Plankton Culture for Feeding Larval Fish and Shellfish

advertisement

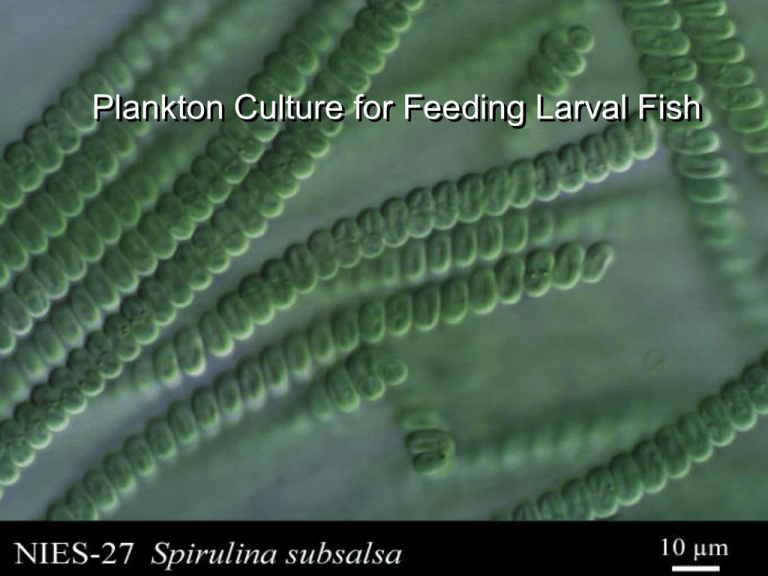

Plankton Culture for Feeding Larval Fish Introduction • You’ve got larval fish!! Good job!! • Now what?? • If you’ve researched then it shouldn’t be a big deal, because you’re ready to feed those little critters! • Mostly food for larval fish is size dependant. If they can get it down and it doesn’t damage their gut lumen, then it might be a good food. • Not all larval food is created equally. We’ll consider micro plants as first feeding options, then progress toward larger and larger prey items. Microalgae (phytoplankton) • Nutritionally, microalgae are a good source of macro and micronutrients for some larval fish. • Fatty acids and pigments gained from ingestion of microalgae are especially important for larval fish health. • Table 1 and 2 highlights some of these features. Table 1. Approximate percent nutritional composition of several microalgae fed to larval fish. Species Protein Fat Carb Ash Chaetoceros muelleri 35 30 20 15 Pavlora virdis 60 16 16 8 Tetraselmus tetratheie 30 5 27 38 Isochrysis galbana 46 22 22 10 Table 1 Species Nannochloropsis oculata Pavlora lutheir Skeletonema costatum Phaeodactylum tricornutum Tetraselmus tetratheie Isochrysis galbana Isochrysis aff galbana EPA % Total n-3 FA % 30.5 42.7 13.8 23.5 13.8 15.5 8.6 9.6 6.4 8.1 3.5 22.5 0.5 3.3 Spirulina: The Ultimate Food? • Cultured for over 600 years. • ~65-68% protein – (similar to herring) • One acre of this stuff produces 10 tons of protein (wheat only gets you 0.16 tons) Other Goodies… • Chlorella and Scenedesmus are also excellent sources of protein. • Could yield 40 tons/acre/yr • That would be feeding 1000 cows for a year with a one acre pond of this stuff 3 ft deep!! Spirulina is a single-celled, spiral-shaped blue-green microalgae. Highly digestible food, 60% vegetable protein, which is predigested by the algae. It is higher in protein than any other food. 1 tsp of Spirulina contains 280% DV Beta Carotene, 110% B12, 15% Iron, 2% Calcium and no fat. Its outstanding nutritional profile also includes the essential fatty acids, GLA fatty acid, lipids, the nucleic acids (RNA and DNA), B complex, vitamin C and E and phytochemicals, such as carotenoids, chlorophyll (blood purifier), and phycocyanin (a blue pigment), which is a protein that is known to inhibit cancer. The carotenoids and chlorophyll may also contribute to Spirulina's anticancer and apparent immunogenic effects. Spirulina is two to six times richer in B12 than its nearest rival, raw beef liver. Spirulina is 58 times richer than raw spinach in iron. Spirulina is nature's richest whole-food source of Vitamin E. It's 3 times richer than raw wheat germ and its biological activity is 49% greater than synthetic vitamin E. Spirulina is nature's richest whole-food source of Beta-Carotene (Pro Vitamin A). It's 25 times richer than raw carrots. Unlike the preformed vitamin A of synthetics and fish liver oils, beta-carotene is completely nontoxic even in mega doses. Spirulina is nature's richest whole-food source of Antioxidants. It contains a spectrum of every natural antioxidant known, including: the antioxidant vitamins B-1 and B-6; the minerals zinc, manganese and copper; the amino acid methionine; and the superantioxidants beta-carotene, vitamin E and trace element selenium. Spirulina