PowerPoint Template Guidelines

advertisement

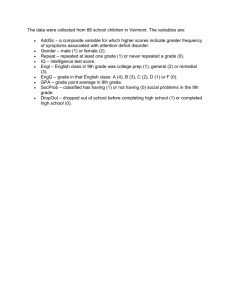

MARINE DIVISION – OVERSEAS SUPPLY ISSUES Paul Webb, Stewart Millar 22/03/2016 1 NucSIG Event – 9th June 2010 • Submarine 1st Level Quality Assurance PURPOSE To ensure that submarines are operated and maintained to the correct Standard and to the correct Specifications so that they are capable of achieving their design performance throughout their operational life. SCOPE Applicable in 3 main systems areas: Submarine Safety Reactor Safety Personnel Safety NucSIG Event – 9th June 2010 • High precision items of equipment such as Submarine 1st Level Items: – PUMPS – VALVES – ACTUATORS etc, etc. Are subjected to a high level of control throughout the design, manufacture, assembly, operation and overhaul phases. It becomes a real challenge to ensure the intended operation of the item meets the customers exacting requirements. NucSIG Event – 9th June 2010 • Even basic items can at times present a challenge! Example one being: A Weld Insert NucSIG Event – 9th June 2010 • What is a Weld Insert? NucSIG Event – 9th June 2010 • A Formed Insert - to form the root of a weld NucSIG Event – 9th June 2010 NucSIG Event – 9th June 2010 • Associated Problem – – – – – – Welding Issue Material Analysis Documentation Checks Wider concern and further checks Supply Chain Audit and Findings NucSIG Event – 9th June 2010 • Second example is something as basic as:- Locking Wire NucSIG Event – 9th June 2010 NucSIG Event – 9th June 2010 • Where is it used? – Inside the Steam Generator Purpose - to wirelock the fasteners which hold Chevrons and Driers etc NucSIG Event – 9th June 2010 • Associated Problem – – – – – – Material Shortcoming Material Analysis Documentation Checks Supply Chain Audit and Findings. Additional Issues NucSIG Event – 9th June 2010 NucSIG Event – 9th June 2010 • How might you procure steel tubing at short notice? Use a detailed QA Statement of Requirements? Use an ISO certificated steel stockist? Use a major UK stockist of steels, alloys & plastics? Use a local stockist we have approved? Use a stockist with a proven track record? NucSIG Event – 9th June 2010 • Our Purchase Order Specification demanded material certification for: Chemical, Mechanical, Heat Treatment, Ultrasonic, Surface Finish, Pressure & Dimensional • Demonstrates design intent maintained • Safety Case reliability targets not undermined NucSIG Event – 9th June 2010 But what if the certification reads? NucSIG Event – 9th June 2010 • • • • • • All examples are basic items All examples involved additional testing Some involved concession action One supplier no longer used Other given additional supply conditions Each example incurred extra costs • No budget for additional supply chain assurance Especially Overseas! NucSIG Event – 9th June 2010 Babcock Engineering Services Intec Devonport Management Ltd. Babcock International Group Marine Division Babcock Naval Services SSMG Strachan & Henshaw Marine Division Evolution - Recent History NucSIG Event – 9th June 2010 • Changing our approach: – – – – – Marine Division Supplier Development Programme (SC21) Shared Supplier Intelligence Integrated Supplier Assessment Shared Supplier Performance Monitoring Assessor Training & Development