Sampling Procedures: ISO 2859 Inspection by Attributes

advertisement

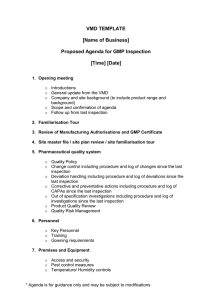

Implement sampling procedures FDFOPTISP2A Prepare for sampling Identified in accordance with the sampling plan Prepare Sampling equipment, containers and labels Collect samples Collect samples according to procedures and the requirements of the sampling plan •Collect samples taking account of OHS mearures to contol risk of injury Control of Occupational Injury The control of occupational injury and disease risks should preferably be dealt with in a preferred order or hierarchy. The control measures range from the most effective to the least effective. The Hierarchy or Preferred Order of Control is: next slide Hierarchy or Preferred Order of Risk Control Elimination Substitution Isolation Engineering Control Administrative Control - Personal Protective Equipment Basic Priciple Change work not worker Manual Powder Sampling With a range of powder samplers, you can sample anything from normal free flowing powders to cohesive sticky powders. Sack Master The Sack Master has been specially designed to take samples through the side of a sack. Manual Liquid Sampling Sampling with an Environmental sampelrs Cream and Paste Sampling Taking cream and paste samples has never been easy or quick. Handle Samples Samples must be handled and prepared to preserve sample and source integrity Defects or abnormalities in source material and/or sample must be identified and reported Sample information is to be recorded according to workplace sample recording requirements The workplace must meets housekeeping standards Sampling Procedures Inspection by Attributes ISO15378 - GMP PS9004 EN-ISO 9001 –QMS Military Standard 105E Sampling Codes BS 6001-1 1999 (ISO 2859-1:1999) Sampling procedures for inspection by attributes. Part 1: Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection. ISO 2859-2:1985 Sampling procedures for inspection by attributes. Sampling plans indexed by limiting quality (LQ) for isolated lot inspection. ISO 2859-0:1995 - Part 0: Introduction to the ISO 2859 attribute sampling system. Sampling procedures - Inspection by Attributes – p.2/23 ISO 2859 Part 1 Acceptance sampling system for inspection by attributes. It is indexed in terms of acceptance quality level (AQL) Aim - to induce a supplier to maintain a process average at least as good as the specified acceptance AQL, whilst at the same time providing an upper limit for the risk to the consumer of accepting the occasional poor lot. Applicable to end products, raw materials, operations, maintenance operations, administrative procedures. Usage of the Part 1 scheme. Intended to be used for a continuing series of lots,which will allow the application of switching rules. The rules provide: – protection to the consumer should a deterioration in quality be detected. – an incentive to the supplier to reduce inspection costs should consistently good quality be achieved. Can also be used for inspection of lots in isolation. Terminology Inspection by attributes: inspection where an item is classified as conforming or nonconforming with respect to a specified requirement or set of requirements. Nonconformity: Non fulfillment of a specified requirement. Usually classified according to the degree of seriousness. More serious nonconformities will usually be assigned a very small AQL, whilst less serious nonconformities will be assigned higher AQL values. Terminology (cont) Normal inspection: Use of a sampling plan with acceptance criteria devised to secure the producer a high probability of acceptance when the process average of the lot is better than the AQL. Used when there is no reason to suspect the process average differs from an acceptable level. Tightened inspection: Use of a sampling plan with an acceptance criteria that is tighter than that for the corresponding plan for normal inspection. Invoked when the inspection results of consecutive lots indicate that the process average might be poorer than the AQL. Terminology (cont) Acceptable Quality Limit (AQL): Quality level that is the worst tolerable process average when a continuing series of lots is submitted for acceptance sampling. AQL does not mean ’desirable level’. ISO 2859 is designed to encourage suppliers to have process averages consistently better than the AQL, otherwise thereis a risk of switching to tighter inspection. Terminology (cont) The designation of an AQL does not imply that the supplier has the right knowingly to supply any nonconforming items: AQL values shall not exceed 10% nonconforming. When the quality level is expressed as number of nonconformities per 100 items, AQL values up to 1000 nonconformities per 100 items may be used. Sampling: – Sample selection must be drawn from the lot by simple random sampling. – When double or random sampling is to be used, each subsequent sample shall be selected from the remainder of the same lot. Inspection Levels 4 special inspection levels - S1, S2, S3, S4. 