The actual measuring principle implemented by EMG SOLID ® is

Infrared online oil layer measurement with EMG SOLID

®

With the beginning of 2016 EMG will be offering the EMG SOLID ® measuring system

(Surface Oil Layer Inline Determination) as a third system for the online measurement of key product parameters for processing steel and aluminium strip material.

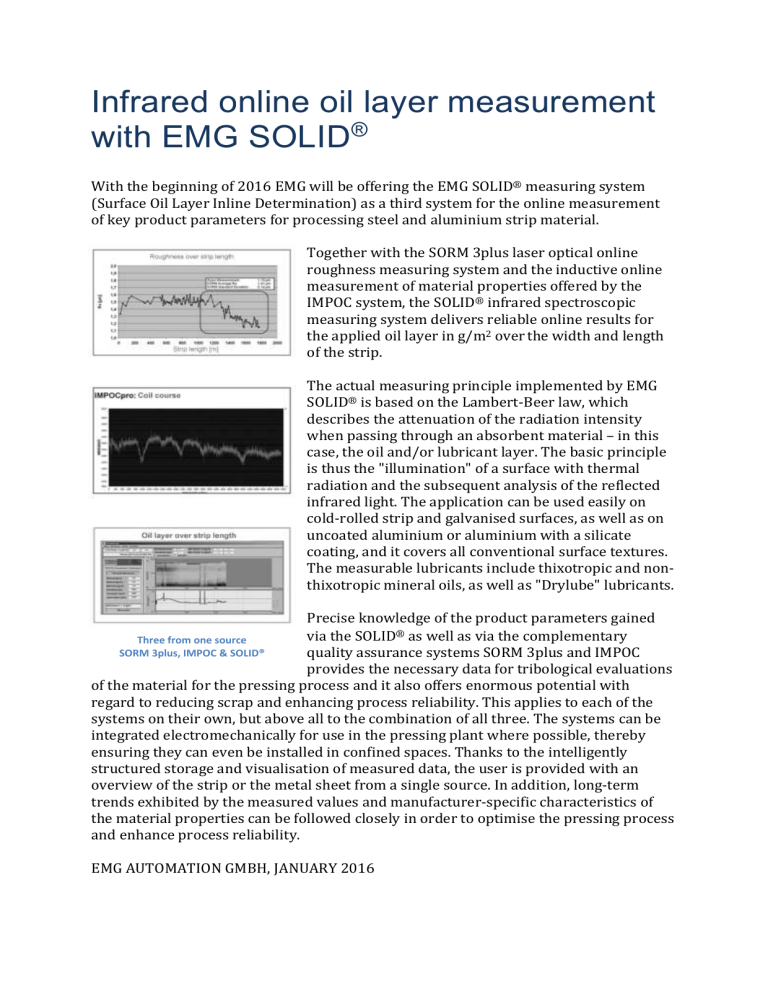

Together with the SORM 3plus laser optical online roughness measuring system and the inductive online measurement of material properties offered by the

IMPOC system, the SOLID ® infrared spectroscopic measuring system delivers reliable online results for the applied oil layer in g/m 2 over the width and length of the strip.

The actual measuring principle implemented by EMG

SOLID ® is based on the Lambert-Beer law, which

Three from one source

SORM 3plus, IMPOC & SOLID® describes the attenuation of the radiation intensity when passing through an absorbent material – in this case, the oil and/or lubricant layer. The basic principle is thus the "illumination" of a surface with thermal radiation and the subsequent analysis of the reflected infrared light. The application can be used easily on cold-rolled strip and galvanised surfaces, as well as on uncoated aluminium or aluminium with a silicate coating, and it covers all conventional surface textures.

The measurable lubricants include thixotropic and nonthixotropic mineral oils, as well as "Drylube" lubricants.

Precise knowledge of the product parameters gained via the SOLID ® as well as via the complementary quality assurance systems SORM 3plus and IMPOC provides the necessary data for tribological evaluations of the material for the pressing process and it also offers enormous potential with regard to reducing scrap and enhancing process reliability. This applies to each of the systems on their own, but above all to the combination of all three. The systems can be integrated electromechanically for use in the pressing plant where possible, thereby ensuring they can even be installed in confined spaces. Thanks to the intelligently structured storage and visualisation of measured data, the user is provided with an overview of the strip or the metal sheet from a single source. In addition, long-term trends exhibited by the measured values and manufacturer-specific characteristics of the material properties can be followed closely in order to optimise the pressing process and enhance process reliability.

EMG AUTOMATION GMBH, JANUARY 2016

Contact EMG Automation GmbH:

EMG Automation GmbH

Frau Nicol Otterbach

Industriestrasse 1

57482 Wenden

Germany

Telephone: +49 (0) 27 62 / 6 12-126

Telefax: +49 (0) 27 62 / 6 12-384

Email:Nicol.Otterbach@emg-automation.com

If you decide to print this article please send a copy to the above-listed press contact. We thank you in advance.

About EMG Automation

EMG Automation GmbH, a company of the elexis group, belongs to the leading suppliers, due to its technological competence in the core area of regulation systems as well as quality assurance in automated manufacturing processes. Fields of application are fast running continuous production processes in the metal and especially in the steel industry. The product portfolio includes, besides quality assurance systems, strip running regulators. The EMG group runs its own factories as well as sales and service offices in

Wenden/Germany, Oschersleben/Germany, Bielefeld/Germany, Rengsdorf/Germany, Elmhurst/USA, Belo

Horizonte/Brazil, Osaka/Japan, Baroda/India, Beijing/China, Shanghai/China as well as Madison/USA.