Introduction

advertisement

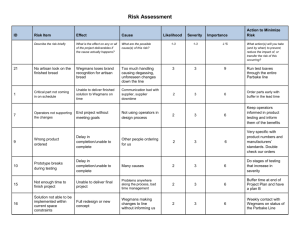

PROJECT STATUS UPDATE P10711 & P10712 Andreana Crance, Industrial & Systems Engineering Matt Syska, Industrial & Systems Engineering PROJECT STATUS UPDATE Project Name Wegmans SD Projects 1 & 2 Project Number P10711 & P10712 Project Family R09170 Track Modern Food Processing and Bakery Technology for Lean Production Systems Start Term 2009-2 End Term 2009-3 Faculty Guide Dr. John Kaemmerlen (ISE) Technical Lead Phil Bryan Primary Customer Wegmans Distrubution Center, Scott Young PHASE 0: PLANNING: MISSION STATEMENT Product Description /Project Overview The aim of this project is to improve a specific process in the Wegmans manufacturing facility., focusing on the Central Bakeshop or Culinary Innovation Center. The overall outcome of the project is to identify and implement process improvements in order to increase efficiency, and therefore throughput of the process. Key Business Goals/Project Deliverables The primary business goals of this process change is to: Create standard work processes for different areas of facility Standardize procedures (i.e. changeovers, storage) Utilize workers’ time in a more efficient way Improve overall efficiency of facility in order to make a greater profit Improve safety conditions for all workers Primary Market /Project Opportunities Wegmans central bakeshop and culinary innovation center in Rochester, NY Secondary Market /Project Opportunities Similar Wegmans production facilities Stakeholders Wegmans Central Bakeshop and Culinary Innovation Center in Rochester, NY Scott Young and Wegmans’ engineering group Bakery and Culinary workers whom are effected by the changes Raw Material and Ingredients Providers Wegmans Distribution Center Community Community that purchases the products PHASE 1: CONCEPT DEVELOPMENT IDENTIFY CUSTOMER NEEDS - INTERVIEWS Primary Customer(s) Wegmans Engineering Team Scott Young: Provided many ideas for new projects for 2009 year. Provided insight into the projects. Additional resources include: Mike Least (Manufacturing Engineer), Chris Isaacson, Jamie Rothfuss (Industrial Engineer) In next 1-2 weeks: Contact Mike, Chris and Jamie to narrow down projects Other Stakeholder(s) Wegmans Bakery and Culinary Workers Following facility tour and project selection: Must talk with bakery and culinary workers to get their input and feedback Past Senior Design Team(s) P09711 – Automation and Improvement of Packaging on the Cookie Line Automating a perviously all hands-on process P09712 – Commericial Roll Line Shrink Reduction Decrease amount of wasted rolls and improve effeciency of process P09713 – Bread and Roll Scaling Room Make overall layout of room more efficient and effective for employees PROJECT CONTEXT Wegmans operates a Central Bakeshop and Culinary Innovation Center in Rochester, NY. 2008-2009 AY first year for Wegmans projects. DPM students in Fall 2008 defined 6 potential projects. Packaging Automation/Improvement for Cookie Line Fresh Bread and Roll Scaling Room Commercial Bread Line Shrink Reduction ERP ERP Implementation Implementation Ergonomics Ergonomics Universal System Universal Rack System CURRENT WORK P09711 – Cookie Line Automation P09712 – Commercial Bread Line Shrink Reduction P09713 – Fresh Bread and Roll Scaling Room FUTURE WORK BASED ON CURRENT WORK Re-evaluated projects defined in Fall 2008 DPM with Wegmans: Packaging Automation/Improvement for Cookie Line Fresh Bread and Roll Scaling Room Commercial Bread Line Shrink Reduction ERP Implementation Implementation ERP Ergonomics Ergonomics Universal Rack Universal Rack System System AFFINITY DIAGRAM – RAW DATA FROM CUSTOMERS AND STAKEHOLDERS Lean No Standardization Safety Ergonmics Concerns Material Handling Layout Design Worker Relations Transport of raw materials New Equiptment More efficient set ups Culinary Innovation Center more strict Manual process operation improvements Easily cleaned Must meet health code High Volume, High Mix of products Noise Issues Mixing Storage Utilization Batch Processing & Bulk Savings Preventative Procedures Transferrable Low cielings Process Improvement Cost effective Labor Effeciency Savings Loading Procedures Sanitary Requirements Customizable Resource Usage Ease of Use Scalable Environmentally friendly OBJECTIVE TREE – WHY DOES THE CUSTOMER NEED THIS PRODUCT? This Product or Process Needs to … Lean Processes Improve Loading Procedures Scalable solution Safety Proper utulization of resoruces Ensure safety of workers Material Handling Handle variety of materials Improve storage of large raw material Stop problems before they occur Reduce current noise issues Layout Transferrable Effeciently use old and new space Enable further expansion Cost effective changes FUNCTION TREE – WHAT DOES THIS PRODUCT NEED TO DO? Improve Process’ at Wegmans Central Bakeshop and Culinary Innovation Center Reduce time to load and unload machines Lean Safety Able to be sized up due to high demands Be proactive in solving safety problems – report any issues Perform to the bottleneck Perform to the set standards Material Handing Handle up to 2,000lbs of material Accessible and cost efficient storage Not bring noise levels above acceptable standard Layout Able to move facility to facility without failing Improve flow of goods and people Effectivley use space in order to allow for expansion Be cost effective PRELIMINARY IDEAS Ergonomics and Design of Tumbler Transport Storage Utilization Standardization Bakery Patisserie Efficiency Noise Exposure Ergonomics Issue Handling System for Meat Marinade Bakery Bulk Bag Storage Bakery Cheesecake Process Improvement Batch Prep Room Simplification Marinade Package Labeling Improvement Tote (basket) Loading Process Improvement PROJECT RISKS + RESTRAINTS Wegmans staff very busy Must be completed in 22 weeks Wegmans does not have hard deadlines Working with peoples’ workplaces FUTURE PLAN WHERE DO YOU GO FROM HERE? Action Date Meet with faculty guide and tech lead to discuss possible projects Set up facility tour with Wegmans Contacts Week 6/7 Analyze Projects Week 7/8 Discuss Top Project Choices with Wegmans Week 8/9 Week 6/7