is nature's richest whole-food source of Gamma Linolenic Acid (GLA). Its oils are 3 times richer in GLA than evening primrose oil. Studies have indicated that GLA helps lower blood cholesterol and high blood pressure and eases such conditions as arthritis, premenstrual pain, eczema and other skin conditions. Spirulina is nature's richest whole-food source of Chlorophyll - many times richer than alfalfa or wheat grass! Spirulina is nature's richest whole-food source of Complete High-Biological Value Protein: Spirulina - 60-70% Soybeans - 30-35% Beef - 18-22% Eggs - 12-16% Tofu - 8% Milk - 3% Phytoplankton Production • Feeding Larvae – Cell Size 4-8 microns – Species • Isochrysis galbana • Chaetoceros gracilis • Nannochloris sp. • Chlorella sp. • Pavlova lutheri Pavlova lutheri • Morphology – Golden brown – Spherical with 2 flagella – 3-6 µm • Salinity – 8-32 ppt • Temperature – 11-26 °C • Culture media – Guillards f/2 • Proximate Analysis – 52% Protein – 24% Carbs – 29% Fat Isochrysis galbana • Morphology – – – – • Tahiti (T-Iso strain) Golden brown Cells spherical with 2 flagella 5-6 µm length, 2-4 µm wide Salinity – 8-32 ppt • Temperature – 23 - 28°C • Culture media – Guillards f/2 • Proximate Analysis – 47% Protein – 24% Carbs – 17% Fat Chaetoceros gracilis • Morphology – Golden brown diatom – Medium-size 12 µm wide, 10.5 µm long – Cells united in chains • Salinity – 26 - 32 ppt • Temperature – 28 - 30°C • Culture media – Guillards f/2 with Si • Proximate Analysis – 28% Protein – 23% Carbs – 9% Fat Plankton for Larger Fry/Shellfish • Broodstock and Spat – Cell Size 10-24 microns – Species • Tetraselmis sp. – Green • Thalassiosra sp. – Diatom Tetraselmis sp. • Morphology – Ovoid green cells – 14 to 23 µm L X 8 µm W – 4 flagella • Salinity – 28-36 ppt • Temperature – 22-26°C • Culture media – Guillards f/2 • Proximate Analysis – 55% Protein – 18% Carbs – 14% Fat Thalassiosra sp. • Morphology – – – – – • Golden brown diatom Cells united in chains Barrel-shaped Non-motile 4 µm Salinity – 26 – 32 ppt • Temperature – 22-29 °C • Culture media – Guillards f/2 with Si • Other characteristics Micro Algae Culture • • • • • • • • • General Conditions Culture Phases Culture Water Sterilization Nutrient Enrichment Inoculation Cell Counts Harvest and Feeding Stock Culture Table 2.2. A generalized set of conditions for culturing micro-algae (modified from Anonymous, 1991). Parameters Range Optima Temperature (°C) 16-27 18-24 Salinity (g.l-1) 12-40 20-24 Light intensity (lux) 1,000-10,000 (depends on volume and density) Photoperiod (light: dark, hours) pH 2,500-5,000 16:8 (minimum) 24:0 (maximum ) 7-9 8.2-8.7 Figure 2.3. Five growth phases of micro-algae cultures. Lag/Induction Phase • This phase, during which little increase in cell density occurs, is relatively long when an algal culture is transferred from a plate to liquid culture. • Cultures inoculated with exponentially growing algae have short lag phases, which can seriously reduce the time required for upscaling. • The lag in growth is attributed to the physiological adaptation of the cell metabolism to growth, such as the increase of the levels of enzymes and metabolites involved in cell division and carbon fixation. Exponential Phase • Cell density increases as a function of time t according to a logarithmic function: C t = C0 x emt • Ct and C0 being the cell concentrations