • Storage of flammables near heat sources • Mechanical equipment fires • Flash over with primer wash • Building fire caused by customer 3 Components of fire: 1. Fuel 2. Heat 3. Oxygen All three components are needed for a fire to survive! Take one of the three away, the fire will not survive! • • • • CLASS A - Ordinary Combustibles CLASS B - Flammable or Combustible Liquids CLASS C - Electrical CLASS D - Combustible Metals Examples: • Paper • Insulation • Dried Adhesives • Fiberboard • Clothing • Wood Deck Examples: • • • • • • Gasoline Primer Wash Splicing Cement Adhesives Coatings Propane Points to remember: • Never use water to extinguish! • Check all cords and equipment before use • De-energize when not in use • Exposed wires are a fire hazard • Class A - For class A fires only • Class B - For class B fires only • Class AB - For both class A and B fires • Class ABC - For class A, B, and C fires What type of fire is this going to be? Which is the proper extinguisher to use for suppression of the previous fire? 1. 2. 3. P. A. S. S. System 1 Pull - Pull pin 2 Aim - Aim nozzle at base of the fire 3 Squeeze - Squeeze the handle together 4 Sweep - Sweep back and forth • Fire extinguishers can save lives and property • Only attempt to extinguish a fire if it is safe and you have been trained on proper use • Evacuate the roof if the fire is out of control • • • • • * Recommended Procedure Shut the lid Shut off the fuel source Remember to do both! Use extinguisher when: Fire is no longer contained in kettle Fire is out of Control NEVER use water! • Review escape plan before work begins • Never set up the kettle near access to the roof • Keep the fire extinguishers in your work area • Foremen, keep cell phone on you at all times • Proper Torch Assembly – – – – – Follow all Manufacturer’s Recommendations Use only approved connection equipment Hand tighten parts and do not force connection Use open end wrench to complete assembly Do not use any type of thread sealant as they may be flammable • • • • Inspect all equipment for damage before use Inspect propane cylinder for dirt Close cylinder valve tightly Attach torch following Manufacturer’s Recommendations • Complete leak test using soapy water – Leaks will cause bubbles to form • If leak is detected, close cylinder valve and disconnect all parts – Attempt to reassemble – If leaks still exist, discontinue use and replace torch • Never use open flame to check for leaks! • Never use any type of mastic or putty between parts of a torch. • Wear required PPE – Eye protection, gloves, long clothing to cover skin • • • • • Prepare work area by clearing away debris Have extinguishers present and secure propane tank Alert other workers and keep them away Open cylinder and keep torch away from body Use striker to ignite gas and adjust flame – NEVER USE CIGARETTE LIGHTERS OR MATCH • • • • • • Always assume a torch at rest is lit Use leg stand to support torch Shut torch off when not in use Never leave torch unattended Never operate within 3 feet of other workers Never point torch towards flammable objects or areas you can not see clearly • Use caution when using torch around: – Roof openings, units & drains – Roofing materials and combustible deck • Never turn propane cylinder on its side – This does not increase fuel supply and is dangerous • Never apply open flame to defrost cylinders • Use caution when walking backwards – Use all required fall protection – Be aware of your surroundings – Have another employee serve as spotter • It is not recommended to use a torch to dry a roof or a deck – Using a torch in this manner is approved by NRCA/ CERTA for only specific situations. – Fire can enter a building from anything that disturbs the field. • • • • • • • Always disconnect torches at end of work day Inspect all components for damage Replace damaged components Set torch on side and close cylinder valve Squeeze torch trigger to purge remaining gas Close all valves and disconnect torch Properly store equipment & secure cylinders • Torches that will not be used for more than 30 days should be completely disassembled for storage. • Propane Cylinders & Valves – Manufactured with safety controls • Protective Collar • Cylinder Valve • Foot Ring • Propane Cylinders – Protective Collar • Guard to protect cylinder valve • Designed to withstand tipping or damage – 30 pound weight dropped from 4 feet • Do not use if protective collar is missing • NEVER ATTACH RIGGING TO THE COLLAR • Propane Cylinders – Cylinder Valve • Contains OPD (Overfill Protection Device) – Will prevent against overfilling of tank – Required for all propane cylinders • Always use hand wheel to adjust controls – Open slowly and do not force – Remove from service if hand wheel is damaged • Pressure relief valve – Designed to protect cylinder – Do not try to repair leaking valves • Propane Cylinders – Foot Ring • Cylinders must remain upright • Foot ring helps to stabilize • Cylinders must be secured – Guard Rail – Milk Crate – Bungee Cord • When cutting through metal deck and during the use of torch work: – Mark off 10ft area below – Have a crew member stand below outside marked area to watch for smoke and fire – Supply him with a hard hat, safety glasses, and a fully charged ABC rated fire extinguisher – Should remain on duty for at least one hour past work incase of smoldering • All flammable and combustible materials must be properly labeled • Labels should be kept clean and easily noticeable • All D.O.T. vehicles must have proper placards • Never remove or alter labels FIRE HAZARD Flash Points: 0 -Will not burn 1 -Above 200oF 2 -Below 200oF 3 -Below 100oF 4 -Below 73oF Building Tarped No Windows Hot Pipe Secure to 8’ Rail Asphalt Stored Neatly Area Flagged Off Correctly Propane Secure 10’ from Flame Rubber Matting Under Kettle Proper PPE Worn 20 lb. Fire Extinguisher Wheels Chalked • Area flagged off • 20 lb. Fire extinguisher present • Fuel set 10 feet from ignitable source & secured in place • Plywood under kettle if set on new roof • Proper PPE worn PPE Required for Kettle Operations: • Hardhat with Attached Face Shield - the face shield prevents splashes from reaching the face and upper neck • Leather Gloves - cuffs must be long enough to be tucked under sleeves • Long Pants with No Cuffs - cuffs on pants may hold asphalt and allow it to burn you • Long Sleeved Sweatshirt - preferably hooded to protect the back of your neck While working with hot asphalt on the roof employees must wear:Leather gloves, Safety glasses, Long sleeved shirt, Long pants w/ no cuffs, and proper boots * Never use glue buckets or primer wash cans to transport hot, only hot buckets or approved containers Note: When pouring asphalt from pipe, a face shield is also required to be worn • Always use caution with flammable materials and open flames • Think Safety First to avoid burns • Fire watch is needed for spark generating work • Only use strikers to light torches • Never use gasoline to clean hands • Only you can prevent roof fires!