ppt

advertisement

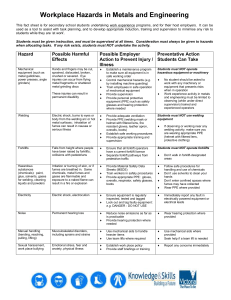

Tech Connect Welding General Welding Safety Practices Types of Welding Hazards Radiation exposure •Can cause retinal burning and cataracts •Proper lenses with the appropriate shading must always be worn •UV radiation cannot be sensed by heat or brightness Types of Welding Hazards (continued) Electric shock •Two kinds of electric shock: primary voltage shock and secondary voltage shock •Primary voltage shock involves 230 or 460 volts and is caused by touching both the lead inside the welding equipment and the welding equipment case or other grounded metal while the equipment is powered ON Types of Welding Hazards (continued) Electric shock (continued) •Secondary voltage shock involves 60 to 100 watts and is caused by touching a part of the electrode circuit and the side of the welding circuit. Types of Welding Hazards (continued) Electric shock (continued) •Do the following to avoid electric shock: ➤ Keep dry and wear dry gloves. ➤ Stand or lie on plywood, rubber mats or other insulation. ➤ Do not rest any part of the body on the workpiece. ➤ Keep electrodes and electrode holders in good condition. ➤ Do not touch electrodes or metal parts with either the skin or wet clothing. Types of Welding Hazards (continued) Fires and explosions •The welding process can produce extreme heat; however, fire hazards are not caused by the heat but by the effect of the heat on the workpiece, such as sparks and molten metal. •Keep the work area and all surrounding areas free of combustible items. •Be cautious when working in dusty areas where sparks and dust particles can easily oxidize without warning, which can result in a flash fire or an explosion. Types of Welding Hazards (continued) Fires and explosions (continued) •Do the following to protect from fire and explosions: ➤ Always know where the fire exits and fire extinguishers are located. ➤ If welding within 35 feet of a combustible object, utilize a fire watcher, who can watch for landing sparks. Gas Welding Safety from SafetyInstruction.com YouTube Types of Welding Hazards (continued) Fumes and gases •Fumes contain particles from base metal and base metal coating •Effects from fumes are normally temporary •Symptoms caused by short-term exposure to fumes can include burning eyes, burning skin, dizziness, nausea, and fever. •Long-term exposure to fumes can cause siderosis (which are iron deposits in the lungs) and can affect pulmonary function. Types of Welding Hazards (continued) Fumes and gases (continued) •Zinc fumes can cause metal fume fever, which is a temporary illness similar to the flu. •Cadmium fumes can cause symptoms similar to metal fume fever; however, it can be fatal, even under brief exposure •When shielding gases are released into the air, they can cause dizziness, unconsciousness, and even death if clean oxygen is withheld for a long enough period. Types of Welding Hazards (continued) Fumes and gases (continued) •UV radiation forms gases when it hits the air, which can cause headaches, chest pains, eye irritation, and itchiness in the nose and throat. Types of Welding Hazards (continued) Fumes and gases (continued) •Do the following to protect from fume and gas exposure: ➤ Ensure adequate ventilation in the work area. ➤ Wear appropriate personal protective equipment, such as a respirator. ➤ Read material safety data sheets before beginning work to learn what fumes can be potentially released. ➤ Familiarize yourself with the metals that are being used to determine if a paint or coating can cause toxic fumes or gases. Types of Welding Hazards (continued) Fumes and gases (continued) •Do the following to protect from fume and gas exposure: ➤ If symptoms of dizziness, headache, or nausea occur, turn off the welding equipment, notify supervisors and coworkers, and get fresh air immediately. Types of Welding Hazards (continued) Confined spaces •Examples of confined spaces include a boiler, tank, or hold of a ship where all the welding hazards are amplified, such as insufficient ventilation, fume and gas exposure, and chances of fire or explosion. Types of Welding Hazards (continued) Confined spaces (continued) •Do the following to protect yourself when working in confined spaces: ➤ Make sure your body is insulated from the workpiece and ground. ➤ Wear dry gloves. ➤ Use only a well-insulated electrode holder. ➤ Verify that there is sufficient ventilation. ➤ Always make sure there is a trained person outside the confined space at all times to disconnect power and pull the welder out if a dangerous situation occurs. Types of Welding Hazards (continued) Loud noise •Can cause temporary or permanent hearing loss •Do the following to protect against noise: ➤ Reduce the sound level when possible. ➤ Wear ear muffs or ear plugs. General Shop Safety Rules •Follow the rules. •Stay alert. •Properly use all tools and other materials •Respond immediately and appropriately to all safety-related incidents. •Wear appropriate clothing. Appropriate Clothing and Personal Protective Equipment