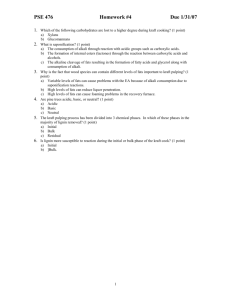

Lecture 2: Mechanical Pulping

advertisement

Pulping and Bleaching PSE 476 Lecture #2 Mechanical Pulping Agenda • Mechanical pulping » » » » » Grinding-logs Refining-chips Mechanical pulp properties Process conditions (chemicals, steam, etc.) Canadian Standard Freeness Test Mechanical Pulping • Mechanical pulping is the process by which fibers are produced through mechanical methods: • Grinding-Stone Groundwood (SGW) » Logs (very occasionally chips) are pressed into a turning stone thus releasing fibers. • Refining-Refiner Pulp » Chips are fed between 2 disks. One disk is always turning while the other can be fixed or turning. » Often heat or a chemical pretreatment is utilized. Mechanical Pulping General Info • Raw Material Quality » Pulps cannot be brightened very much; therefore good quality material must be used - Chips used should be less than 2 weeks old (oxidation and biological decay darken chips after this point). - Low bark and dirt tolerance (color and machinery wear issues). • Species Dependence » Different wood species work better in different processes. Properties of Mechanical Pulp • Relatively cheap » High yield of product (85-95%) » Low capital costs relative to Kraft mill • High opacity product » Large amount of fines in product scatter light » Allows printing on both sides of thin sheet • Good printing surface » Broad fiber size distribution gives smooth surface » Good bulk Properties of Mechanical Pulp • Relatively weak product » Not strong enough to get through printing press » Need to add chemical fibers to product - Can use recycle fibers • Limited brightness » Bleached with lignin retaining bleaching agents • Photoyellowing » Formation of chromophores from lignin compounds through the reaction with light and oxygen Stone Groundwood: Equipment • Not used at all in the Pacific Northwest—all our wood leftovers from saw mills as chips. • Different designs. • Logs are pressed into a rotating stone. • The fibers are washed off the stone with water (cools the stone). - Running this system under a slight pressure improves the process. Mechanical Pulping Overview Stone Groundwood: Equipment • The surface of the stones are cut with patterns (burrs) using a metal burr. • Patterns are 1.6 mm deep. • The stones must be sharpened every 50-150 hours. Pulpstone “sharpening” • Sharpening= fracturing the softer bond posts. • This causes the worn grains to be removed, uncovering new sharp abrasive grains. • Why sharpen? » To expose fresh abrasive grit. » To control the compression / decompression frequency on the wood fibres. » To control fibre length. » To clean stone pores. » To carry water into the grinding zone and pulp out of the grinding zone. Mechanical Pulping Overview Stone Groundwood: Mechanism This is a poor reproduction of a drawing showing the action of the stone on the surface of the wood. Source: Handbook of Pulping and Papermaking , Biermann, C, 1996, page 65 Mechanical Pulping Overview Stone Groundwood: Mechanism • The burrs on the stone alternately compress and decompress the fibers. This loosens the fibers. Additionally, the heat developed softens the lignin in the middle lamella which helps the process. • The application of heat or chemical will also soften the lignin and improve this process. Mechanical Pulping Groundwood Flowsheet Logs Drum Washer There is a latency tank before bleaching which serves to Grinder Bull Screen Refiner Fine Screen Press Refiner Centrifugal Cleaner Thickener “uncurl” the fibers. Screen Bleaching Storage Paper Machine Refiner Pulping • Refiner Mechanical Pulping (RMP) • Thermo-mechanical Pulping (TMP) • Chemi-mechanical Pulping (CMP) • Chemi-thermomechanical Pulping (CTMP) • The differences between these systems are discussed in the notes section and on the next slide. Small laboratory refiner Notes Mechanical Pulping Process Conditions Process Temp (C) Chemicals pH RMP Heating Time (min) NA NA NA NA TMP 1-10 110-140 NA NA NA NA CTMP 1-10 110-140 2-5% Na2SO3 9-12 2-5 120-130 CMP - Cold NaOH NA NA NaOH Bath 12+ 120 30 - Sulfite 1-10 110-140 9-12 6 12 60 130-170 3 - 30 minute reactions Steamed SCMP/BCMP ARTMP 1-10 12-17% Na2SO3, 12-17% NaHSO3 110-140 0.65% DTPA, 0.05% Mg2SO4, 3.1% NaSiO3, 5.1% NaOH, 4.1% H2O2 Pretreatment Pretreatment Time Temp (min) (C) NA NA Refiner Plates • The refiners contain opposing plates that shred the chips. These plate are separated into different sections » 1st section (inlet) rips chips into wood slivers. » Each subsequent step reduces the size of the bundles. » Water carries the fibers through the disk. Refiner Plates (2) Directional Variable pitch Chicane Refiner Pulping Typical Refiner Flowsheet Oversize Chip Screen Fines Rechipper Chip Washer First Stage Refiner Reject Refiner Second Stage Refiner Screens Screens Centrifugal Cleaners Rejects Thickener Thickener Bleaching Storage Paper Machine Refiner Pulping CMP (CTMP) Process Chemicals • Hot Sulfite (NaOH + Na2SO3) » NaOH swells wood for easier refining. » Sulfite prevents the wood from darkening upon this treatment. • Cold Soda (NaOH) » NaOH swells the wood. » Some hemicelluloses and all resins lost. » Softwoods resist this treatment so used only for hardwoods; a very very minor process. Refiner Pulping CMP Process Chemicals • Alkaline Peroxide (NaOH + H2O2) » Pulping and bleaching together. » Difficult with Softwoods. » Need to stabilize peroxides against: - Thermal degradation and degradation by metals » Silicates used to stabilize peroxides can deposit on refining equipment. • CTMP (2-5% Na2SO3) » Most common of the chemical processes. The lignin is sulfonated to only a very slight extent. This softens the lignin making fiber removal easier. Mechanical Pulping Determination of Endpoint • In chemical pulping, the pulping reaction is allowed to go until a certain level of lignin is reached as determined through the determination of Kappa number. • In mechanical pulping, the material is refined until a specific freeness is reached. » Freeness is the ease with which water leaves the fiber mat formed on a wire mesh from a dilute slurry. Mechanical Pulping Overview Endpoint Determination • Canadian Standard Freeness » Measurement of ease at which water leaves a fiber mat » Simple, quick, reproducible but not always meaningful • High Freeness » 750 ml water: Unrefined chemical pulp • Low Freeness » 20 ml water: Heavily refined - mechanical pulp