Manufacturing Improvement, Inc.

advertisement

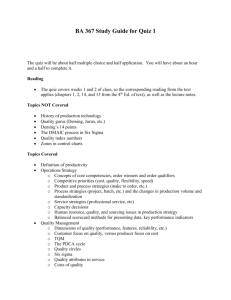

Continuous Improvement Bill Pedersen, PE There are 3 ways to get better numbers: • Distort the System – Downsizing example – Reduced inventory example • Distort the figures – End of Quarter Example • Improve the System!!!!!! Continuous Improvement isn’t just about improving, it is about improving an organization’s ability to improve. “Speed is everything. It is the indispensable ingredient in competitiveness.” • Jack Welch, GE CEO • There is always one basic goal. Any ideas what that might be? • SIMPLIFY!!!!!!!!!!!!!! • Start with the basic building blocks. • Improve on that. • Repeat - forever. Seven Step Procedure • Define the Opportunity • Study the Current Situation - Key measures, measurement system, R&R. • Cause Analysis - Pareto and Fishbone Diagrams, Run Charts, Control Charts. • Experiment with the Process - Cpk, EZs, DOE • Check Results - new Cpk. • Standardize - SOPs, TPDs. • Communicate the gain - Improvement Record. A Few Continuous Improvement Tools It isn’t the tools of improvement that are so important. It is the principles behind those tools that make the difference. Applications of Continuous Improvement • Product Redesign Example • Plant Operation and Scheduling Example • Machine Utilization Example LEADERSHIP! • Sir Ernest Shackleton • Johnsonville Sausage • Merck & Co., Inc. What is SPC? • My Definition: The use of statistical tools to promote continuous improvement and consistently produce high quality parts. • Management by Data Motivation for Using SPC • SPC is one of the most important continuous improvement tools. • Variation is the enemy. SPC allows you to identify and eliminate causes. • Gets people involved with process. • Provides hard numbers by which to judge performance. • Excellent source of statistical data to incorporate into designs. Data Types • Continuous Data - Time - Temperature - Dimensions • Use Continuous Data whenever possible more information. • Attribute Data - Go/No Go gage Pass/Fail Number of defects Above/Below Setpoint • As Quality improves, sample size increases dramatically. • Sample size such that n x p >= 5 Basis of SPC 68.26% 95.46% 99.73% Central Limit Theorem • Justification of assuming a normal distribution: – The averages of independently distributed random variables is approximately normal, regardless of the distributions of the individual samples. SPC System Tools • Many times SPC is thought of as control charts. They are only one component of SPC. • It it the continuous improvement system and methodology that makes this work. Variation • Common Causes of Variation – Are always present. – Several small contributors add up to the whole common cause variation. – Examples - weather, machine rigidity, incoming material variation. • Special Causes of Variation – NOT always present sporadic in nature. – Typically have a larger effect on variation than any single common cause. – Examples - broken air conditioner, worn bearing, incorrect material. Sources of Variation - 5 M’s • • • • Machines Method Man Materials (Incorporates environment usually) • Measurement Measurement System • Must verify the measurement system is precise and accurate. Precise Accurate Repeatability and Reproducibility or Gage Capability • VarianceTotal = Varianceproduct + Variancemeasurement • Variancemeasurement = Variancerepeatability + Variancereproducibility • Repeatability - Can the same operator get consistent results? • Reproducibility - Can two operators get the same results? Bad Application of a good tool Control Charts • Many Types, the most common– – – – – – – Xbar and R, average and range Xbar and mR, average and moving range Xbar and S, average and variation of sample p chart, proportion defective np chart, number of defects/sample c chart, number of defectives/sample u chart, u=c/n => average defects/unit Primary Goal of Control Charts Elimination of Variation Primary Problem with Control Charts Charting for the Sake of Charting Control Limits • Control limits are generally set at +/- 3 sigma from the mean, (both estimated from samples) • example - xBar, R chart – UCL = Xdoublebar + A2*R – LCL = Xdoublebar - A2*R • Central Limit Theorem - The averages of independently distributed random variables is approximately normal, regardless of the distributions of the individual samples. Out of Control Conditions • A process that is in control only has common cause variation present. • An out of control process has special cause variation present as well. • Common cause variation is random in nature. If there is a pattern present, it is assumed to be due to a special cause. Out of Control Conditions - ctd 1. Zone C Zone B Zone A • Any point outside of Outcontrol of Controllimits. Examples • Eight points in a row on one side of centerline. 