at time t and 0, respectively. • m = specific growth rate. The specific growth rate is mainly dependent on algal species, light intensity and temperature. • Phase of declining growth rate Cell division slows down when nutrients, light, pH, carbon dioxide or other physical and chemical factors begin to limit growth. • Stationary phase In the fourth stage the limiting factor and the growth rate are balanced, which results in a relatively constant cell density. • Death or “crash” phase During the final stage, water quality deteriorates and nutrients are depleted to a level incapable of sustaining growth. Cell density decreases rapidly and the culture eventually collapses. Why Did My Culture Crash?? • A better question might be why did it not crash? • Culture crashes causes: Nutrient depletion Overheating All of the above Oxygen deficiency pH disturbance (Those we didn’t mention.) • The key to the success of algal production is maintaining all cultures in the exponential phase of growth. • Moreoever, the nutritional value of the produced algae is inferior once the culture is beyond phase 3 due to reduced digestibility, deficient composition, and possible production of toxic metabolites. Culture Water Bad? • Sources – Seawater – Saltwater wells – Prepared seawater • Salinity – 26-32 ppt Nutrient Enrichment Not Right? Nutrients NaNO3 • Conc. (mg/l Seawater) 75 NaH2PO4.H2O 5 Na2SiO3.9H2O 30 Na2C10H14O8N2.H2O (Na2EDTA) 4.36 CoCl2.6H2O 0.01 CuSO4.5H2O 0.01 FeCl3.6H2O 3.15 MnCl2.4H2O 0.18 Na2MoO4.2H2O 0.006 ZnSO4.7H2O 0.022 Thiamin HCl 0.1 Biotin 0.0005 B12 0.0005 Guillard’s f/2 – Part A and B – 0.5 ml/L each part – Na2Si03 for diatoms Sterilization Techniques Poor? • Methods – Heat Pasteurization • 80 C and cool naturally – Autoclave – Sodium Hypochlorite (bleach) • 0.5 ml/L (10 drops) • Neutralize: 10-15 ml sodium thiosulfate (248 g/L) per liter – Hydrochloric acid (muriatic) • 0.2 ml/L (4 drops) • Neutralize: Na2CO3 0.4-0.9 g/L Figure 2.5. Aeration filter (Fox, 1983) Culture Types • Indoor/Outdoor. Indoor culture allows control over illumination, temperature, nutrient level, contamination with predators and competing algae, whereas outdoor algal systems make it very difficult to grow specific algal cultures for extended periods. • Open/Closed. Open cultures such as uncovered ponds and tanks (indoors or outdoors) are more readily contaminated than closed culture vessels such as tubes, flasks, carboys, bags, etc. • Axenic (=sterile)/Xenic. Axenic cultures are free of any foreign organisms such as bacteria and require a strict sterilization of all glassware, culture media and vessels to avoid contamination. The latter makes it impractical for commercial operations. Table 2.6. Advantages and disadvantages of various algal culture techniques. Culture type Advantages Disadvantages Indoors A high degree of control (predictable) Expensive Outdoors Cheaper Little control (less predictable) Closed Contamination less likely Expensive Open Cheaper Contamination more likely Axenic Predictable, less prone to crashes Expensive, difficult Non-axenic Cheaper, less difficult More prone to crashes Continuous Efficient, provides a consistent supply of high-quality cells, automation, highest rate of production over extended periods Difficult, usually only possible to culture small quantities, complex, equipment expenses may be high Semi-continuous