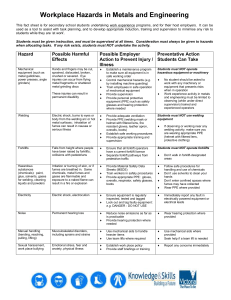

Welding Safety

advertisement

Welding Safety WY MSHA State Grant Program Welding Welding joins two pieces of metal by the use of heat, pressure, or both Brazing or soldering involves a filler metal which has a lower melting point than the metal pieces to be joined Metal cutting is done by heating the metal with a flame and directing a stream of pure oxygen along the line to be cut Welding Arc Welding Shielded Metal Arc Welding (SMAW) Metal Inert Gas (MIG) Tungsten Inert Gas (TIG) Plaza Arc Welding (PAW) Submerged Arc Welding (SAW) And Many More…..more than 80 in all Health Hazards Gases and Fumes… Welding “Smoke” is a mixture of very fine particles called fumes and gases Welding “Smoke” contains fumes and gases including… Chromium, nickel, arsenic, asbestos, manganese, silica, beryllium, cadmium, nitrogen oxides, phosgene, acrolein, flourine compounds, carbon monoxide, cobalt, copper, lead, ozone, selenium, and zinc Health Hazards…Gases & Fumes Generally, gases and fumes come from… Base material & filler material Coatings & paints Shielding gases & chemical reactions Process & consumables used Contaminants in the air Health Hazards It is difficult to list all the health effects of welding exposures because the fumes may contain so many different substances that are known to be harmful The individual components of welding “smoke” can affect just about any part of the body, including the lungs, heart, kidneys, & central nervous system Health Hazards Exposure to welding “smoke” may have… Short-term effects… Effects happen at or very soon after exposure Long-term effects Effects may happen after repeated overexposures or an extended time after the exposure Short-term exposures Exposure to zinc, magnesium, copper and copper oxide can cause metal fume fever Symptoms of metal fume fevere may occur 4 to 12 hours after exposure Symptoms include… Chills, thirst, fever, muscle ache, chest soreness, coughing, wheezing, fatigue, nausea, and metallic taste in mouth Short-term exposures Welding “smoke” can irritate the eyes, nose, chest and respiratory tract Welding “smoke” can cause coughing, wheezing, shortness of breath, bronchitis, pulmonary edema, and pneumontis Welding “smoke” can cause nausea, loss of appetite, vomiting, cramps, and slow digestion Short-term exposures Exposure to cadmium can be fatal in a short time Ultraviolet radiation can react with oxygen and nitrogen to form ozone and nitrogen oxides These gases are deadly at high concentrations and can also cause irritation of nose and throat and cause serious lung disease Short-term exposures Ultraviolet rays given off by welding can react with hydrocarbon solvents such as… Trichloroethylene; 1,1,1-trichloroethane; methylene chloride; & perchloroethylene to form phosgene gas Even a very small amount of phosgene gas may be deadly Early symptoms include dizziness, chills, and cough and usually take 5 – 6 hours to appear Short-term exposures Arc welding should never be performed within 200 feet of degreasing equipment or solvents Long-term exposures Studies of welders, flame cutters, and burners have shown that welders have an increased risk of lung cancer… and…possibly cancer of the larnyx and urinary tract Remember… welding “smoke” can include cancer causing agents such as…cadmium, nickel, beryllium, chromium, and arsenic Long-term exposures Welders may experience a variety of chronic respiratory problems, including… Bronchitis, asthma, pneumonia, emphysema, pneumoconiosis, decreased lung capacity, silicosis, and siderosis Long-term exposures Other health problems… Heart disease, skin diseases, hearing loss, chronic gastritis, gastroduodentis, and ulcers of the stomach and small intestine Reproductive risks Other Health Risks… Heat exposure… Heat stress, heat stroke burns, eye injuries from hot slag, metal chips, sparks, and hot electrodes Other Health Risks… Visible light, and ultraviolet and infrared radiation Intense light can cause damage to retina Infrared radiation may damage the cornea and result in cataracts Invisible UV light can cause “arc eye” or “welders’ flash” May include sandy or gritty eye, blurred vision, intense pain, tearing, burning and headache Other Health Risks… Permanent eye damage Skin burns Skin cancer Noise Can result in stress, increased blood pressure, may contribute to heart disease, tiredness, nervousness, and irratability Musculoskeletal Injuries Back injuries, shoulder pain, tendonitis, reduced muscle strength, carpal tunnel syndrome, white finger, and knee joint diseases Injuries may be caused by overhead work, vibration and heavy lifting Electrical Hazards Even though welding generally uses low voltage, there is still a danger of electric shock Wet work areas, Cramped work spaces Falls, fractures and other accidents can result from electrical exposure Even small shock can cause brain damage Death can occur from large shocks Electrical Hazards Always use dry gloves Always wear rubber soled shoes Always use insulating layers Protect yourself from surfaces that conduct electricity When working on electrically powered machinery, make sure the frame is grounded Keep insulation on all welding equipment and components dry and in good condition Don’t change electrodes with bare hands, wet gloves or while standing on wet or ungrounded surfaces Fire and Explosion Hazards Intense heat and sparks can cause fires or explosions if in the vicinity of combustible or flammable materials Welding and cutting should only be performed in areas free of combustible materials such as trash, wood, paper, textiles, plastics, chemicals, and flammable dusts, liquids and gases Fire and Explosion Hazards Never weld or