Fundamentals of Operations Management 4e

advertisement

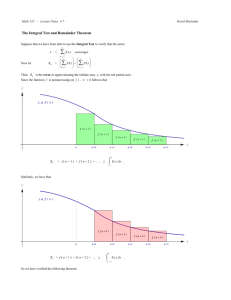

DAVIS F O U R T H E D I T I O N AQUILANO CHASE supplement 10 Work Performance Measurement © The McGraw-Hill Companies, Inc., 2003 PowerPoint Presentation by Charlie Cook Supplement Objectives • Introduce the more common types of work methods that are practiced in the workplace. • Understand the fundamental issues involved in developing work measurements. • Identify the basic elements associated with conducting a time study. • Determine how to design a work sampling study and apply it to an actual operation. Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–2 Work Methods • Studying the production system to: –Identify non-valued-added time delays, transport distances, process and processing time requirements –Simplify the entire operation by eliminating any step that does not add value to the product. Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–3 Work Methods and Design Aids Exhibit S10.1 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–4 Flow Diagram and Process Chart of an Office Procedure—Present Method* *Requisition is written by supervisor, typed by secretary, approved by superintendent, and approved by purchasing agent; then order is prepared by a stenographer. Source: Ralph M. Barnes, Motion and Time Study, 8th ed. (New York: John Wiley & Sons, 1980), pp. 76–79. Reprinted by permission of John Wiley & Sons, Inc. Fundamentals of Operations Management 4e Exhibit S10.2a © The McGraw-Hill Companies, Inc., 2003 S10–5 Flow Diagram and Process Chart of an Office Procedure —Present Method* *Requisition is written by supervisor, typed by secretary, approved by superintendent, and approved by purchasing agent; then order is prepared by a stenographer. Source: Ralph M. Barnes, Motion and Time Study, 8th ed. (New York: John Wiley & Sons, 1980), pp. 76–79. Reprinted by permission of John Wiley & Sons, Inc. Exhibit S10.2b Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–6 Common Notation in Process Charting Exhibit S10.3 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–7 Gilbreth’s Principles of Motion Economy Source: Frank C. Barnes, “Principles of Motion Economy: Revisited, Reviewed, and Restored,” Proceedings of the Southern Management Association Annual Meeting, Atlanta, GA, 1983, p. 298. Fundamentals of Operations Management 4e Exhibit S10.4a © The McGraw-Hill Companies, Inc., 2003 S10–8 Gilbreth’s Principles of Motion Economy (cont’d) Source: Frank C. Barnes, “Principles of Motion Economy: Revisited, Reviewed, and Restored,” Proceedings of the Southern Management Association Annual Meeting, Atlanta, GA, 1983, p. 298. Fundamentals of Operations Management 4e Exhibit S10.4b © The McGraw-Hill Companies, Inc., 2003 S10–9 WorkerMachine Chart for a Gourmet Coffee House Exhibit S10.5a Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–10 Worker-Machine Chart for a Gourmet Coffee House (cont’d) The customer, the clerk, and the coffee grinder (machine) are involved in this operation. It required 1 minute and 10 seconds for the customer to purchase a pound of coffee in this particular store. During this time the customer spent 22 seconds, or 31% of the time giving the clerk his order. He was idle during the remaining 69% of the time. The clerk worked 49 seconds, or 30% of the time. The machine was in operation 21 seconds, or 30% of the time. Exhibit S10.5b Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–11 Activity Chart of an Emergency Tracheotomy Source: Data taken from Harold E. Smalley and John Freeman, Hospital Industrial Engineering (New York: Reinhold, 1966), p. 490. Exhibit S10.6 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–12 Work Measurement • Work Measurement –The methodology used for establishing time standards. • Basic Industrial Engineering Methods –Time study –Elemental standard time data –Predetermined motion-time data –Work sampling Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–13 Types of Work Measurement Applied to Different Tasks Exhibit S10.7 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–14 Time Study • Time Study –The determination, with the use of a stopwatch, of how long it takes to complete a task or set of tasks. –Normal time = Observed performance time per unit x Performance rating –Piece rate is the rate paid for work completed. –Break down tasks by: • Defining each work element. • Separating human work from machine work. • Defining operator and machine delays separately. Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–15 Elemental Standard-Time Data • Time Standard –The established time for completing a job, used in determining labor costs associated with making a product. –Steps • Breakdown the new job into its elements • Match elements to the time for similar job-specific elements in the elemental table. • Adjust elements for special characteristics of the new job. • Add element times together and add delay and fatigue allowances. Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–16 Predetermined Motion-Time Data • Predetermined Motion-Time Tables –Create a time standard for a job or task based on standard times for basic motions (therbligs). –Can be applied to a wide-variety of tasks. Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–17 Work Sampling • Work Sampling –A statistical technique for estimating how workers allocate their time among various activities throughout a workday. –Issues involved: • What level of statistical confidence is desired in the results? • How many observations are necessary? • When should the observations be made? Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–18 Work Sampling (cont’d) • Determining the Required Number of Samples: 2 N Z p(1 p) E2 N = Number of observations to be made Z = Number of standard deviations associated with a given confidence level p = Estimated proportion of time that the activity being measured occurs E = Absolute error that is desired Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–19 Work Sampling (cont’d) • Steps in Conducting a Work Sampling Study: –Identify the activities for study. –Estimate the proportion of time of the activity of interest to the total time. –State the desired accuracy in the study results. –Determine the specific time when each observation is to be made. –If using an estimated time, recompute the required samples size at intervals during the study and adjust the number of observations. Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–20 Assignment of Numbers to Corresponding Minutes Exhibit S10.8 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–21 Determination of Observation Times Exhibit S10.9 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–22 Observation Schedule Exhibit S10.10 Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–23 Financial Incentive Plans • Basic Compensation Systems –Hourly pay –Straight salary –Piece rate –Commissions • Individual or Small-Group Plans • Organizational Plans –Profit sharing –Gainsharing Fundamentals of Operations Management 4e © The McGraw-Hill Companies, Inc., 2003 S10–24