PHYSICS 225, 2ND YEAR LAB

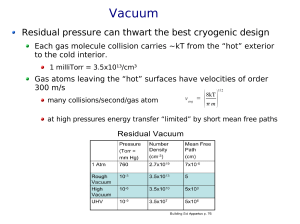

advertisement

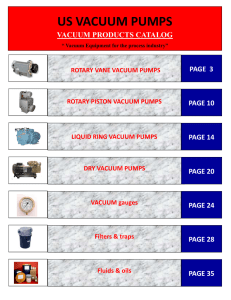

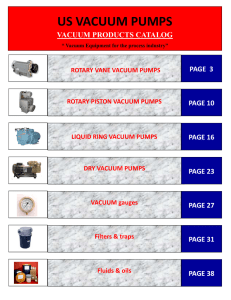

PHYSICS 225, 2ND YEAR LAB VACUUM TECHNOLOGY G.F. West Thurs, Jan. 12 INTRODUCTION Humans work in a gaseous environment. Although less dense than solids or liquids, the normal gas environment greatly influences much physics. Often, to do interesting and important physics, one must get rid of it. WHAT IS A VACUUM ? The absence of appreciable matter (i.e., atoms, molecules, ions, particles), usually as gas. How do we measure the amount of gas? As mechanical pressure on container walls or neighbouring gas. Pressure = Force /unit area = N/m2= Pa (SIU); = bars (cgs) = psi (USA/Imperial); = Atm (Chem); = mmHg = Torr (traditional physics); KINETIC THEORY OF GASSES (The colliding billiard ball model ) Gas atoms have a range of velocities, increasing with temperature. Gas molecules therefore have appreciable energy and momentum. Pressure is the cumulative result of the momentum changes in collisions. Collision likelihood is usually expressed as “mean free path” (average distance molecules move between collisions). LEVELS OF VACUUM Air at 273 K, molecular Vrms ~ 485 m/s Pressure (V HV UHV UHV ) Atm, 1.0 1/760 kPa, 101.3 0.13, 0.13Pa psi, 14.7 0.02 Torr, 760 1 1e-3 1e-6 1e-9 1e-12 Mean Free Path, at 273 K, mol radius 0.3 nm; m ~1e-7,~7e-5,~7e-2, ~7e+1,~7e+4, ~7e+7 VACUUM PUMPS Mechanical; with valves, vanes, diaphrams (Roughing pumps, forepumps). Entrainment principle Diffusion pumps, Turbomolecular pumps. Entrapment principle Cryopumps, ionpumps (gettering) TI sputtering molecular sieves (zeolites and other synthetic microporous compounds) PROBLEMS WITH PUMPING Need for a forepump. Contamination of vacuum by backflow. Gas selectivity. Need for regeneration. Virtual leaks. Speed, ease of cycling to lab conditions. VAPOUR PRESSURE MULTI-PUMP SYSTEM ROTARY VANE FORE PUMP DIFFUSION PUMPS TURBO-MOLECULAR PUMPS TURBOMOLECULAR PUMP Specifications MDP 5011 Pumping speed (L/s N2) Ultimate pressure (Torr) 7.5 7.5 x 10 -7 Compression ratio: 9 ......N2 1 x 10 ......He 2 x 10 ......H2 1 x 10 Speed (rpm) 27,000 Max. ambient temp (°C) Exhaust flange 4 3 50 QF16 Pump weight (lb) 5.5 Power supply (VAC) 115 Other voltages available on request ION PUMP ION VACUUM GAUGE THE VACUUM ENCLOSURE Materials: (Glass & stainless steel predominate.) Requirements: Chemically inert Cleanable Bakeable Strong Workable, (e.g., machineable) TYPICAL VACUUM SYSTEM Forepump Main vacuum pump with cooling. Gate valve,(to allow pump turn off). Vacuum gauges, if not intrinsic to pumps. Cold trap(s) (Liquid air). Sample inlets, if required. View & manipulation ports, experiment area. Bakeout system. VACUUM SYSTEM COMPONENTS Older systems mainly were hand fabricated from glass by artisanal glassblowing. New systems mainly are constructed from commercially manufactured stainless steel components using (e.g.,): Bolted flange connections Thin metal seals Glass- to-metal sealed electrical connections Bellows connected or in-vac bakeable manipulators Special window glasses for radiation entry/exit VACUUM COMPONENTS USES OF VACUUM TECHNOLOGY Some examples: Semiconductor lithography and surface coating. Analytical inst’s; e.g., spectrometers, microscopes. Particle accelerators, HEP Space simulation Nanotechnoloy Surface physics. Gas lasers. Manufacturing of special materials.