cut on containers that have held a flammable or combustible material unless the container is thoroughly cleaned or filled with an inert gas A fire inspection should be performed prior to leaving a work area and for at least 30 minutes after the operation is completed Fire extinguishers should be nearby, of proper size, type and number for the hazards involved Dangerous Machinery All machines in the area with moving parts must be guarded to prevent worker’s contact Hair, clothing, fingers, etc. When repairing machinery by brazing and welding, power must be disconnected, locked out, and tagged so the machinery cannot be started up accidentently Trips and Falls To prevent trips and falls… keep work areas clear of equipment, machines, cables, and hoses Always properly maintain and use handrails Always use and maintain safety lines, harnesses and lanyards Always make sure that scaffolds are properly assembled and used Welding Hazards in Confined Space A work area with limited access, little or no airflow, not intended for continuous occupation May also have dangerous atmospheres, hazardous configurations, or other hazards All employees working in or around confined space must be trained Welding Hazards in Confined Space Never weld or cut in explosive, flammable, combustible or other dangerous environments Always use all necessary Personal Protective Equipment (PPE), including, harness and lanyard, respiratory protection, eye protection, etc. Never work in confined space without a trained attendant Welding Hazards in Confined Space Always leave gas cylinders and welding power sources outside the confined space… Only take hoses or welding leads into confined space Always removed hoses and/or leads when leaving confined space for breaks, shift or crew changes, etc. Welding Hazards in Confined Space No worker should work in an area with less than 19.5% or more than 23.5% oxygen content Never ventilate with oxygen Use continuous mechanical ventilation and proper respiratory protection All pipes, ducts, power lines, etc. that are not necessary for the work should be disconnected/locked out/tagged out Compressed Gas Hazards Gas welding and cutting use a fuel gas and oxygen which are stored in high pressure cylinders Most fuel gases are explosive Pure oxygen will increase the flammability of any combustible/flammable material Compressed Gas Hazards All cylinders should have caps or regulators Pressure regulators must be designed for gas in use Check all equipment and components prior to use Cylinders must be stored upright and secured Oxygen and fuel gas cylinders must be stored separately Be aware of flashbacks and backfires?? Close cylinder valves when work is completed or left unattended during breaks, etc. Reducing Noise Hazards Identify hazards and potential hazards prior to beginning hot work Read the MSDS sheet to identify the hazardous material used in welding and cutting products, and the fumes that may be generated Make sure that you know what you are welding before beginning Cadmium exposure can be fatal in a very short time Compressed Gas Hazards After a specific hazard(s) has been identified… you can implement appropriate control method(s) You can use appropriate PPE Engineering Controls and Work Practices Substitute less hazardous materials for hazardous materials Use cadmium-free silver solders Use asbestos- free electrodes, gloves, and hot pads Use ventilation to move away or dilute hazards Use work area barriers to protect others working in the same general area Engineering Controls and Work Practices Welding booths should be painted with dull finishes so they don’t reflect UV light Acoustic shields between the worker and noise sources can reduce exposures Noisy machinery can be totally enclosed Engineering Controls and Work Practices Modify the process or follow safe work practices so that hazards are eliminated or reduced to the minimum… Don’t weld on painted surfaces; use water table under plasma arc cutting to reduce noise; Grind instead of airarcing; use sub arc; position yourself away from fumes; remove nearby flammables/combustibles; properly maintain equipment; proper housekeeping; use lowest possible amperage; hold electrode perpendicular and close to work surface Never weld or cut within 200 feet of degreasing equipment or solvents Personal Protective Equipment (PPE) PPE must be used in conjunction with engineering controls and safe work practices Use of one does not eliminate the need for the other Eye protection should be used in all welding operations Wear face shields or helmets and goggles or safety glasses Use appropriate filters on eye protection Filter Lens Shade Numbers SMAW – 1/16 - 5/32 = #10 Gas SAW - 1/16 - 5/32 = #11 (nonferrous) Gas SAW – 1/16 – 5/32 = #12 (ferrous) SMAW – 3/16 – ¼ - = #12 5/16 & 3/8 electrodes = #14 Atomic Hydrogen Welding = #10 - #14 Carbon Arc Welding CAW = #14 Filter Lens Shade Numbers Soldering = #2 Torch Brazing = #3 or #4 Light cutting up to 1 inch = #3 or #4 Medium cutting 1 inch to 6 inches = #4 or #5 Heavy cutting over 6 inches = #4 or #6 Light gas welding up to 1/8” = #4 or #5 Medium gas welding 1/8” to ½ “ = #5 or #6 Heavy Gas Welding over ½ “ = #6 or #8 Protective Clothing Fire resistant gauntlet gloves Headcap High top hard toed shoes Leather apron Faceshield Flame retardant clothing Safety Glasses Safety helmet Hearing Protectors Ear plugs and/or muffs should be worn during noisy operations such as air arcing or grinding Most welding operations are noisy Respirators Must be specific to the hazard Must be fitted, cleaned, stored and maintained in accordance to regulation and manufacturers specs NIOSH recommends respirators whenever a carcinogen is present