ATI Professional Welding Section 1 Protective Clothing - YouTube •Shirts—Wear heavy, long-sleeved shirts with pocket flaps; remove pockets or tape them shut if they do not have pocket flaps; keep collar and sleeves buttoned to keep out sparks. Clothing Appropriate Clothing and Personal Protective Equipment (continued) •Pants—Wear pants that have no cuffs and are long enough to cover the top of your shoes or boots. •Welding cap—Wear a cap with a flexible bill that can be slipped around to cover either ear to keep sparks and metal splatter out of the ear opening. Appropriate Clothing and Personal Protective Equipment (continued) •Boots—Wear steel-toed boots made of heavy leather with uppers that reach above the ankle. •Gloves—Wear heavy leather gloves with gauntlets; gauntlets may be short or extend to the shoulder. Appropriate Clothing and Personal Protective Equipment (continued) •Jackets and aprons—Wear leather jackets and aprons for additional protection, especially when welding in confined areas. Appropriate Clothing and Personal Protective Equipment (continued) Eye protection •Safety glasses—Wear at all times in the welding area; include side protection when flying objects are possible. Appropriate Clothing and Personal Protective Equipment (continued) •Face shield—Wear a face shield, along with safety glasses, when grinding, chipping, cutting, or shaping metal with any type of power tool. Appropriate Clothing and Personal Protective Equipment (continued) •If you wear contact lenses, check with your doctor to see if the type of lens you wear requires any special precautions in the work area. •If your wear prescription lenses, either wear eye protection that incorporates that prescription into the lens or appropriate eye protection that can be worn over your existing lenses. •Select the appropriate lens shade when wearing safety glasses, goggles, or a welding hood. Appropriate Clothing and Personal Protective Equipment (continued) Welding hoods •Stationary filter lens—Contains a fixed lens housing with the shaded lens held in by a spring retainer from where a lens can be slipped out and replaced as welding requires. Appropriate Clothing and Personal Protective Equipment (continued) Welding hoods •Flip-front filter lens—Contains a lens housing with a front side that can be flipped up so that it leaves a clear-glass lens that permits the hood to be worn while chipping. Appropriate Clothing and Personal Protective Equipment (continued) Welding hoods •Auto darkening lens—Used in helmets specifically designed for auto darkening lenses; contains sensors that automatically change the shade from clear to dark in a fraction of a second when you start to weld and gradually changes back to clear when you stop welding; can be manually adjusted for a variety of shades. Hazards Caused by Fumes and Gases Hazards Caused by Fumes and Gases (continued) Hazards Caused by Fumes and Gases (continued) Hazards Caused by Fumes and Gases (continued) Hazards Caused by Fumes and Gases (continued) Information Included on a Material Safety Data Sheet (MSDS) •Chemical Identity •Hazardous Ingredients •Physical and Chemical Characteristics •Fire and Explosion Hazard Data •Reactivity Data •Health Hazard Data •Precautions for Safe Handling and Use •Control Measures Common Safety Signs Common Safety Signs (continued) Fire Extinguisher Ratings •Class A – Ordinary combustibles like wood, paper and cloth •Class B – Flammable liquids like grease, gasoline, paints and oil Fire Extinguisher Ratings (continued) •Class C – Energized electrical equipment like motors, switches, and computers •Class D – Combustible metals like titanium, sodium, and magnesium Fire Extinguisher Ratings (continued) •Class K – Oils or fats used with cooking appliances First Aid Procedures for Various Emergency Situations Cuts •Stop the bleeding by applying gentle, continuous pressure with a clean cloth or bandage. •Clean the wound with clear water. •Apply an antibiotic to the wound to keep it moist. •Cover the wound with a bandage to keep it clean and protected. First Aid Procedures for Various Emergency Situations (continued) Cuts (continued) •Change the dressing at least once a day or when it becomes wet or dirty. •Get stitches for deep wounds. •Be alert to signs of infection. •Get a tetanus shot within 48 hours if your wound is severely dirty, more than five years have passed since your last tetanus shot, and it is recommended by your physician. First Aid Procedures for Various Emergency Situations (continued) Burns •Determine the type of burn. •Apply appropriate treatment. Chemicals in the eye •Use clean, lukewarm water to flush the eye for at least 20 minutes. •Thoroughly wash the hands with soap and water. First Aid Procedures for Various Emergency Situations (continued) Chemicals in the eye (continued) •Remove contact lenses if they do not fall out while flushing the eye with water. •Seek medical assistance if necessary. First Aid Procedures for Various Emergency Situations (continued) Traumatic shock •Identify the symptoms of