ppt

Chapter 9

Sections:9.2, 9.3, 9.4, 9.5

Chapter 9: Phase Diagrams

Why study?

One of the reason why a knowledge and understanding of phase diagrams is important to the engineers related to the design and control of heat treating processes.

Some properties are functions of their microstructures, and, consequently, of their thermal histories.

Definitions and Basic Concepts

Components : Pure metals and/or compounds of which an alloy is composed

–

Example: in a copper-zinc brass, the components are Cu and Zn.

System

–

First meaning : refer to a specific body of material under consideration ( e.g., a ladle of molten steel)

–

Second meaning : relate to the series of possible alloys consisting of the same components, but without regard to alloy composition (e.g., the iron-carbon system)

Solid solution : Consists of atoms of at least two different types

– Solute an element or compound present in a minor concentration

– Solvent

an element or compound in greater amount; host atoms.

– Solute atoms occupy either substitutional or interstitial positions in the solvent lattice

– Crystal structure of the solvent is maintained

9.2 Solubility Limit

Solubility Limit : The maximum concentration of a solute atoms that may dissolve in the solvent to form a solid solution at some specific temperature.

The addition in excess results in the formation of another solid solution or compound that has a distinctly different composition.

Example : Sugar-Water (C

12

H

22

O

11

-H

2

O) system

– Initially, as sugar added to water, a solution of syrup forms.

–

As more sugar is added, solution becomes more concentrated

– Solution becomes saturated with sugar Solubility limit is reached

– Not capable to dissolving more

further addition simply settle to the bottom

– System now consists of two separate substances :

» A sugar-water syrup liquid solution, and

» Solid crystals of undissolved sugar

9.3 Phases

Phase: defined as a homogeneous portion of a system that has uniform physical and chemical characteristics.

Every pure material is considered to be a phase

– Also every solid, liquid, and gaseous solution

– e.g., syrup solution is one phase, and solid sugar is another

If more than one phase is present, it is not necessary that there be difference in both physical and chemical properties :

– A disparity in one or both is sufficient

– e.g., water and ice in a container ( two phase, identical chemically)

–

When a substance can exist in two or more polymorphic forms (e.g. having both FCC abd BCC)

each structure is a separate phase because of difference in physical properties.

A single-phase system is termed “ homogeneous ”

Systems composed of two or more phases are termed “ mixture ” or heterogeneous systems”.

Most metallic alloys, ceramics, polymeric, and composite systems are heterogeneous.

Ordinarily, in multiphase systems

– The phases interact such that the property is different and more attractive than individual phases.

9.4 Microstructure

Physical properties and mechanical behavior depend on the microstructure .

In metal alloys, microstructure is characterized by

– Number of phases present

–

Their proportions

– The manner they are distributed or arranged

The microstructure of an alloy depends on such variables as

– Alloying elements present

–

Their concentrations

– The heat treatment

Microstructure studies :

– surface preparation (Polishing and etching)

– For two phase alloys, one phase may appear light and other dark

9.5 Phase Equilibria

Free energy is a function of the internal energy of a system, and also of the randomness or disorder of the atoms or molecules (or entropy).

A system is at equilibrium if its free energy is at a minimum under some specified combination of temperature, pressure, and composition.

In macroscopic sense, this means that the characteristics of the system do not change with time but persist indefinitely

The system is stable

A change in temperature, pressure, and/or composition in equilibrium

increase in free energy another equilibrium state whereby the free energy is lowered.

Phase equilibrium refers to equilibrium as it applied to systems in which more than one phase may exist.

Example :

–

Sugar-water syrup is contained in a closed vessel solution is in contact with solid sugar at 20 o C

–

If system is in equilibrium,

»

Composition of syrup is 65wt% C

12

H

22

O

11

-35wt% H

2

O (Fig 9.1)

»

Amount and composition of syrup and sugar will remain constant

– If temperature is raised to 100 o C

» Equilibrium is temporarily upset

» Solubility limit of sugar has increased to 80 wt%

»

Some of the solid sugar will dissolve until new equilibrium is reached

Metastable state :

– Nonequilibrium state

– A state of equilibrium is never completely achieved because the rate of approach to equilibrium is extremely slow

– Common in many metals or solid solutions

–

Persist indefinitely with imperceptible changes with time.

Metastable structure :

– More practical than equilibrium

– Some steel and aluminum rely on this for heat treatment designing

Chapter 9

Sections: 9.6

Equilibrium Phase Diagrams

Equilibrium Phase diagram :

– Represents the relationships between temperature and the compositions and the quantities of phases at equilibrium.

