CHE 333 Class 19

advertisement

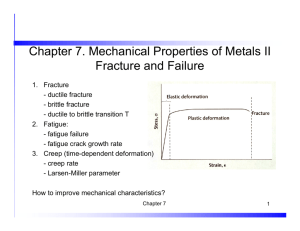

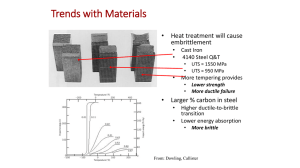

CHE 333 Class 18 Fracture of Materials Ductile or Brittle Failure Following elastic deformation, two different processes can occur – plastic deformation leading to ductile failure or movement to brittle fracture with little or no plasticity. The stress strain curve is shown for ductile failure. After the UTS the ductility is shown by the necking of the material. This would only be for round bar. The stress strain curve for brittle materials is indicated, which would be for glass and ceramics. Brittle Failure SvS stops here Fracture Processes Ligament of material Stretches between voids For ductile materials which have plasticity once the neck starts, a sequence of structural changes occurs as the metal proceeds to failure. Internally voids are initiated . Both the true stress and strain are both still increasing. With further increase in strain the voids become larger, as they become circular or ellipsoidal in shape. The small ligaments of metal between the voids eventually tears and an internal crack is initiated. With further true stress and strain increase the last areas to fail are those connecting the internal crack to the surface. A “shear lip” at 45o to the surface characterizes this region leading to “cup and cone” fracture in rod. Micro Failure Processes. In single phase materials, small voids appear at the cell walls as each dislocation effectively carries a vacancy with it. These voids then grow with further stressing Micro Failure Processes In two phase material, several different micro processes can lead to void initiation growth and failure. If the second phase is either large or continuous, then a dislocation pile up in one phase will lead to a void formation. This will then grow in phase. The second phase will have strengthened the material but will also have eventually initiated the failure process. Examples include pearlitic steels and other platelet structures such as those in titanium alloys Second Phase 45o Void from dislocation pile up on slip plane s Micro Failure Example Example of toughened material? Micro Failure Processes When the second phase is small and non discontinuous, other processes in addition to dislocation pile up and a void on the slip plane are possible. The controlling factors are the strength of the second phase particle and interface between the second phase and the matrix material. If the second phase is weaker or more brittle than the matrix, then the second phase particle may crack. Age hardened aluminum alloys behave in this manner Micro Failure Example Al 7079 Age Hardened alloy showing particle failure. Micro Failure Examples Macro View of Failure Fracture Surface Features Ductile failure in a titanium alloy which is two phase showing dimples from void formation Final Failure in Shear Lip Shear dimples in area of shear lip. Brittle Failure Fracture Surface A faceted type of fracture surface is often seen with a brittle failure as cracks are on a single crystal plane, no shear lip would be found.. Fracture Mechanics. Originally to explain why glass has low toughness where toughness is the ability to resist crack growth in a material. Simple energy balance used – energy applied is the stress and it is used up by creating fresh surface. Works well for brittle materials where no plastic deformation. For ductile materials energy absorbed is complicated by plastic deformation. Fracture mechanics relates the size of a defect in the material to the stress is can withstand before failure. Kc = Ysc (pa)0.5 Mode I II III Plane Strain Fracture Toughness Ductile to Brittle Transition In some materials, mainly steels, ductility can decrease very sharply with temperature, so a ductile materials becomes brittle – know as the ductile brittle transition. The standard test is to use an impact tester – a pendulum type hammer and the energy absorbed in failure is measured by how far the hammer swings through after impact – the further the less energy. Shear ratio to impact energy Carbon content effect on DBTT for Steels Homework 1. For a material with a single crystal yield strength of 300 MPa, calculate the yield strength for a grain size of 50 micron and for a grain size of 2.5 microns. Assume k =1 2. Decide the crack initiation process in a tensile test for the following conditions:Matrix shear strength Matrix Normal Strength Interface Strength Particle Strength a b c d Data units MPa. 25 55 55 45 60 50 60 55 35 60 35 45 55 60 45 35