Easier, somewhat efficient Sporadic quality, less reliable Batch Easiest, most reliable Least efficient, quality may be inconsistent Batch Culture • The batch culture consists of a single inoculation of cells into a container of fertilized seawater followed by a growing period of several days and finally harvesting when the algal population reaches its maximum or near-maximum density. • In practice, algae are transferred to larger culture volumes prior to reaching the stationary phase and the larger culture volumes are then brought to a maximum density and harvested. • Your handout depicts an example of how consecutive stages might be utilized: test tubes, 2 l flasks, 5 and 20 l carboys, 160 l cylinders, 500 l indoor tanks, 5,000 l to 25,000 l outdoor tanks (Figs. 2.6., 2.7). Inoculation • Culture vessels – 1,000 ml flask – 18.7 L (5 gal.) Carboy (glass) – 178 L (47 gal) Transparent Tank • Add enough algae to give a strong tint to the water – 100,000-200,000/ml • Lighting – Types • • • • Sunlight Fluorescent VHO fluorescent Metal halide – Highest Densities: 24/7 Figure 2.8. Carboy culture apparatus (Fox, 1983). Continuous Culture • The continuous culture method (supplied with fertilized seawater continuously, the excess culture is simultaneously washed out) • Permits the maintenance of cultures very close to the maximum growth rate! Very desireable. Turbidostat culture: Algal concentration (cell density) is kept at a preset level by diluting the culture with fresh medium by means of an automatic system. Chemostat culture: Fresh medium is introduced into the culture at a steady, predetermined rate. Addition of a limiting vital nutrient (e.g. nitrate) at a fixed rate is also required. This way the growth rate and not the cell density is kept constant. Cell Counts • Peak Algae Density – I. Galbana • 10-12 million cells/ml • 10-14 days • 2 wk stability – T. pseudonana • Hemacytometer – Count total in centermost 1 mm – Multiply by 10,000 – Product = number/ml • 4 million cells/ml • 3 days • 5 day stability Motile cells should be killed Harvest and Feeding to Fry • Algae Density • Larvae Density – 5-10 larvae/ml – Wk 1 = 50,000 cells/ml – Wk 2+ = 100,000 cells/ml – Onset of spatting = 200,000/ml • Tank cleared in 24hrs Liters to feed = (TD x V)/CD TD = Target Density (1,000s/ml) V = Volume of larval tank (thousands of L) CD = Cell Density (millions/ml) Harvesting and Feeding • Batch – Total harvest occurs once or over several days • Semi-Continuous – Works well with diatoms – Part of the algae remains in the vessel – New media is added to replenish the algae removed Stock Culture • Purchase pure strain • Avoid contamination – No aeration – Half filed container – Redundancy • Holding – Test tubes – Conical flasks • Transfer – 1 drop/wk for T. pseudonana – 1 drop/2 wk for I. galbana Production cost (US$.kg-1 dry weight) Remarks Source 300 Tetraselmis suecica 200 l batch culture calculated from Helm et al. (1979) 167 various diatoms continuous flow cultures (240 m3)a calculated from Walsh et al. (1987) 4-20 outdoor culture De Pauw and Persoone (1988) 160-200 indoor culture 23-115 summer-winter production continuous flow cultures in bags (8 m3) and tanks (150 m3)a Dravers (pers. comm. 1990) 50 tank culture (450 m3)a Donaldson (1991) 50 - 400 international survey among bivalve hatchery operators in 1991 Coutteau and Sorgeloos (1992)