3 general inspection levels - I, II, III. Special inspection levels used when sample size must be kept small and larger sampling risks can be tolerated. Level II will be used unless another inspection level is specified. Level I is used when less discrimination is required, Level III when greater discrimination is required. Sample size code letters Sample size code letters (cont) Single Sampling Plans Double Sampling Plans Normal Inspection OC Curves Operating Characteristic Curves – OC curve is a graph showing what any particular sampling plan can be expected to do in terms of accepting and rejecting batches. – An understanding of the implications of an OC curve helps understand the risks to the manufacturer, consumer, and in deciding inspection levels and batch sizes. – Each possible plan has its own OC curve. – Horizontal scale - shows the percentage defective. Vertical scale - shows the percentage of batches that may be expected to be accepted if batches are produced with that percentage of defects. Using an OC curve Interpret the curve according to this example: •If the lot quality is 0.093 fraction defective, then the probability of acceptance, Pa, is 0.05. •If the lot quality is 0.018 fraction defective, then the probability of acceptance, Pa, is 0.95. Alternative OC for Sample plans You can use oc-curves to compare alternative plans. Choose between the plans by their relative ability to detect rejectable lots. You should expect that the steeper the curve, the larger the sample size. OC Curves OC Curve Example Code Letter M AQL 1.5 Sample size - 315 Accept: 10, Reject: 11 What happens if a batch with 3% defectives is submitted ? Find 3% on the X axis, and follow a vertical line up until it meets the 1.5% curve. Take a horizontal line across to the Y axis, and read off the value of 65%. I.e., 65% of batches would be accepted and 35% rejected. More OC curve examples Statistical Quality Control Online http://iew3.technion.ac.il/sqconline/milstd105 .html This application gives the single and double sampling plans for attributes, according to the Military Standard 105E tables, for a given lot size and AQL Example of Online Calculation Result Single sampling The Double sampling Results Even gives the OC curve The OC curve describes the probability of accepting a lot, OC(p), as a function of the proportion nonconforming (p), Concrete examples EN 455 Part 1 for medical gloves - Pinholes – General inspection level 1, AQL 1.5%. – Minimum sample size code letter L (200 gloves) – If a batch with 3% pinholes is submitted, there is a 75% chance of them being accepted. All Wales Universal Container contract – Agreed AQL of 0.65%, general Inspection level I. – Sample code L (200 samples). – If a batch with 5% leakers is submitted, there is a 99% chance of them being rejected. Setting an Inspection Level Select the required AQL (as an average). Decide what quality should have a high chance of rejection. Choose the appropriate sampling plan by inspecting the OC curves. Setting an Inspection Level Example An AQL of 1.5% defective items has been chosen. It is desired to have at least an 80% chance of rejecting a 6% defective batch under normal inspection. Code letters A->J fail to meet the requirement. Code letter K almost meets it, codes L-P more than meet it. Decide the batch size. If batch size is 1000, check sample size code letters table - we can use general inspection level III. The sampling plan would therefore be AQL=1.5%, General Inspection Level=III. Switching Rules Normal to tightened: Shall be implemented as soon as two out of five (or fewer than five) consecutive lots have been non-acceptable on original inspection. Tightened to normal: Shall be reinstated when five consecutive lots have been considered acceptable on original inspection. Normal to reduced: implemented when the switching score is at least 30, production is at a steady state, and reduced inspection is considered desirable by the responsible authority. Discontinuation of inspection: is implemented when the number of lots not accepted in a sequence of consecutive lots on original tightened inspection reaches 5. Reduced to normal: if a lot is not accepted or irregular/delayed production. Switching Scores Single Sampling Plans Used when deciding whether to switch to reduced inspection. Set switching score to 0 at start of normal inspection. Score updated following the inspection of each lot. When the acceptance number is >= 2, add 3 to the switching score if the lot would have been accepted if the AQL had been one step tighter; otherwise reset score to 0. When the acceptance number is 0 or 1, add 2 to the switching score if the lot is accepted; otherwise reset score to 0. As in the previous slide, when the switching score is at least 30 and production is at a steady state, switch to reduced inspection if considered desirable by the responsible authority. Important points Setting an AQL does not guarantee to the customer that batches of a worse quality will not be accepted. If the average quality of batches being submitted are a little worse than the AQL, a number of batches will probably be accepted before a switch to tightened inspection is called for. In general, the customer gets a quality which is, on average, better than the AQL, since the tables are arranged to provide an economic incentive the manufacturer cannot afford to have more than a small proportion of batches rejected, and so will improve the quality if this proportion is exceeded.