An Introduction to - Computer Numerical Control

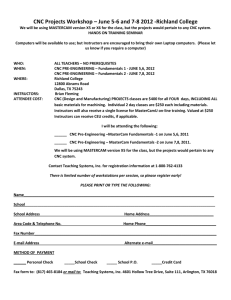

advertisement

An Introduction to Computer Numerical Control Introduction CNC: Computer Numerical Control Production of machined parts whose production is controlled by a computer. Computer uses a controller to drive each axis of the machine tool. (X,Y,Z) Controls direction, speed, and length of time motor rotates. Introduction A programmed path is loaded into the computer and then executed. Program consists of numeric point data (X,Y,Z), along with machine control and function commands. Numerical Control (NC) & Computer Numerical Control (CNC) mean the same. Introduction A major manufacturing development in past 60 years. Resulted in: new manufacturing techniques higher production levels higher quality stabilization of manufacturing costs Evolution of CNC Single items produced by craftspeople Interchangeable Parts Eli Whitney (Cotton Gin) Manual labor was still the most cost effective method. WW II manufacturers could not maintain quantity & quality parts. Evolution of CNC Machinists could produce superior quality but not at high volume that was required. As quantity increased, quality decreased due to human factors Evolution of CNC ENIAC – developed by the United States Army Ballistic Research Lab & University of Pennsylvania First digital computer. Vacuum tube technology. (30,000) Used to calculate artillery tables. Programming involved setting hundreds of switches and cables. ENIAC ENIAC CNC & WW II Need to manufacture large amount of products for the war. Need for quantity and quality. U.S. Air Force set up companies to develop and produce NC systems to handle volume and repeatability. Repeatability: the ability to perform the same operation over & over within specified parameters. Specific Goals Increase production Improve quality & accuracy of machined parts. Stabilize manufacturing costs. Speed up production & assembly operations. NC Timeline 1949 - First contract awarded for NC machine. 1951 - servo system for machines developed. 1952 - tape-fed machine was created. History Development of G codes - Punch tape input (Cartesian Coordinate System) 1970’s Development of computer chips Cheaper processing power Smaller computers More reliable Paper Tape Control Paper Tape Control Paper Tape Control Strip of paper tape with holes in it. Machine read pattern of holes and performed the required operation. Paper Tape Control Disadvantages Difficult to identify parts of program. Programs could be quite large. Stored on large bulky reels. Fragile, could rip easily. CNC Further developments in the computer allowed it to be used to control the machine instead of the paper tape. CNC Advantages vs. NC Programs could be stored in computer memory. Easier to edit. More complex parts could be manufactured. Use of 3d geometry. Networking/filesharing w/ other computers. Advantages Of CNC Increased productivity after programming is completed Reliability - reduces human error Often eliminates need for special jigs and fixtures Reduces location of part features Makes possible the machining of complex shapes requiring simultaneous 3 axis motion Advantages Single part and production runs can be programmed and machined with minimum effort and cost. Programs can readily be altered and rerun Reduced inspection costs (more reliable) Once programming, setup and verified the equipment can be operated by a less skilled operator. Disadvantages Initial cost of CNC machine tools Servicing of equipment Larger machines require more space Personnel must be trained in the programming and operation of this equipment. Definitions NC - A method of accurately controlling the operation of a machine tool by a series of coded instructions, consisting of numbers, letters of the alphabet, and symbols that the machine control unit can understand MCU - Machine Control Unit - decodes NC codes to drive and monitor servo motor movements. Definition CNC - Computer Numeric Control - computer provides machine codes to the MCU. Control Systems Open loop system - servo motor driven by pulses without feed back encoders. Closed loop system - servo motor is driven by electrical pulses. An encoder provides feedback to verify machine movements. Resources Fitzpatrick, Mike, Computer Numerical Control Simplified, 1989 Glenco Publishing Company. ISBN 0-02-676410-5 Powers, John Jr., Computer Automated Manufacturing, 1987 McGraw-Hill Book Company. ISBN 0-07-050601-9 Groover, Mikell P. and Zimmers, Emory W., CAD/CAM, Computer Aided Design and Manufacturing, 1984 Prentice -Hall Inc. ISBN 0-13-110130-7 Luggen, William W., Fundamentals of Computer Numeric Control, Third Edition, 1988 Delmar Publishers. ISBN 0-8273-6496-2 CNC Workshop (CD-Rom), Torcomp Publisher. Cost $39.95 – Contact TorComp at 888-561-7521