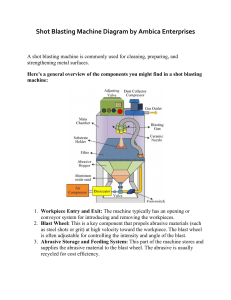

Why Shot Blasting is Required - Ambica Enterprises Discover the importance of shot blasting at Ambica Enterprises. Our surface preparation techniques ensure optimal cleaning, rust removal, and coating adhesion. Enhance material longevity, strength, and quality with our efficient and environmentally friendly solutions. Trust Ambica Enterprises for top-notch shot blasting services in various industries. Shot blasting is a surface preparation technique used in various industries for multiple reasons. Ambica Enterprises might employ shot blasting for the following purposes: 1. Surface Cleaning: Shot blasting is highly effective in removing contaminants, rust, scale, and other impurities from the surface of materials. It ensures a clean and debris-free surface, which is 2. 3. 4. 5. 6. 7. 8. 9. essential for subsequent processes such as painting, coating, or welding. Rust and Corrosion Removal: Metal surfaces are often prone to rust and corrosion, especially when exposed to harsh environments. Shot blasting helps in removing existing rust and corrosion, preventing further deterioration and extending the lifespan of the material. Preparation for Coating: Before applying paints, coatings, or other protective finishes, it is crucial to have a properly prepared surface. Shot blasting provides an ideal surface profile by removing contaminants and creating a roughened texture, ensuring better adhesion of coatings. Surface Profiling: Shot blasting can be used to create specific surface profiles or textures on materials. This is especially important in industries where surface roughness is a critical factor, such as in construction, where a certain texture is required for concrete adhesion. Removal of Old Coatings: In cases where existing coatings or layers need to be removed, shot blasting is an effective method. It strips away old paint, coatings, or other materials, preparing the surface for new applications. Improved Mechanical Properties: Shot blasting can enhance the mechanical properties of materials by inducing compressive stress on the surface. This can improve fatigue resistance and increase the overall strength of the material. Deburring: In manufacturing processes, metal components may have sharp edges or burrs. Shot blasting helps in removing these burrs, resulting in smoother and safer surfaces. Welding Preparation: Before welding, it is essential to have a clean and properly prepared surface. Shot blasting removes contaminants and oxides, ensuring a better welding environment and stronger welds. Efficient and Environmentally Friendly: Compared to some traditional methods, shot blasting is a relatively efficient and environmentally friendly process. It minimizes waste and is often a preferred method for surface preparation. In summary, shot blasting is a versatile and essential process in industries where the quality of the surface is crucial for the performance, longevity, and appearance of materials and products. Buy Shot Blasting Machine Online in India: Contact Us Name - Ajay Singh CEO of Ambica Enterprises Email - inquiryi46@gmail.com Mobile Number - +91-9653765900 Company Name - Ambica Enterprises Address - Jodhpur, Rajasthan, India Website - 1: https://www.shotblastingmachines.in/ Website - 2: https://shotsblastingmachine.com/ Thanks! ❤️❤️❤️