– Also known as phase, equilibrium or constitutional diagram

A binary alloy is one that contains two components.

Temperature and composition are the variable parameters for binary alloys.

Of more than two components , phase diagrams become extremely complicated and difficult to represents

9.6 Binary Isomorphous systems

Phase diagram of the

copper-Nickel system

is shown in Fig 9.2a.

Ordinate

Temperature

Abscissa

composition

Composition ranges from 0 wt% Ni (100 wt% Cu) to 100 wt% Ni (0 wt% Cu)

Three different phase

regions, or fields, appear

– An alpha ( a

) field

– A liquid (L) field

– A two-phase ( a

+L) field

Liquid L: homogeneous liquid solution composed of both copper and nickel

a phase: a substitutional solid solution consisting of both Cu and Ni atoms, and having an FCC crstal structure.

Isomorphous: complete liquid and solid solubility of two components

Copper-Nickel system is Isomorpous

– At temperatures below about 1080oC, mutually soluble in solid state for all compositions

– Complete solubility is due to same crystal structure (FCC), nearly identical atomic radii and electronegativities, and similar valences

Nomenclature

– For metallic alloys, solid solutions are designated by a, b, g

, etc.

– Liquidus line: liquid phase at all temperature and composition above this line

– Solidus line: solid phase below this line at all temperatute and composition

Liquidus and solidus lines intersect at two extreme points

– Correspond to melting temperature of pure components

–

Copper (1085 o C) and Nickel (1453 o C)

Heating of pure copper

–

Moving vertically on left-temperature axis

– Remains solid until its melting temperature is reached

– No further heating possible, until this transformation is complete

For any composition other than pure components

– Melting phenomenon occurs over the range of temperature between the solidus and liquidus lines

– Both solid a and liquid will be in equilibrium within this range

Interpretation of Phase Diagrams

For binary system of known composition and temperature that is in equilibrium, at least three kinds of information are available:

1.

The phases that are present

2.

The composition of these phases

3.

The % or fraction of the phases

1.0 Phases present

– Relatively simple

– Example (refer to Fig 9.2a),

60 wt% Ni-40 wt% Cu at 1100 o C Point A a phase

35 wt% Ni-65 wt% Cu at 1250 o C Point B a

+ liquid phases

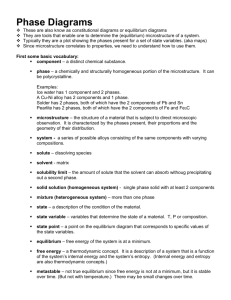

PHASE DIAGRAMS

• Tell us about phases as function of T, C

o

, P.

• For this course:

--binary systems: just 2 components.

--independent variables: T and C

o (P = 1atm is always used).

• Phase

Diagram for Cu-Ni system

Adapted from Fig. 9.2(a), Callister 6e.

(Fig. 9.2(a) is adapted from Phase

Diagrams of Binary Nickel Alloys, P. Nash

(Ed.), ASM International, Materials Park,

OH (1991).

5

PHASE DIAGRAMS: # and types of phases

• Rule 1: If we know T and C

o

, then we know:

--the # and types of phases present.

• Examples:

Cu-Ni phase diagram

Adapted from Fig. 9.2(a), Callister 6e.

(Fig. 9.2(a) is adapted from Phase

Diagrams of Binary Nickel Alloys, P. Nash

(Ed.), ASM International, Materials Park,

OH, 1991).

6

PHASE DIAGRAMS: composition of phases

• Rule 2: If we know T and C

o

, then we know:

--the composition of each phase.

• Examples:

Cu-Ni system

Adapted from Fig. 9.2(b), Callister 6e.

(Fig. 9.2(b) is adapted from Phase Diagrams of

Binary Nickel Alloys, P. Nash (Ed.), ASM

International, Materials Park, OH, 1991.)

7

PHASE DIAGRAMS: weight fractions of phases

• Rule 3: If we know T and C

o

, then we know:

--the amount of each phase (given in wt%).

• Examples:

Cu-Ni system

W

L

R

S

S

43

35

43

32

73 wt %

W a

R

R

S

= 27wt% Adapted from Fig. 9.2(b), Callister 6e.

(Fig. 9.2(b) is adapted from Phase Diagrams of

Binary Nickel Alloys, P. Nash (Ed.), ASM

International, Materials Park, OH, 1991.)

