Food and Beverage Management

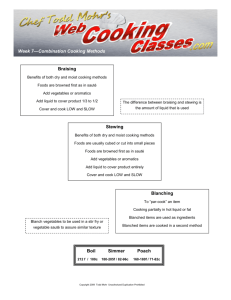

advertisement

Food production: systems eg traditional, batch cooking, call-order, centralized, assembly kitchens, sous-vide, cook-chill, cookfreeze Where does food production happen? In our Kitchen ! Fine ! Where are food produced commercially ? the food industry is a complex, global collective of diverse businesses that supply much of the food and food energy consumed by the world population. The food industry includes: Regulation: local, regional, national, and international rules and regulations for food production and sale, including food quality, food safety, marketing/advertising, and industry lobbying activities Education: academic, consultancy, vocational Research and development: food technology Financial services: credit, insurance Manufacturing: agrichemicals, agricultural construction, farm machinery and supplies, seed, etc. Agriculture: raising of crops and livestock, and seafood Food processing: preparation of fresh products for market, and manufacture of prepared food products Marketing: promotion of generic products (e.g., milk board), new products, advertising, marketing campaigns, packaging, public relations, etc. Wholesale and distribution: logistics, transportation, warehousing Retailing Mass production: This method is used when there is a mass market for a large number of identical products, for example chocolate bars, ready meals and canned food. The product passes from one stage of production to another along a production line. Just-in-time (JIT) (production: This method of production is mainly used in restaurants, sandwich delicatessens ,pizzerias, and sushi bars. All the components of the product are available in-house and the customer chooses what they want in their product. It is then prepared with fresh ingredients in front of the buyer. One off production: This method is used when customers make an order for something to be made to their own specifications, for example a wedding cake. The making of one-off products could take days depending on how intricate the design is and the ability of the chef involved. Batch production: This method is used when the size of the market for a product is not clear, and where there is a range within a product line. A certain number of the same goods will be produced to make up a batch or run, for example a bakery may bake a limited number of a specific baked good. This method involves estimating the number of customers that will want to buy that product. This is the type of service used to provide room service meals in a hotel. It requires less equipment than for an a la carte operation. The menu is normally restricted in size and scope, and is commonly made up of convenient, easy to prepare foods. Typical equipment needed might be refrigerators, grills, toasters, deep fryers, microwaves and ovens. Centralized Production Methods • Involve the separation of the production and service components. • Food that is centrally produced is either then distributed to the point of service in batches or is pre-portion; it may be transported in a ready-to-serve state. • Food production storage and regeneration method utilizing principle of low temperature control to preserve qualities of processed foods. Low temperature conditions above freezing point, 0-3c • Reheating immediately before consumption. • Require low capital investment and minimum staff. • Production, storage and regeneration method utilizing principle of freezing to control and preserve qualities of processed foods. • Required special processes to assist freezing e.g. sauces reheat when needed • Require high speed low temperature at least -20C w/in 90 mins Method of production, storage and regeneration utilizing principle of sealed vacuum to control and preserve the quality of processed foods. Individual portions of prepared food are placed in a special plastic pouches. Sous-vide is a form of cook-chill: a combination of vacuum sealing in plastic pouches, cooking by steam and then rapidly cooking and chilling. The objective is to rationalize kitchen procedures without having a detrimental effect on the quality of individual Dishes. Watch Video • Vacuum pressures are as important as the cooking temperatures with regard to weight loss and heat absorption. The highest temperature used in sous-vide cooking is 100°C (212°F) and 1000 millibars is the minimum amount of vacuum pressure used. • As there is no oxidation or discoloration it is ideal for conserving fruits, such asapples and pears, for example pears in red wine, fruits in syrup. When preparing meats in sauces the meat is pre-blanched and then added to the completed sauce. • Sous-vide is a combination of vacuum sealing, tightly controlled en papillote cooking and rapid chilling. http://web.zone.ee/eda/uued/cookchill-mini-guide-491_3b.jpg http://en.wikipedia.org/wiki/Galley_(kitc hen)#mediaviewer/File:Air_Canada_Airb usA340_Kitchen.jpg http://transformingcommunities.org/category/tags/centrali zed-food-production http://nptel.ac.in/courses/103107088/mo dule23/lecture2/lecture2.pdf