4. 5. 6. 2. 3. • Seven points in a row steadily increasing or decreasing. Zone A • Fourteen points in a row alternating up and down. Zone B • Two of Three in a row outside of 2 sigma, (same side of Zone C centerline). • Four of Five in a row outside of 1 sigma, (same side of centerline). • NOTE: You will see variations in these rules. The difference is based on statistical confidence desired. Xbar, R chart example - ctd • Sample sizes determined to be subgroups of three, with sampling frequency every order. – Will hopefully be able to reduce this later on. • Need to determine control limits. – Set up a run chart to gather data. – After 25 samples, use that to calculate control limits. • Xdoublebar +/- A2*R • Range Chart: – UCL = D4*Rbar – Centerline = Rbar – LCL = D3*Rbar Title/Process Description: Variables Chart Tail PartBend Length Height Date Formulas: Model X = ( x1+x2+x3 ) / 3 Size Data 1 2 3 AVG. (X) Target Deviation Range D = X - Target Range = Greatest Data Least 1 RANGE (R) AVERAGE (X) 0.024 NOTES 0.014 Plotted Limits UCL 0.016 0.004 -0.006 -0.016 0.030 -0.026 0.025 0.014 0.020 0.012 0.015 0.010 0.010 0.008 0.005 0.006 0.000 0.004 0.002 0.000 X 0.000 LCL -0.016 UCL 0.011 R 0.004 Xbar, R chart example - ctd • Action plan for out of control conditions is well documented and operators have been trained. • Try it and see what happens. • After you fix the bugs, then try it again. • Be sure to check the chart personally every shift, (multiple times at first). Take action when necessary. This is extremely important to the operators, not to mention the process. What to do with all this data? • Impress your friends. • Pareto - 80/20 rule. Work on the most significant special cause. Pareto of Causes 100% 80% 15 60% 10 40% 5 20% 0 0% Improper Fixturing Worn Tool Worn Bit Defects Material Defect Slippage Percentage Number 20 Overadjustment • This is usually the result of a lack of understanding that variation is random in nature. • Perfect example - Budgets. – Spend it or lose it. – Matching next years budget to this years spending. – Result is a steadily increasing trend away from centerline. The rich get richer, the poor get poorer. Capability Index - Cpk • Control charts have control limits. What were they based on? – The actual variation from the process. • Specification limits determine which product is acceptable. They have nothing to do with the control limits whatsoever. • Cpk is used to predict the percentage out of specification based on the estimated process average and variation. Cpk - ctd Z-distribution Defects vs. Cpk (centered) 100000 16395 - centerline)/(UCL - centerline) • Cp = (USL 10000 log (Defects (ppm)) 2700 – 1000 or centerline minus lower limit. 318 • Cpk100= min(Cp) 63 27 10 • In other words if the Spec6.8Limits just 1.6 1 happened to be equal to the Control Limits, 1.80 then 0Cpk = 1.0 0 0.002 0 0.80 1.00 1.20 1.40 1.60 1.80 1.33 1.50 Cpk (centered) 2.00 2.20 Six Sigma • Cp = 2.0 • Cpk = 1.5 due to shifting of the process by 1.5 standard deviations over time. • Result - one sided distribution failure of 3.4 ppm. • Application - electronics. Improving a Process that is in Control • Design of Experiments. – – – – – Machine modifications. Method Changes, (SOPs). Material Changes. Manpower Changes, (training plan). Measurement changes are not generally advised, but don’t always rule it out, especially if the process has been running in control for quite some time. Seven Step Procedure - revisited • Define the Opportunity • Study the Current Situation - Key measures, measurement system, R&R. • Cause Analysis - Pareto and Fishbone Diagrams, Run Charts, Control Charts. • Experiment with the Process - Cpk, EZs, DOE • Check Results - new Cpk. • Standardize - SOPs, TPDs. • Communicate the gain - Improvement Record.