8

THE LEVER RULE: A PROOF

• Sum of weight fractions:

• Conservation of mass (Ni):

WL

W a

Co

1

WLCL

• Combine above equations:

W a C a

• A geometric interpretation:

moment equilibrium:

WLR

W a

S

1

W a solving gives Lever Rule

9

Composition need to be specified in terms of only one of the constituents

– For example, composition of Ni is used

– Identical results if composition of Cu is used

C o

= 35 wt% Ni

C a

= 42.5 wt% Ni

C

L

= 31.5 wt% Ni

W

L

= ( 42.5 – 35) / (42.5 – 31.5) = 0.68

W a

= (35 – 31.5) / (42.5 – 31.5) = 0.32

Volume fraction : See equations 9.5 – 9.7

V a

v a v

a v b

Volume Fractions

V b

v a v b

v b

V a

W a

a

W a

a

W b

b

V b

W a

a

W b

b

W b

b

W a

V a

a

V a

a

V b

b

W b

V a

V b

b a

V b

b

Development of Microstructure in Isomorphous alloys

-- Equilibrium Cooling

35 wt% Ni-65wt% Cu as cooled from 1300 o C

Cooling very slowly phase equilibrium is maintained

Cooling

Moving down

At 1300 o C , completely liquid

At b (1260 o C), solidification starts

At d (1220 o C), solidification completes

Development of Microstructure

-- Non-Equilibrium Cooling

Extremely slow cooling not valid

Temperature change readjustment in composition diffusional processes

Diffusion rates are low for the solid phase and, for both phases, decrease with diminishing temperature

Practical solidification processes , cooling rates are much too rapid to allow these compositional readjustments and maintenance of equilibrium different microstructure develops

At b’, a phase begin to form [ a

(46Ni)]

At c’ ,

– liquid composition: 29wt% Ni-71 wt% Cu

– Solid phase: 40 wt% Ni-60 wt% Cu [ a

(40Ni)]

– Since diffusion in solid is relatively slow, a phase formed at b’ has not changes composition appreciably

still [ a

(46Ni)]

– Composition of a grains continuously changes radially from 46 wt%

Ni at center to 40 wt% Ni at the outer grains average composition

(say 42 wt%Ni)

– Solidus line has shifted

Chapter 9

Sections: 9.7

9.7 Binary Eutectic Systems

Binary Eutectic Phase Diagram

– Another type of common and relatively simple phase diagram

–

Figure 9.6 shows for the copper-silver system

Features of Binary Eutectic Phase Diagram

Feature 1: Three single-phase regions ( a

, b

, and liquid )

– The a phase: solid solution rich in copper, silver as solute, FCC

–

The b phase: solid solution rich in silver, copper as solute, FCC

–

Solubility in each of these solids phases is limited

Solubility limit for a phase

–

Line ABC ( Increases with temperature, maximum, decreases to minimum)

– Solvus line (BC)

–

Solidus line (AB)

Solubility limit for b phase

–

Line FGH ( Increases with temperature, maximum, decreases to minimum)

–

Solvus line (GH)

– Solidus line (FG)

Line BEG is also solidus line

– Maximum solubility in both a and b phases occur at 779 o C

Feature 2:

a

+ L

b

+ L

a

+ b

Three two-phase regions

As silver is added to copper,

– The melting temperature of copper is lowered by silver additions.

–

Line AE: the liquidus line

Same is true as copper is added to silver

Point E is called the invariant point (C

E

= 71.9 wt% Ag, T

E

= 779 o C)

At E, an important reaction occurs

–

Upon cooling , a liquid phase is transformed into a and b solid phases

– The opposite reaction occurs upon heating

–

This is called eutectic reaction ( Eutectic means easily melted)

–

C

E and T

E represents eutectic composition and temperature

– Horizontal solidus line at T

E is called the eutectic isotherm

The eutectic reaction, upon cooling , is similar to solidification of pure components:

– Reaction proceeds to completion at a constant temperature

– Isothermal at T

E

– Solid products of eutectic solidification is always two solid phases

Another common eutectic system is that for lead and tin

– The phase diagram is shown in Figure 9.7

Example 9.2

Example 9.3

Development of Microstructure in Eutectic Alloys

Depending on composition, several different types of microstructures

These possibilities considered in terms of the lead-tin phase diagram

–

Figure 9.7

First case: Composition C1

Range:

Composition ranging between a pure metal and the maximum solid solubility for that component at room temperature (20 o C)

Lead-rich alloy (0-2 wt% Sn)

Slowly cooled down

Second Case: Composition C2

Range:

Composition ranging between the room temperature solubility and the maximum solid solubility at the eutectic temperature.