traumatic shock: ➤ Early stages ➤ Late stages •Lay the victim down. •Elevate the legs slightly. •Cover the body with a blanket to prevent loss of heat. First Aid Procedures for Various Emergency Situations (continued) Electrical accident •Do not provide any medical aid until the electrical current has been shut off. •Administer CPR if necessary, and you have the proper training. •Treat for traumatic shock and electrical burns. First Aid Procedures for Various Emergency Situations (continued) Choking •Recognize the signs of choking. •Perform the Heimlich maneuver. First Aid Procedures for Various Emergency Situations (continued) Head injury •Keep the person still and lying down, with the head and shoulders slightly elevated. •Do not move the person unless necessary. •Apply light pressure with a sterile gauze to stop any bleeding. •If the person stops breathing, perform CPR if you are properly trained. First Aid Procedures for Various Emergency Situations (continued) Head injury •Keep the person still and lying down, with the head and shoulders slightly elevated. •Do not move the person unless necessary. •Apply light pressure with a sterile gauze to stop any bleeding. •If the person stops breathing, perform CPR if you are properly trained. First Aid Procedures for Various Emergency Situations (continued) Heat exhaustion •Recognize the symptoms: ➤ Extreme perspiration ➤ Pale, clammy skin ➤ Rapid, weak pulse ➤ Rapid shallow breathing •Immediately move the victim to a cool place. •Lay victim flat and elevate the feet slightly. First Aid Procedures for Various Emergency Situations (continued) Heat exhaustion (continued) •Remove as much of the victim’s clothing as possible. •Sponge the skin with cool water. Guidelines for Proper Lifting •Check the box or item for nails, splinters, rough areas, grease, or slippery surfaces. •Wear appropriate personal protective equipment. •Plan your route before you lift •Check your path of travel and remove any obstructions from your path. Guidelines for Proper Lifting •Make sure you can handle the weight of the load by yourself before trying to lift it. •Place your feet close to the object and about shoulder-width apart. •Bend your knees and grip the object securely. •Using your leg muscles, push up with your legs, keeping your back straight. Guidelines for Proper Lifting (continued) •Keep the load close to your body as you travel. •Turn your feet to turn your body. •Lower the load by bending your knees, again making sure to keep your back straight. •Carefully set the load down, being careful to watch your fingers. Proper Use of a Ladder Inspect the ladder before each use •Verify that the ladder has no defects. •Verify that the steps or rungs are clean and not damaged. Proper Use of a Ladder (continued) Properly set up the ladder •Follow the one-to-four ratio rule for extension ladders. •Verify the ladder is standing on firm, dry ground. •Verify that an extension ladder is leaning against a solid structure. •Fasten an extension ladder to the structure it is leaning against when accessing high places. Proper Use of a Ladder (continued) Properly set up the ladder (continued) •Verify that a stepladder is fully open and the divider locked. •Place the top of extension or straight ladders at least three rungs above the work. •If using a ladder in front of a door, lock the door before ascending the ladder. •Set up a ladder as far away as possible from electrical lines. Proper Use of a Ladder (continued) Properly set up the ladder (continued) •Verify that a stepladder is fully open and the divider locked. •Place the top of extension or straight ladders at least three rungs above the work. •If using a ladder in front of a door, lock the door before ascending the ladder. •Set up a ladder as far away as possible from electrical lines. Proper Use of a Ladder (continued) Be cautious to avoid accidents •Do not climb higher than the third rung on extension ladders or second tread from the top of stepladders. •When working with both hands, lock one leg around a rung. •Do not overreach. •Keep your belt buckle between the rails. •Do not put one foot on the ladder and the other on an adjacent surface. Proper Use of a Ladder (continued) Be cautious to avoid accidents (continued) •Never stand on the braces, extension arms, or paint shelf. •Use a ladder only for the purpose of reaching places you can not reach from the ground. •Do not work in windy conditions. •Do not leave a ladder unattended. Lockout/Tagout Policy Locking •Obtain permission from a supervisor before you plan to lockout a piece of equipment. •Shut off the equipment. •Place the locks on the switches and valves. •Try to start the equipment or open the valves. •Begin working. •When the work is completed, verify that all employees are cleared of the equipment before removing the locks and tags. Lockout/Tagout Policy (continued) Tagging •Write a brief message on the tag, if necessary. •Write your name and the date. •Attach the tag in a visible location. © 2008 Oklahoma Department of Career and Technology Education