Corresponds: 2 wt% Sn to 18.3 wt% Sn

Third Case: Composition

C3

Solidification of the eutectic composition

Corresponds: 61 wt% Sn

The microstructure at i is known as eutectic structure.

Lamellae :

– The microstructure of a solid consisting of alternating layers

– Shown in Figure 9.12

Fourth Case:

Composition C4

All composition other than the eutectic composition

At m, a phase will be present in both :

– Eutectic a

– Primary a

Microconstituents

– An element of the microstructure having an identifiable and characteristic structure.

– At m, two microconstituents ( primary a and the eutectic structure )

Relative amounts

of both eutectic and primary a microconstituents

Eutectic microconstituents forms from liquid having eutectic composition (61 wt% Sn, Fig 9.11, point i)

Apply lever rule using tie line

Eutectic fraction

W e

= W

L

= P / (P+Q)

Primary

a

fraction

W primary a

= Q / (P+Q)

Total

a

fraction (primary plus eutectic)

W a

= (Q+R) / (P+Q+R)

Total

b

fraction (primary plus eutectic)

W b

= P / (P+Q+R)

Chapter 9

Sections: 9.8, 9.9, 9.13

9.8 Equilibrium Diagrams Having Intermediate Phases or

Compounds

Terminal solid solutions

– Solid phases exist over the composition ranges near the concentration extremities of the phase diagram

– Examples: Copper-Silver system (Figures 9.6)

– Lead –Tin system (Figure 9.7)

Intermediate solid solutions

– Intermediate phases

– Solid phases at other than the two composition extremes

– Example : Cupper-Zinc system (Figure 9.17)

Intermetallic compounds

Discrete intermediate compounds rather than solid solutions

– These compounds have distinc chemical formulas

9.9 Eutectoid and Peritectic Reactions

Eutectoid Reaction

– Invariant point E, Figure 9.19

–

Upon cooling, a solid phase transforms into two other solid phases

– Reverse reaction occurs on heating

– Horizontal line at 560 o C: eutectoid or eutectoid isotherm

– Eutectic liquid on cooling transforms into two solids

– Importance: iron-carbon diagram

Peritectic Reaction

– Another invariant reaction (Point P, Figure 9.19)

– Upon heating, one solid phase transforms into a liquid phase and another solid phase

– ( d

+ L)

on cooling

e

THE IRON-CARBON SYSTEM

9.13 The iron-iron carbide (Fe-Fe

3

C) phase diagram

Of all binary alloys, the most important is the iron-carbon phase diagram.

– A portion is shown in Figure 9.22

– Practically all steels and cast irons have less than 6.70 wt% C.

Pure iron:

Upon heating, experiences two changes in crystal structure before it melts

– At room temperature , the stable form ( ferrite or a iron ) has a BCC.

– At 912 o C , Ferrite experiences polymorphic transformation FCC austenite , or g iron .

– At 1394 o C , reverts back to a BCC phase ( d ferrite )

– At 1538 o C , d ferrite melts

At 6.7 wt% C

– Intermediate compound iron carbide , or cementite (FE

3

C), is formed.

– 6.7 wt% C corresponds to 100 wt% Fe

3

C

Carbon is an interstitial impurity in iron

– Forms a solid solution with each of a and d ferrites and g austenite

BCC a ferrite

– Small concentration of carbon are soluble (0.022 wt% at 727 o C)

–

Even though small concentration, significantly influences mechanical properties

– Relatively soft, magnetic at temperature below 768 o C, density of 7.88 g/cm 3

– Figure shows photomicrograph

Austenite

or g phase iron

– Not stable below 727 o C

– FCC structure

– Maximum solubility of carbon in austenite: 2.14 wt% C at 1147 o C.

–

Figure 9.23b shows photomicrograph

BCC d

ferrite

is virtually same as a ferrite

– Stable only at relatively high temperatures no technological importance

Cementite (Fe

3

C) forms when the solubility limit of carbon in a ferrite is exceeded below 727 o C

– Coexist with g phase between 727 and 1147 o C

–

Cementite is very hard and brittle

strength of steel is enhanced by its presence

One eutectic reaction for iron-carbon system

– At 4.30 wt% C and 1147 o C

L on cooling g

+ Fe

3

C

L

on heating

g

+ Fe

3

C

Eutectoid invariant point at 0.76 wt% C and 727 o C g

(0.76 wt% C) on cooling a

(0.022 wt% C) + Fe

3

C(6.7 wt%C) g

(0.76 wt% C)

on heating

a

(0.022 wt% C) + Fe

3

C(6.7 wt%C)

Chapter 9

Sections: 9.14, 9.15

9.14 Development of Microstructures in Iron-Carbon Alloys

Microstructure depends on both the carbon content and heat treatment .

Discussion confined to very slow cooling equilibrium is continuously maintained.

Phase change from g austenite region into the a

+ Fe

3

C phase field

– Relatively complex , similar to eutectic system

– Consider cooling of an alloy of eutectoid composition

( Point a at 0.76 wt% C and 800 o C)

– No changes until the eutectoid temperature (727 o C)

–

At b, pearlite microstructure

– Figure 9.25, photomicrograph of eutectoid steel showing the pearlite.

The pearlite exists as grains

– Often termed colonies

– Layer orientation is same in each colony

– Thick light layers ferrite phase

–

Thin lamellae, mostly dark

cementite

– Ferrite

soft and ductile

Cementite hard and brittle

Pearlite intermediate between ferrite and cementite

Hypo-Eutectoid Alloys

Consider a composition Co to the left of eutectoid

– Between 0.022 and 0.76 wt% C

– Termed a hypoeutectoid (less than eutectoid) alloy

– Cooling is shown in Figure 9.27

At d , about 775 o C, a

+ g phase

– Composition of ferrite ( a iron) changes along MN

» Slight changes

– Composition of austenite ( g iron) changes dramatically along MO

At f , just below the eutectoid

– All g

-phase having eutectoid composition transforms to pearlite

–

No change in a

-phase (ferrite )

– Ferrite exist in two phases :

»

Eutectoid ferrite

ferrite that is present in pearlite

» Proeutectoid ferrite pre- or before eutectoid; formed above Te

Figure 9.28: photomicrograph of a 0.38 wt% C steel

– Large white regions: proeutectoid ferrite

–

Pearlite

» Dark regions

» Spacing between a and

Fe

3

C layers vary from grain to grain

Hyper-Eutectoid Alloys

Right side of eutectoid ( between 0.76 and 2.14 wt% C)

At g , only g phase (austenite ) of composition C

1

Upon cooling at h , g g

+ Fe

3

C phase field

– Proeutectoid cementite that forms before the eutectoid reaction

– Cementite composition remains constant as the temperature changes

– Austenite composition changes along line PO towards eutectoid

Below eutectoid temperature at i ,

– All remaining austenite of eutectoid composition pearlite ( a

+Fe

3

C)

– Microconstituents of resulting microstructure

pearlite and proeutectoid cementite (Fig 9.30)

Photomicrograph of hypereutectoid alloys

Photomicrograph of 1.4 wt% C steel is shown in Fig. 9.31

– Consists of pearlite and proeutectoid cementite

–

Proeutectoid cementite appears light

– Same appearance as proeutectoid ferrite

difficulty in distinguishing between hypoeutectoid and hypereutectoid steels on the basis of microstructure

Photomicrograph of hypereutectoid alloys (Contd.)

Comparison with hypoeutectoid alloys photomicrograph

Relative amounts for hypoeutectoid steel alloys

Using lever rule

Tie line extends between 0.022 and 0.76 wt% C

Fraction of pearlite,

W p

= T / (T+U) = (C o

’ – 0.022) / (0.76 – 0.022)

Fraction of proeutectoid a

,

W a

’

= U / (T+U) = (0.76 - C o

’

) / (0.76 – 0.022)

Relative amounts for hypereutectoid steel alloys

Using lever rule

Tie line extends between 0.76 and 6.7 wt% C

Fraction of pearlite,

W p

= X / (V+X) = (6.70 – C

1

’

) / (6.70 - 0.76)

Fraction of proeutectoid cementite (Fe

3

C)

W

Cementite

’

= V / (V+X) = (C

1

’

- 0.76 ) / (6.70 - 0.76)

9.15 The Influence of Other Alloying Elements

Other alloying elements (Cr, Ni, Ti, etc.) bring about dramatic changes

Changes in the position of phase boundaries and shapes

One important change

shift in eutectoid position w.r.t temperature and composition

These effects are illustrated in Figures 9.32 and 9.33